In-situ dynamic separation backfill device for submarine natural gas hydrate

A technology for hydrates and natural gas, which is applied to the driving device for drilling in boreholes, underwater drilling, and drilling with liquid/gas jets, etc. It can solve the problems of low separation effect, limited processing capacity, and slow backfilling speed. Small structure, fast backfill speed, and the effect of backfill speed protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

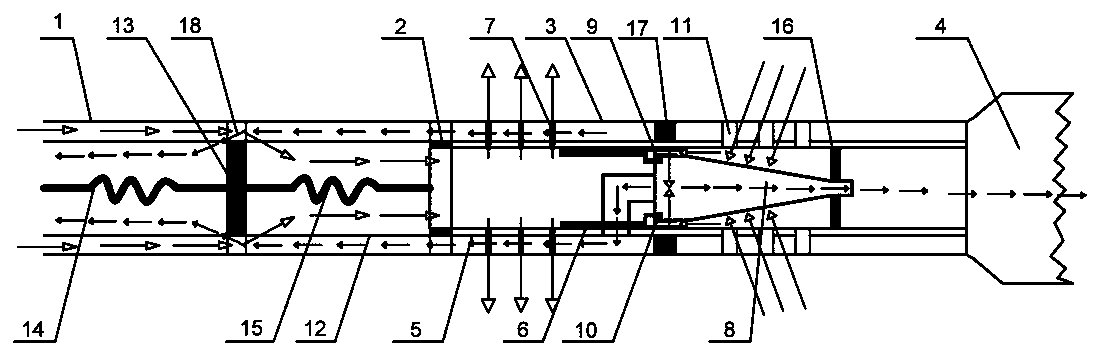

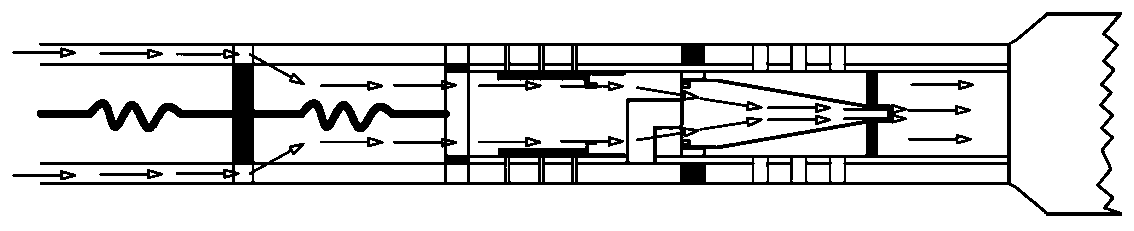

[0021] Such as figure 2 As shown, at the beginning, the drilling fluid is injected into the pipeline gap of the upper double-layer pipe 12, and the drilling fluid enters the inner pipe of the conversion joint 13 and the dynamic sealing joint 2 through the bridge channel 18 provided, and drives the screw motor 15 to rotate. Drive the dynamic separation and backfill system 3 at the back end and the drill bit 4 to rotate. Since the dynamic sealing joint 2 is hollow, the drilling fluid enters the dynamic separation and backfill system 3 and enters the separator 8 from the flow hole 9. The outlet at the lower end enters the drill nozzle of the drill bit 4 to realize the drilling process of the drill bit.

[0022] Such as figure 1 , 2 As shown, after the drilling process of the drill bit is completed, the seawater enters the dynamic separation and backfill system 3 from the pipeline gap of the upper double-layer pipe 12 through the bridge channel. Under the action of pressure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com