Construction method for salty soil district railway roadbed with water content higher than liquid limit

A technology for railway subgrade and construction method, which is applied in the directions of roads, roads, buildings, etc., can solve the problems of long construction period of filling subgrade, difficult transportation of fillers, and poor economy, so as to improve overall stability, prevent settlement, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] a. Test the saline soil in the soil borrowing site

[0023] Sampling and testing the saline soil filling in the borrow site, the allowable salt content of the chlorine saline soil is 5.1%, and it can be used as railway subgrade filling after passing the test;

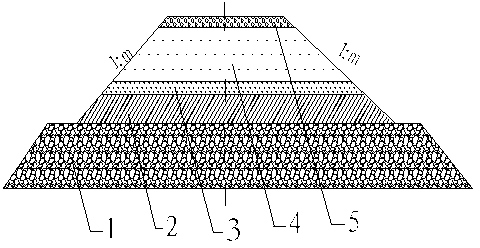

[0024] b. Filling flake layer

[0025] Fill the flake layer (1) on the base. The size of the flakes is 20-40cm. Less than 20% of the smaller flakes are allowed, but the block diameter shall not be less than 15cm. The flakes shall be filled to the design height by mechanical dumping. High, feed materials on both sides first and then in the middle, use Komatsu PC220 excavator for initial leveling, and then use TYG220 bulldozer to bulldoze, the top surface of the flake layer (1) is dense and flat, the side slope is smooth, and the width of the flake layer (1) exceeds the base road surface by 2m , the height is 0.8 meters higher than the weak ground, and a layer of smaller stones is laid on the top of it, and compac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com