High speed railway collapsible loess tunnel foundation base configuration

A technology for collapsible loess and high-speed railways, applied in infrastructure engineering, building structures, roads, etc., can solve the problems of calculation theory, processing methods, construction machinery and construction technology that are difficult to meet requirements, mutual influence and interference, lack of experience and Technical and other issues, to achieve the effect of eliminating loess collapsibility, little impact on stability, and good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

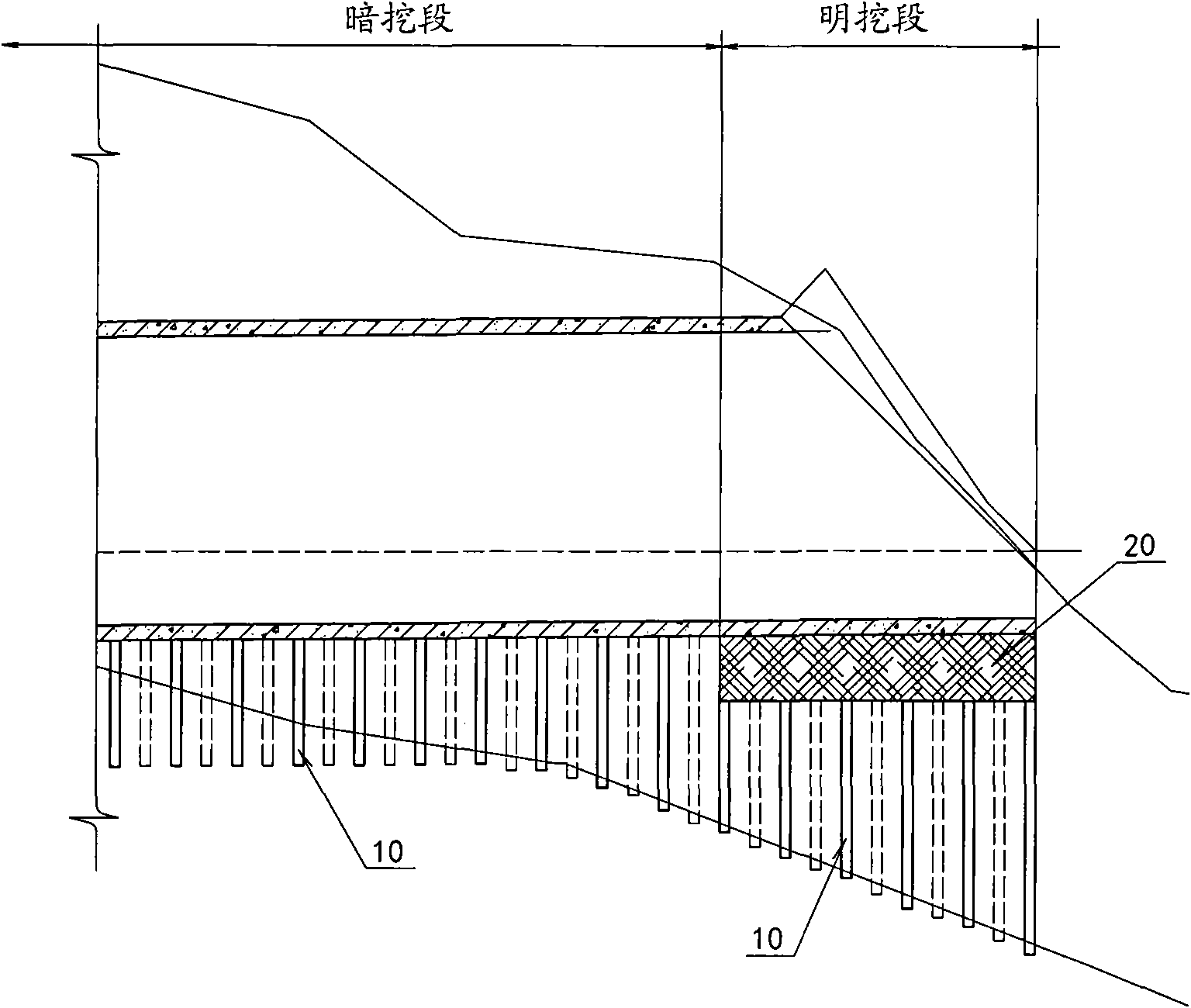

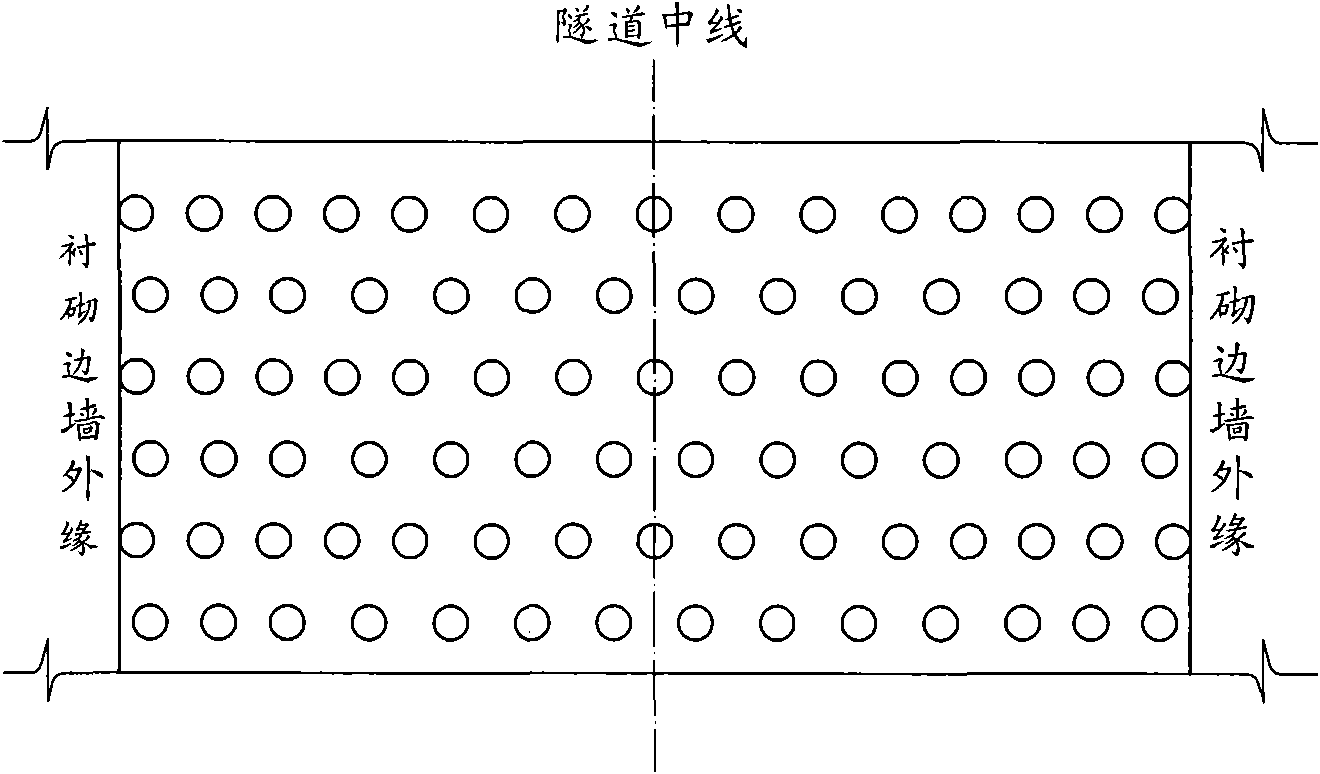

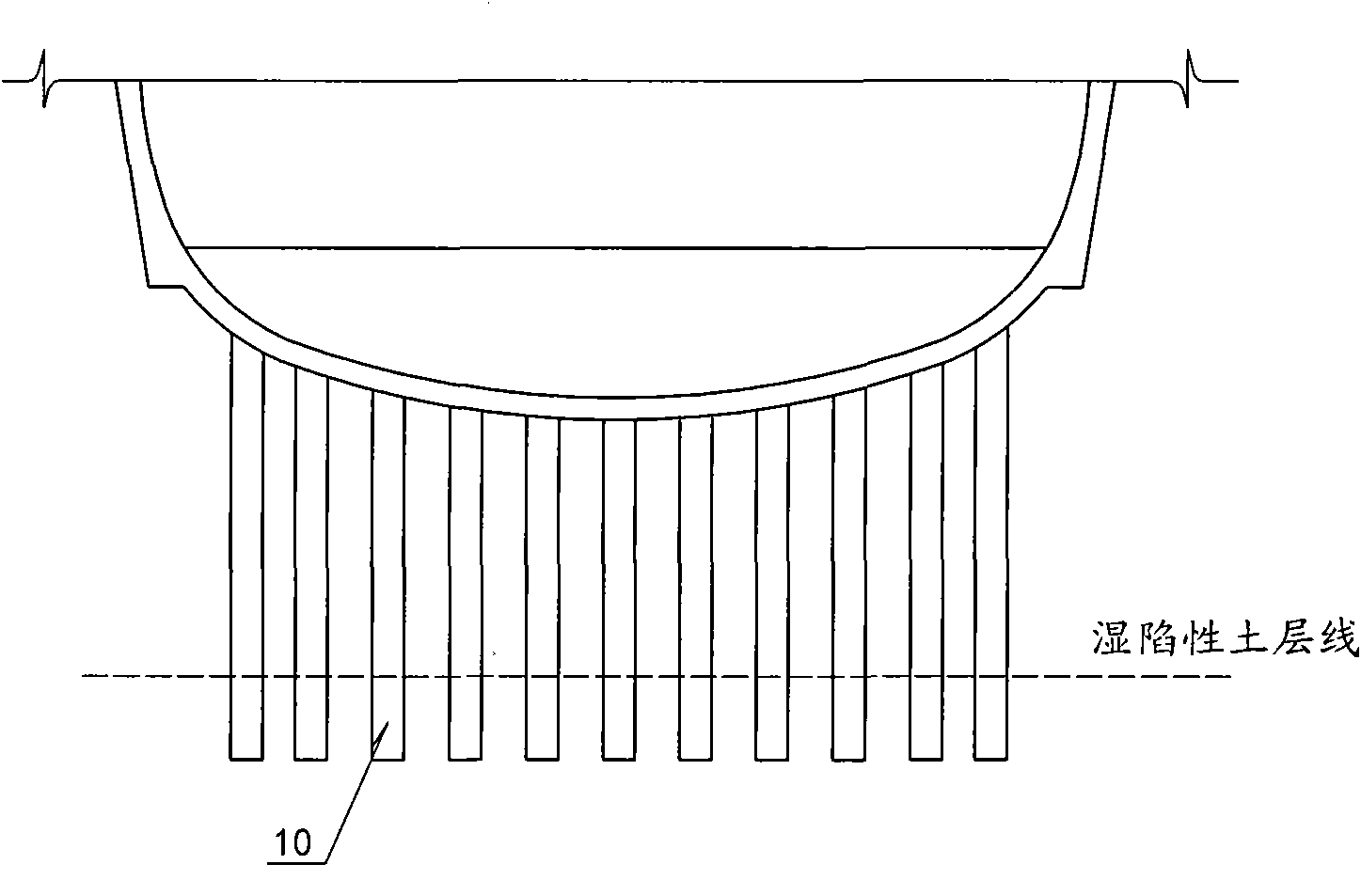

[0016] refer to figure 1 , the high-speed railway collapsible loess tunnel foundation reinforcement structure of the present invention includes the base reinforcement structure of the open excavation section and the base reinforcement structure of the underground excavation section. refer to figure 1 , figure 2 , image 3 and Figure 4 The base reinforcement structure of the open excavation section and the base reinforcement structure of the underground excavation section both include cement-soil compaction piles 10 arranged in rows along the longitudinal and transverse intervals of the foundation, and the lower ends of each compaction pile 10 pass through the collapsible loess line and enter Old loess strata. Since the cement-soil compaction pile 10 laterally compacts the soil around the pile hole in the process of forming a hole and compacting t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com