Pressurization thermosensitive vaporization phase change consolidation method and thermal desensitization intermittent evaporator therefor

An intermittent, evaporator technology, applied in vertical tube evaporators, evaporation, steam generation, etc., can solve the problems of low heating efficiency and the inability to realize intermittent heating in the structure of the heating device, so as to improve the bearing capacity of the foundation and accelerate the phase change Consolidation, the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: A pressurized heat-sensitive gasification consolidation method, combined with a method of pressurized vacuum preloading consolidation treatment of soft ground (ZL200810156787.5) and drainage boards, filter cloths and drainage board cores for sludge consolidation ( ZL200910181702.3), including the following steps:

[0044] S1. Place the thermal desensitization batch evaporator in the bottom area of the vacuum preloading drainage plate in the sludge reinforcement area, turn on the heating, and the thermal desensitization batch evaporator sprays high-pressure steam during heating;

[0045] S2. Heating to 200°C, maintaining for 6 minutes, then stopping for 12 minutes,

[0046] Vacuum pressure 90kPa, repeat the above process;

[0047] S3. When the liquid limit index of the surrounding reinforced soil is less than 0.98, stop heating, and the gasification and consolidation is completed.

[0048] With reference to embodiment 1, embodiment 2-5 is as shown in the t...

Embodiment 6

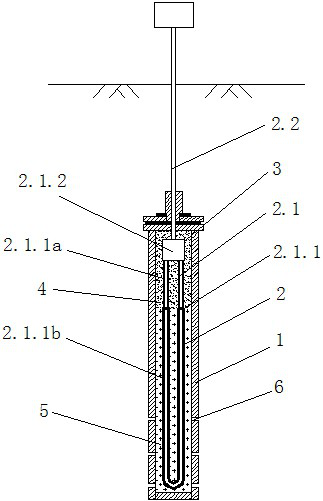

[0050] Embodiment 6: as figure 1 As shown, a thermal desensitization intermittent evaporator for pressurized heat-sensitive gasification consolidation method includes a shell 1, two heating bodies 2 placed in the shell 1, and the heating body 2 includes an electric heating body 2.1 and Connect the wire 2.2 of the electric heating body 2.1, the wire 2.2 is led out of the shell 1 to connect to the power supply, the electric heating body 2.1 includes the heating tube base 2.1.1 and the metal joint 2.1.2 installed on the top of the heating tube base 2.1.1, the metal joint 2.1. 2 Connecting wire 2.2, heating tube base 2.1.1 includes upper and lower bases 2.1.1a, 2.1.1b, upper base 2.1.1a is graphite, lower base 2.1.1b is quartz, upper base 2.1.1a and metal connector 2.1. 1 connection, the entire heating tube base 2.1.1 is formed by pressing and sintering quartz and graphite abrasives, the metal joint 2.1.2 of the heating tube base 2.1.1 is wrapped with high-temperature silica gel 3...

Embodiment 7

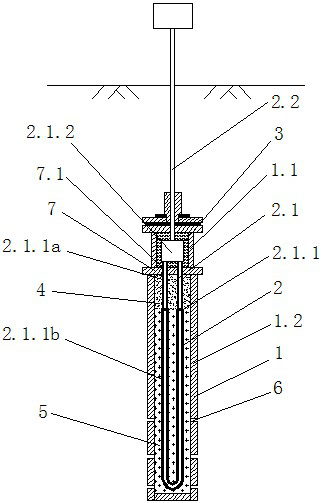

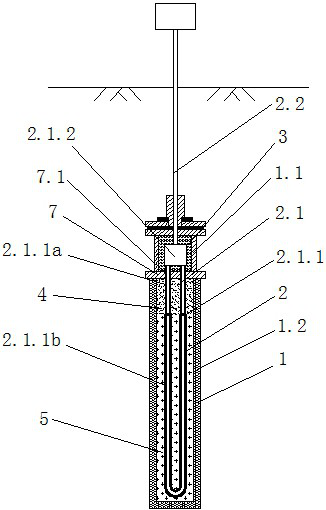

[0051] Embodiment 7: as figure 2 As shown, referring to Example 6, the housing 1 is divided into upper and lower parts 1.1, 1.2, with a partition 7 spaced in the middle, and a plug hole 7.1 is opened on the partition 7, and the heating tube base 2.1.1 is plugged into the plug The connecting hole 7.1 is fixed inside, and the metal joint 2.1.2 is located in the upper part of the housing 1.1. Effectively prevent the base body of the heating tube from breaking due to displacement in the shell, because the refractory material is relatively rigid and easy to break.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com