Thin-wall light steel structure steel pile strip-shaped foundation composite foundation technology

A strip foundation, light steel structure technology, applied in the direction of foundation structure engineering, sheet pile wall, construction, etc., can solve the problems of unsuitable control of the overall settlement of the building, damage to the pipeline inside the building, affecting the normal use, etc., to achieve the occupied area Reduced, integrity-enhanced, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

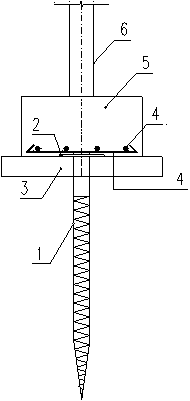

[0023] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0024] Step 1: Carry out steel pile positioning and drilling construction work according to the drawings, and the pile length and pile diameter are selected according to the design drawings;

[0025] Step: 2: After the steel pile 1 is constructed to the design depth, control the pile top flange 2 at the design elevation;

[0026] Step 3: Excavate the strip foundation at a depth of 150mm below the steel pile top elevation;

[0027] Step 4: Pouring 100mm plain concrete cushion 3;

[0028] Step 5: According to the construction drawings, carry out the binding work of the reinforcement bar 4 under the concrete wall;

[0029] Step 6: Seal the strip foundation 5 and pour concrete 5;

[0030] Step 7: After the concrete foundation reaches the design strength, install the upper prefabricated thin-walled light steel structure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com