Novel composite curing agent for heavy metal Cd contaminated soil and use method of novel composite curing agent

A composite curing agent and polluted soil technology, which is applied in the field of contaminated soil treatment, can solve the problems of affecting soil reuse and high cost, achieve good economic benefits and engineering application prospects, avoid secondary pollution, and reduce the effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

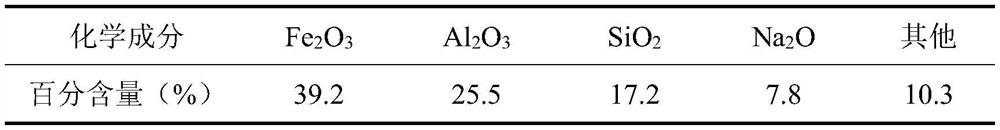

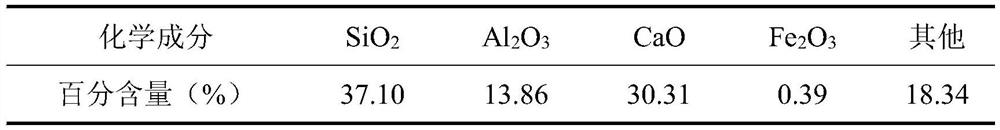

[0034] The components of a novel composite curing agent for heavy metal Cd polluted soil are: red mud and fly ash, and the mixing ratio is 1:1 to obtain a fly ash mixture, alkaline activators NaOH and Na 2 SiO 3 The ratio is 9:1. Combining NaOH with Na 2 SiO 3 Mix evenly in a ratio of 9:1, and dissolve into water to make a solution of 8mol / L, which is used as an alkaline activator. The red mud was obtained from an aluminum plant, dried, ground and passed through a 2mm sieve. The mass percentages of its main components and each component are shown in Table 1. The fly ash was obtained from a coal-fired power plant, dried, ground, and passed through a 2mm sieve. The main components are shown in Table 3.

[0035] The above-mentioned method for using a novel composite solidifying agent for heavy metal Cd-contaminated soil, comprising the following steps:

[0036] (1) excavating, crushing and screening the soil contaminated by heavy metal Cd to be repaired to obtain fine-grained ...

Embodiment 2

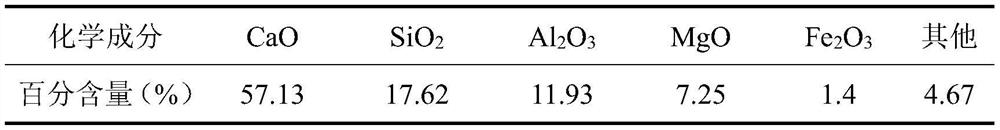

[0041] The components of a novel composite curing agent for heavy metal Cd polluted soil are: red mud and blast furnace slag, and the mixing ratio is 7:3 to obtain a blast furnace slag mixture, alkaline activators NaOH and Na 2 SiO 3 The ratio is 9:1. Combining NaOH with Na 2 SiO 3 Mix evenly in a ratio of 9:1, and dissolve into water to make a solution of 8mol / L, which is used as an alkaline activator. The red mud is the same as in Example 1, and the blast furnace slag is taken from an iron smelting plant, dried and ground and passed through a 2mm sieve, and its main components are shown in Table 2.

[0042] The above-mentioned method for using a novel composite solidifying agent for heavy metal Cd-contaminated soil, comprising the following steps:

[0043] (1) excavating, crushing and screening the soil contaminated by heavy metal Cd to be repaired to obtain fine-grained soil;

[0044] (2) fully mixing the blast furnace slag mixture with the fine-grained soil in a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com