Reconstruction method of subsidence hydraulic structure

A technology for hydraulic structures and buildings, applied in building construction, construction, building maintenance, etc., can solve the problems of small space, weak foundation bearing capacity, and high cost, achieve consistent appearance, improve anti-seepage safety, and improve The effect of the duration requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

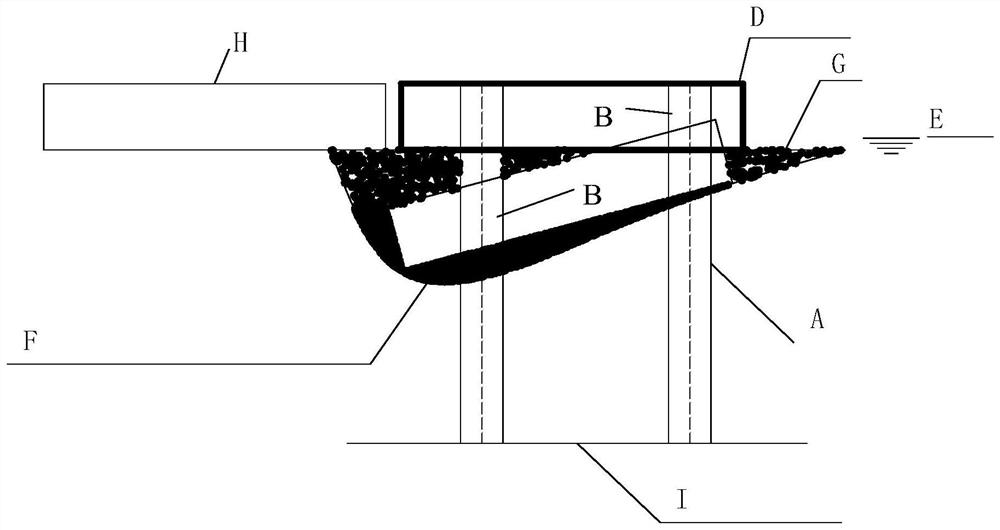

[0054] like figure 1 A method for rebuilding a submerged hydraulic structure as shown, comprising the following steps:

[0055] Step 1. Underwater exploration: explore and check to understand the elevation and plane position of each control point of the subsidence building, and the void at the bottom of the building.

[0056] Step 2. Site treatment: remove sundries, retain existing subsidence buildings, eliminate piping and flowing soil factors, strengthen surrounding foundations with compaction grouting, and strengthen settlement and deformation observation of surrounding buildings.

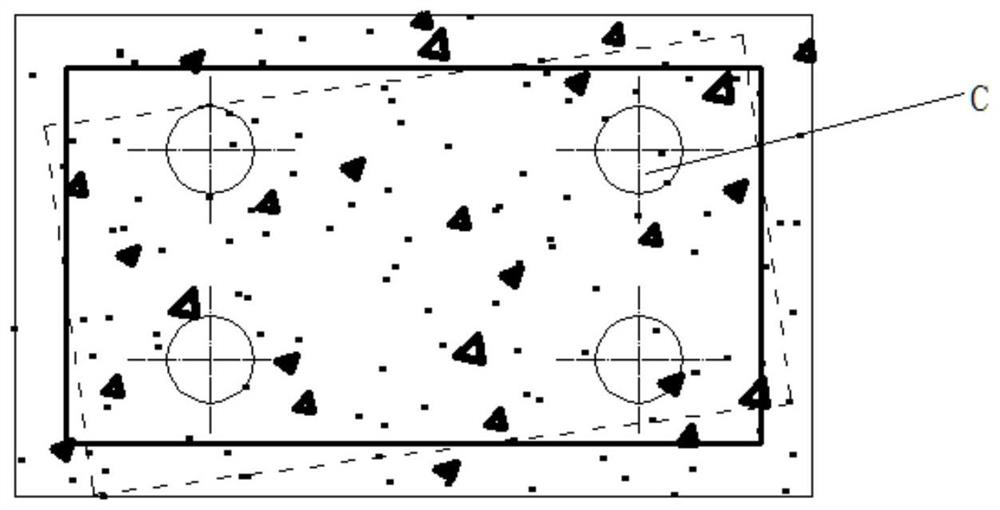

[0057] The specific design of the construction platform is as follows: the construction platform is composed of steel pipe piles + section steel reinforced concrete composite beams and slabs; The full casing equipment is comprehensively determined according to the calculation.

[0058] Step 3. Build the construction platform: Design the construction platform according to the load during the co...

Embodiment 2

[0084] Take the construction of a double-track ship lock as an example. The distance between the double-track ship lock and the first-line ship lock is relatively close, and the geological conditions are extremely complex. The anti-seepage and support system of the foundation pit bears the head water pressure of nearly 15m. Because the anti-seepage system is broken, a piping surge occurs at the bottom of the 3# wing wall of the first-line ship lock. Seepage damage, the river water rushed into the double-track ship lock foundation pit through the bottom of the wing wall, and a large amount of soil at the bottom of the 3# wing wall was brought into the double-track ship lock foundation pit, which eventually caused the 3# wing wall to sink almost completely to below the water surface. The 3# wing wall is about 20m long, 10m wide, 25m high, and sinks more than 10m. On the one hand, it is necessary to rebuild the wing wall, and at the same time, restore the support and anti-seepage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com