Comprehensive compacting method for highfill embankment in loess area

A technology for square embankments and areas, which is applied in the field of comprehensive compaction of high-fill embankments in loess areas, can solve the problems that road engineering cannot meet the requirements of the construction period, cannot meet the design requirements, and the effect is not ideal, so as to shorten the pre-compression settlement period , The method is practical and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Comprehensive compaction method for high fill embankment in loess area,

[0015] The steps are:

[0016] (1) Clean the surface of the soil foundation by 30cm and over-excavate by 2m. After the over-excavation, the soil foundation shall be compacted with a heavy hammer to treat the lower foundation, and the effective treatment depth shall not be less than 1m;

[0017] (2) The rammed soil foundation is paved with 6% lime soil with a thickness of 1m and compacted;

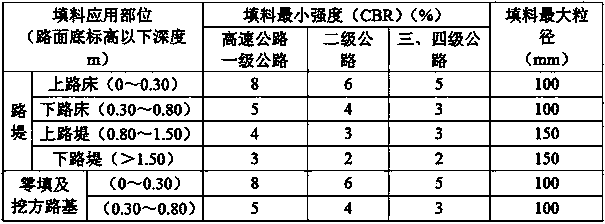

[0018] (3) After the lime soil is paved, the plain soil shall be filled and compacted in layers, and the thickness of each layer of filling shall not exceed 300mm. The compaction shall be carried out with an 18t vibratory roller at a speed of 4km / h, and the compaction coefficient shall not be less than 96%;

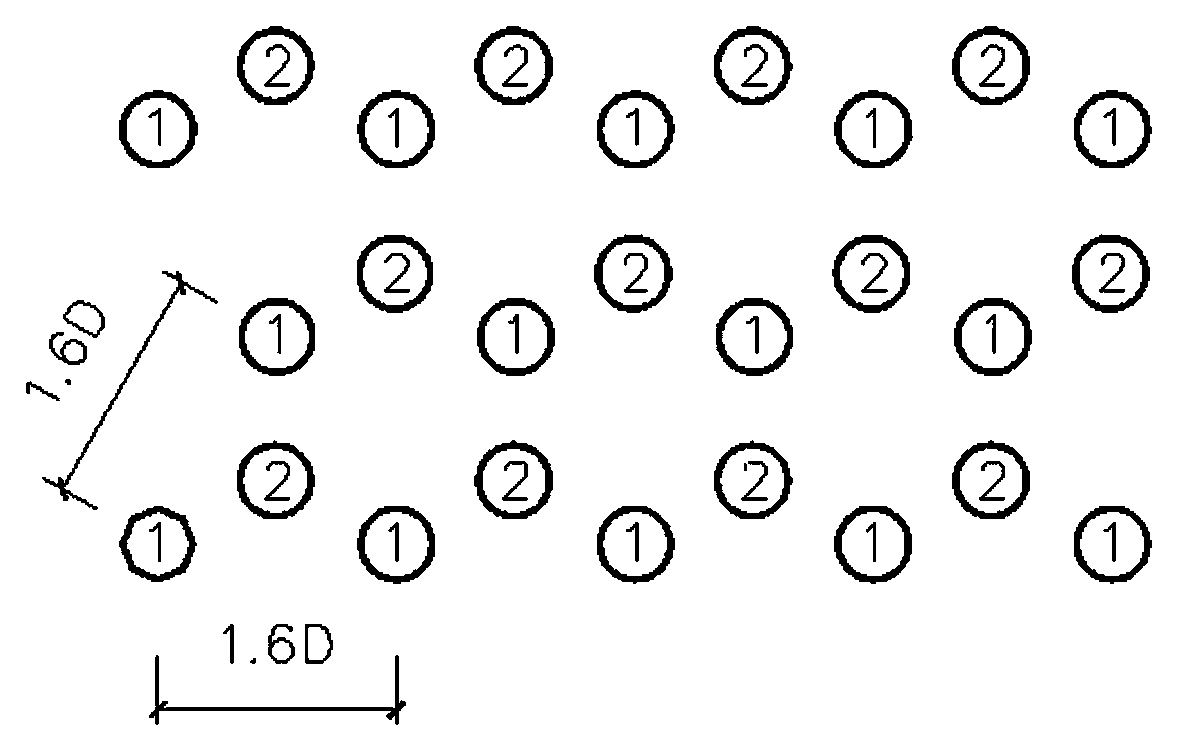

[0019] (4) Use a heavy hammer to tamp and reinforce every 3m of filling;

[0020] (5) Bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com