Wiring groove concrete backfilling equipment for building decoration

A wiring trough and concrete technology, applied in the field of wiring trough concrete backfilling equipment, can solve the problems of low work efficiency, difficulty in controlling concrete voids, cumbersome operation steps, etc., and achieve the effects of increasing backfilling speed, reducing voids, and simplifying working steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

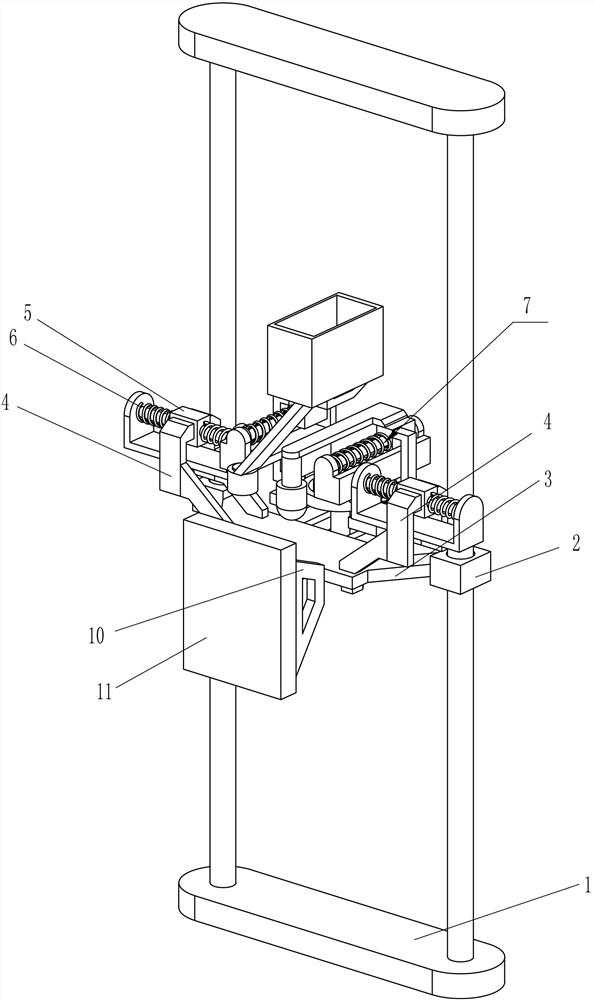

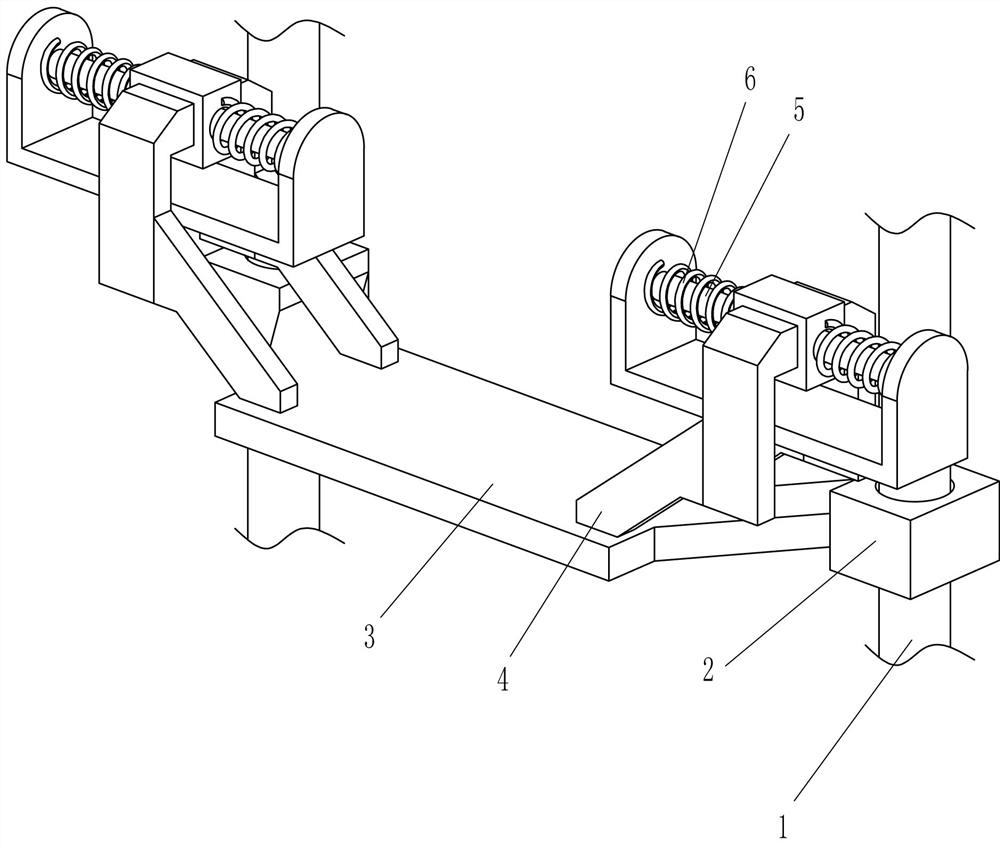

[0025] A wiring trench concrete backfill equipment for building decoration, such as Figure 1-4 As shown, it includes a mounting frame 1, a first moving pair 2, a fixed frame 3, a connecting block 4, a second moving pair 5, a first elastic member 6, a feeding device 7 and a driving device 8, specifically:

[0026] Mounting frame 1 quantity is two groups, is connected with two groups of first mobile pair 2 between mounting frame 1, is connected with fixed frame 3 between the mobile parts of first mobile pair 2, and fixed frame 3 upper side front and rear sides are all connected with The connecting block 4 is connected with the second mobile pair 5, the second mobile pair 5 is connected with the first elastic member 6, and the moving parts of the second mobile pair 5 are provided with a feeding device 7 and a fixed frame 3 The right side is provided with a driving device 8, and the driving device 8 cooperates with the feeding device 7.

[0027] When it is necessary to backfill ...

Embodiment 2

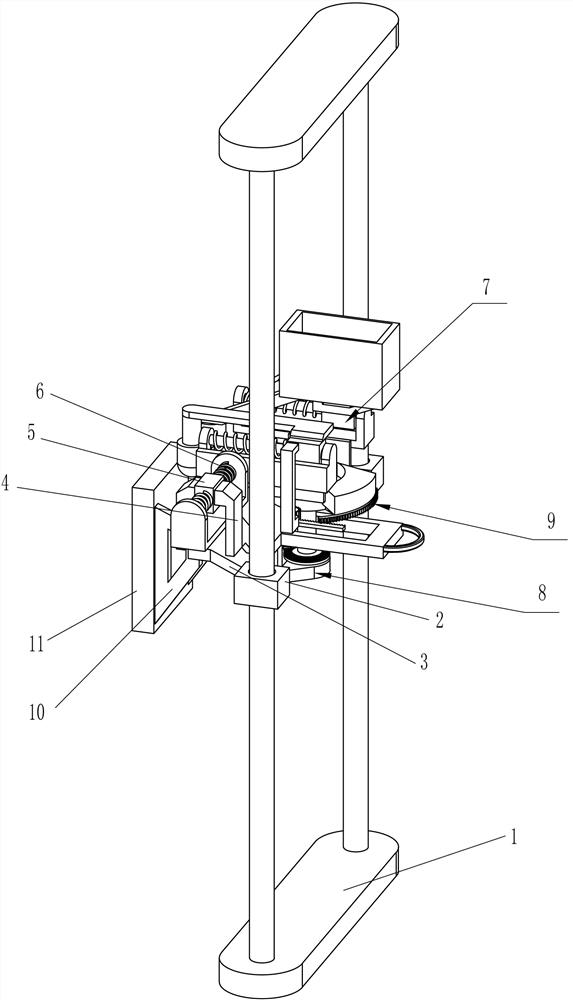

[0029] On the basis of Example 1, such as Figure 5-7 As shown, the feeding device 7 includes a third moving pair 71, a second elastic member 72, an extension rod 73, a vibration block 74, a concrete box 75 and an electric control valve 76, specifically:

[0030] The inner side of the moving part of the second moving pair 5 is connected with the third moving pair 71, the third moving pair 71 is connected to each other, the third moving pair 71 is connected with the second elastic member 72, the movement of the third moving pair 71 on the front side Part upper side is connected with extension rod 73, and extension rod 73 left side is connected with shock block 74, is connected with concrete box 75 on the mobile part of rear side the 3rd moving pair 71, and concrete box 75 lower left side is connected with electric control valve 76.

[0031] When the driving device 8 is working, the driving device 8 will first contact the third moving pair 71 on the front side, and the driving d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com