Construction method for improving bearing capacity of seawall armor foundation

A technology of foundation bearing capacity and construction method, which is applied in coastline protection, infrastructure engineering, construction, etc., can solve problems such as affecting the stability of seawalls and inconvenient removal of steel sheet piles, shortening the construction period of the project and overcoming the strength of the piles. Low, high ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

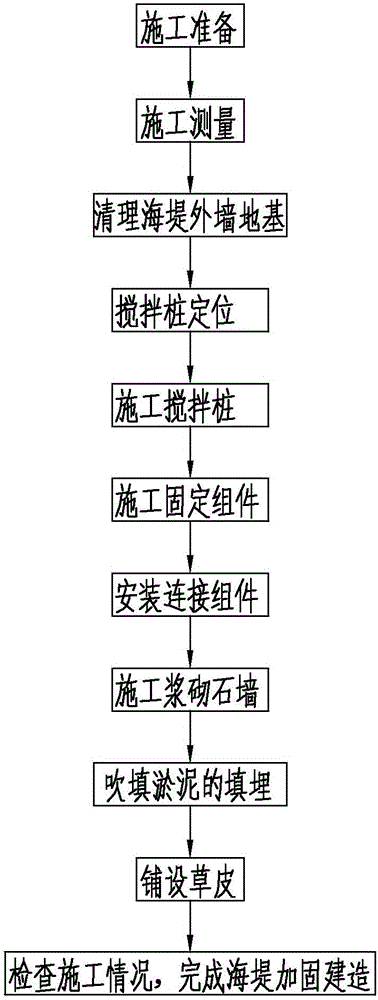

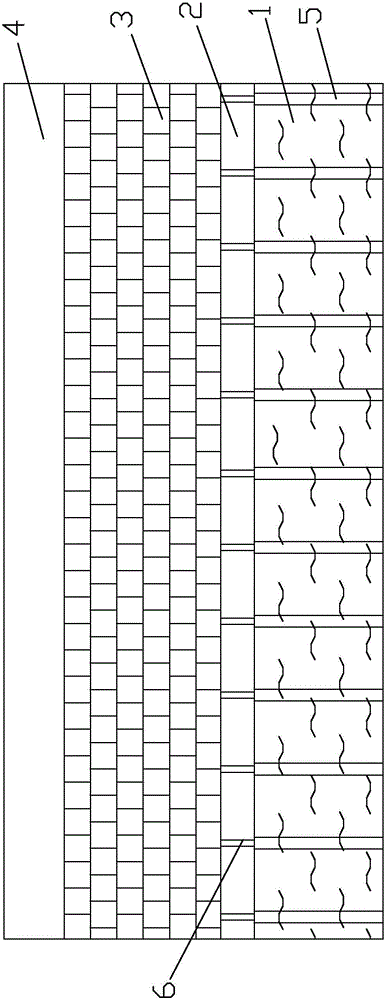

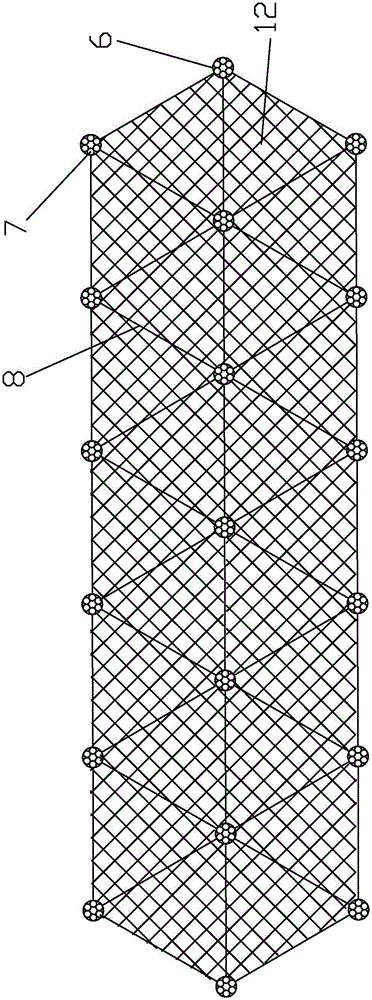

[0038] Such as Figure 1 to Figure 5 As shown, a construction method for improving the bearing capacity of seawall surface protection foundation, comprising the following steps:

[0039] (1) Construction preparation: the specific content of construction preparation: construction personnel master the design intent, transport the equipment and materials required for construction work to the construction site, and prepare for construction; construction preparation includes familiarization with relevant technical design materials, construction drawings and seawalls The technical standards and norms for face protection foundation reinforcement.

[0040] (2) Construction survey: use wire control, set up construction benchmarks and auxiliary construction baselines according to the survey control points and elevation water points of the original seawall, lay wire nets along the main line of the original seawall, and draw engineering drawings, empirical calculations Confirm the constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com