Construction method for grouting reinforcement of urban road roadbed in fly ash accumulation site

A grouting reinforcement, fly ash technology, applied in the direction of roads, roads, infrastructure engineering, etc., can solve the problems of deep compaction effect, urban noise pollution, limited reinforcement depth, etc., to improve the unstable characteristics of engineering, reduce Urban noise factor, the effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

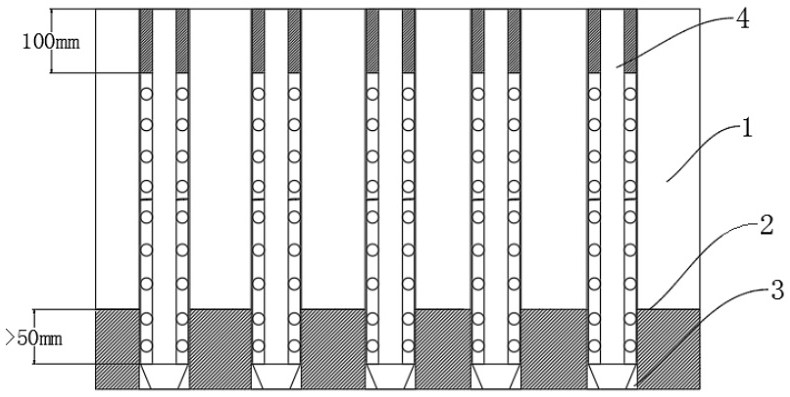

[0028] refer to Figure 1-3 , a grouting reinforcement construction method for urban road subgrades in fly ash accumulation sites, the operation process is as follows:

[0029] Step 1, first establish the construction target position, clean up the site, measure and set out the line to determine the hole position of the grouting hole 3 for piling grouting, and make the grouting pipe 4;

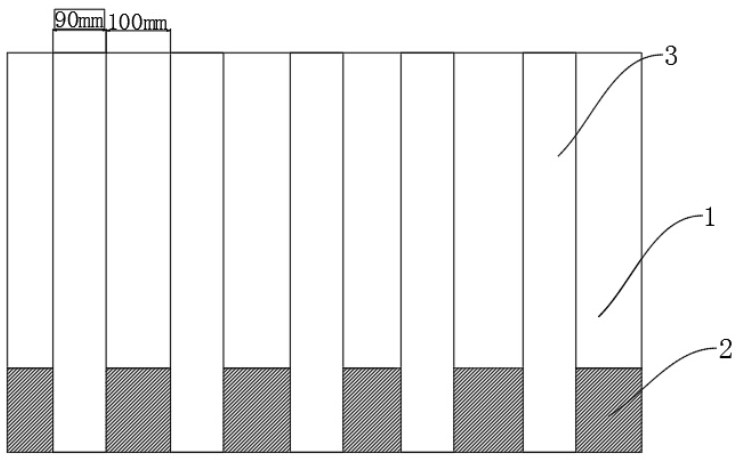

[0030] Step 2: After establishing the position of the grouting hole 3, use an auger drill to form the hole. The depth of the drilled hole is 0.4-0.6m from the fly ash soil layer 1 to the undisturbed soil layer 2, and the diameter and length of the grouting hole 3 range from 80- 100mm, grouting hole 3 spacing 1m, after hole cleaning;

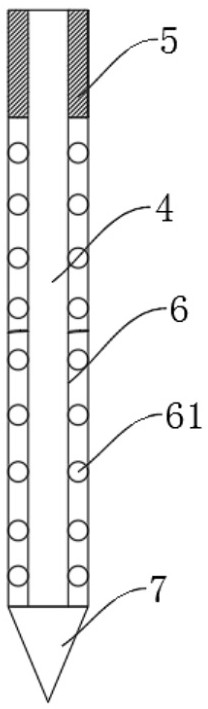

[0031] Step 3, put the cleaned grouting hole 3 into the grouting pipe 4, evenly fill sand around the grouting pipe 4 in the hole, and seal the hole sealing pipe 5 within 1m above the orifice with blended cement mortar. hole;

[0032] Step 4: After grouting and ...

Embodiment 2

[0037] refer to Figure 1-3 , a grouting reinforcement construction method for urban road subgrades in fly ash accumulation sites, which is basically the same as in Example 1. Furthermore, in the specific implementation process, firstly, the construction target position is established, the sundries in the construction site are cleaned, and the measurement is carried out. Set out the distance from the line, determine the hole position of the grouting hole 3 for piling grouting, and make the grouting pipe 4. The grouting pipe 4 is a steel pipe with a diameter and wall thickness of 25mm. The grouting pipe 4 includes the sealing pipe 5 and the sealing pipe 5 The length is 1m, the permeation tube 6 is fixedly connected under the sealing tube 5, and permeation holes 61 are arranged around the permeation tube 6. The permeation holes 61 are opened with 3 holes on the circumference of the permeation tube 6 according to the interval of 500 mm, which is arranged in a plum blossom shape. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com