Construction method for pulling out steel sheet piles close to existing buildings

A technology with existing buildings and construction methods, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as underground structure hazards, affecting the normal use of adjacent buildings, roads and underground pipelines, and achieve project cost savings , good reinforcement effect and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

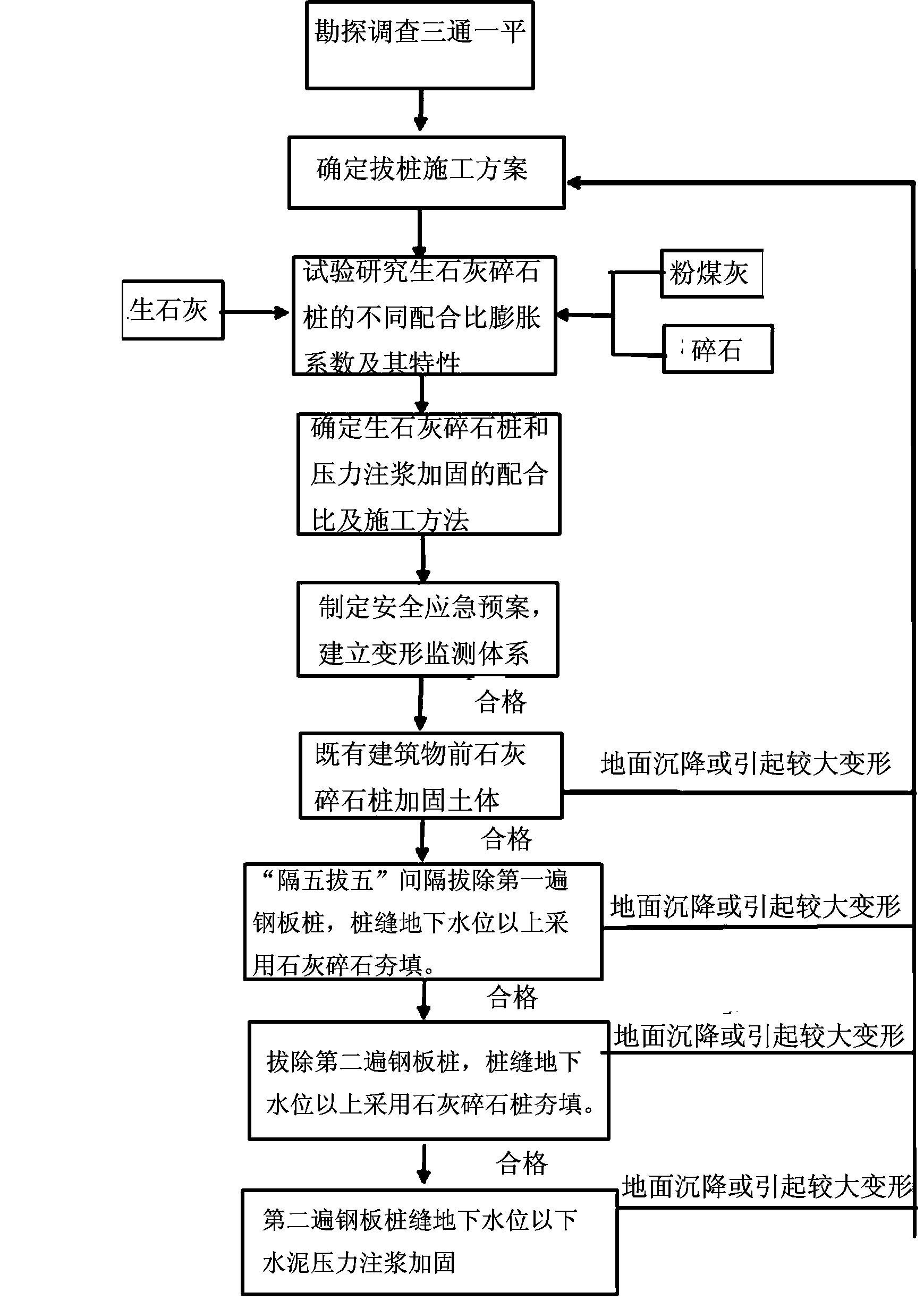

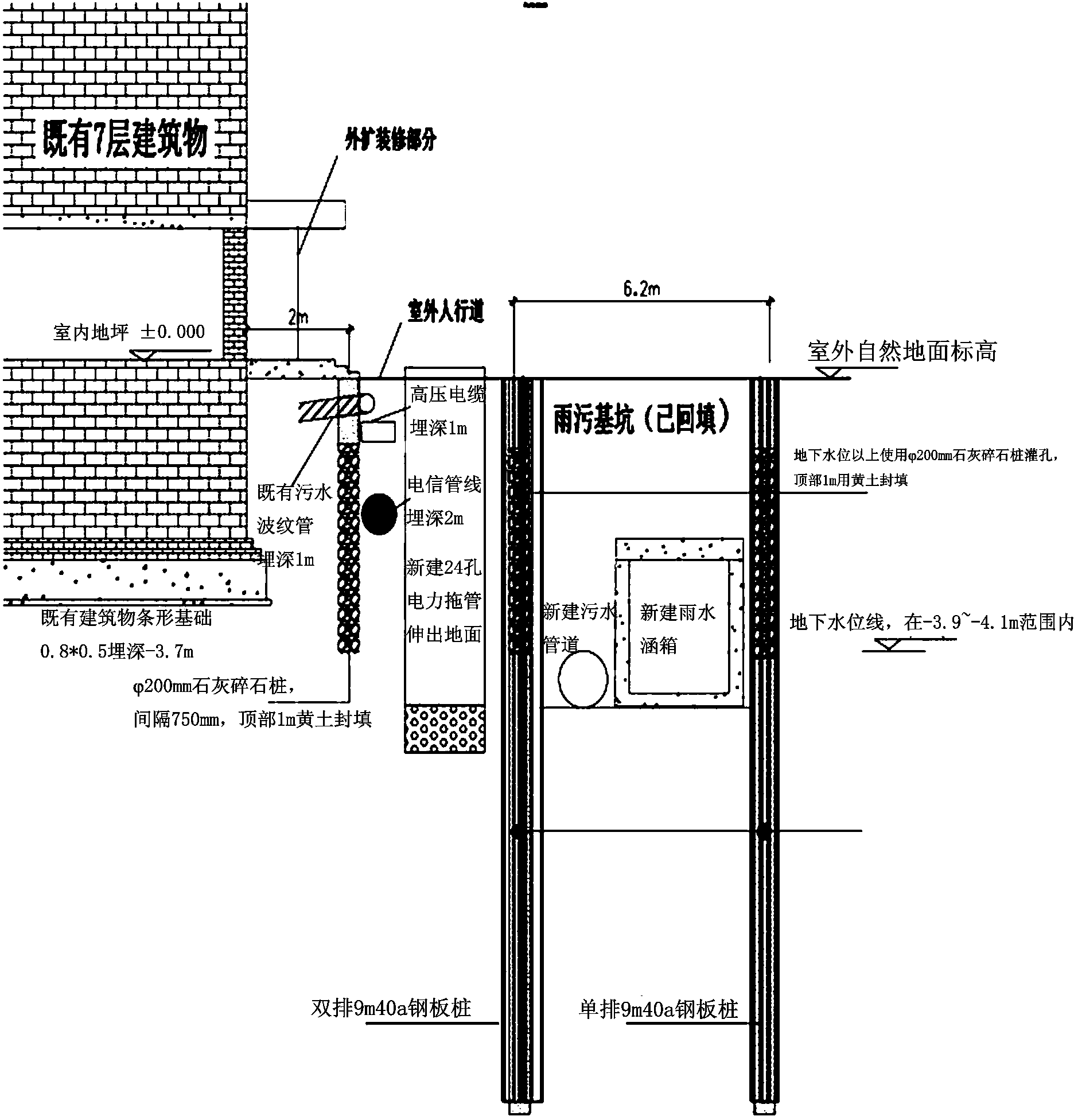

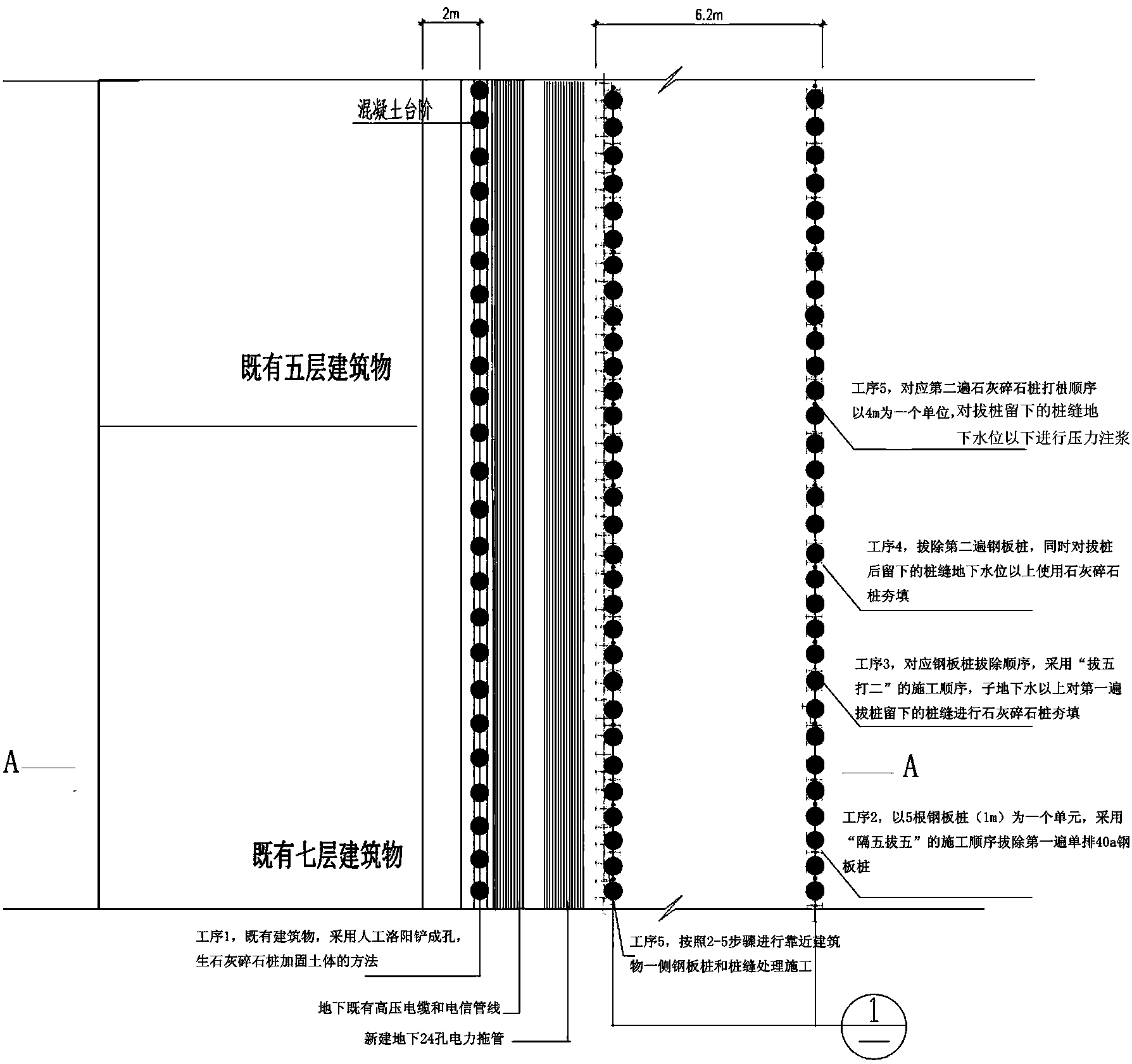

Method used

Image

Examples

Embodiment Construction

[0021] A construction method for removing steel sheet piles adjacent to an existing building, comprising the following steps: ① Remove five steel sheet piles as a unit, and remove one unit at intervals, which is the first step of removal; The construction method of "pulling out five times and hitting two" is carried out by removing the pile gaps left by one time, that is, driving two limestone piles with a diameter of Φ200mm into the pile gaps left after the removal of each steel sheet pile unit, and placing the piles The top of the limestone pile is 1~1.2m (1.0m, 1.1m, 1.2m can be selected) from the ground and sealed with loess; ③ Pull out the remaining steel sheet piles for the second time, The pile gap left by the second pullout is carried out with the construction method of "pulling five times and hitting two", that is, two limestone piles with a diameter of Φ200mm are driven into the pile gap above the groundwater level after each steel sheet pile unit is pulled out. Fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com