Construction method for precast pile composite foundation, applied to elimination of loess collapsibility

A construction method and composite foundation technology, applied in foundation structure engineering, sheet pile walls, drilling with vibration, etc., can solve problems affecting construction efficiency and treatment effect, large negative friction resistance around piles, low moisture content of loess, etc., to achieve The reinforcement effect is remarkable, the effect of improving the bearing capacity and accelerating the sinking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Refer to attached figure 1 , figure 2 and image 3 .

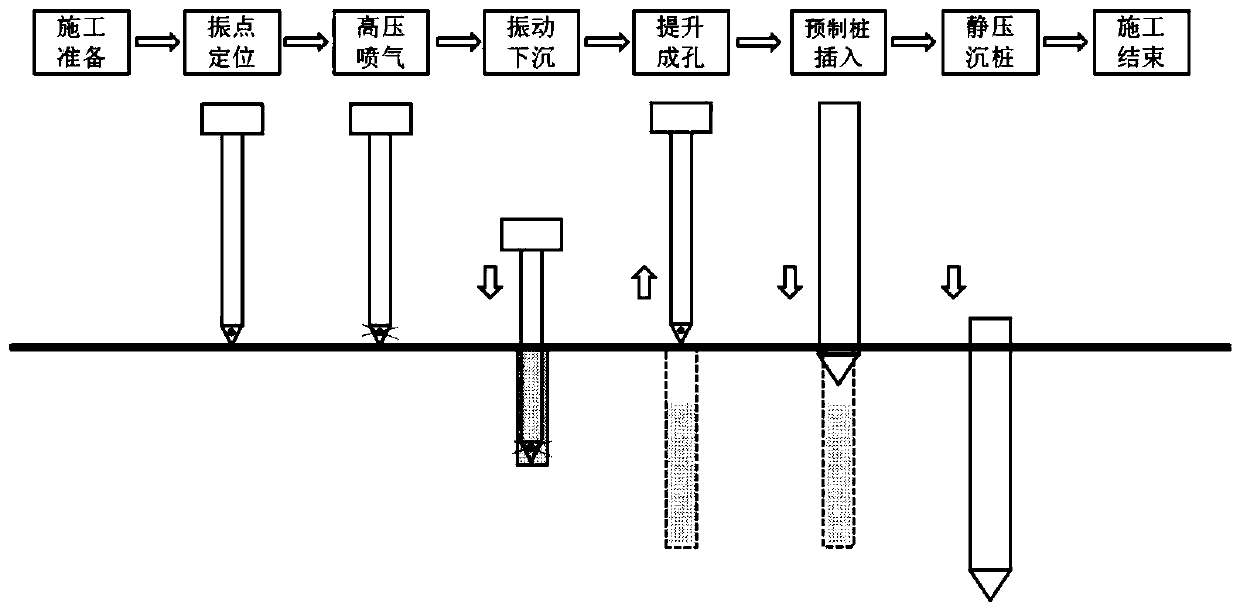

[0036] The construction method of prefabricated pile composite foundation for eliminating the collapsibility of loess comprises the following steps:

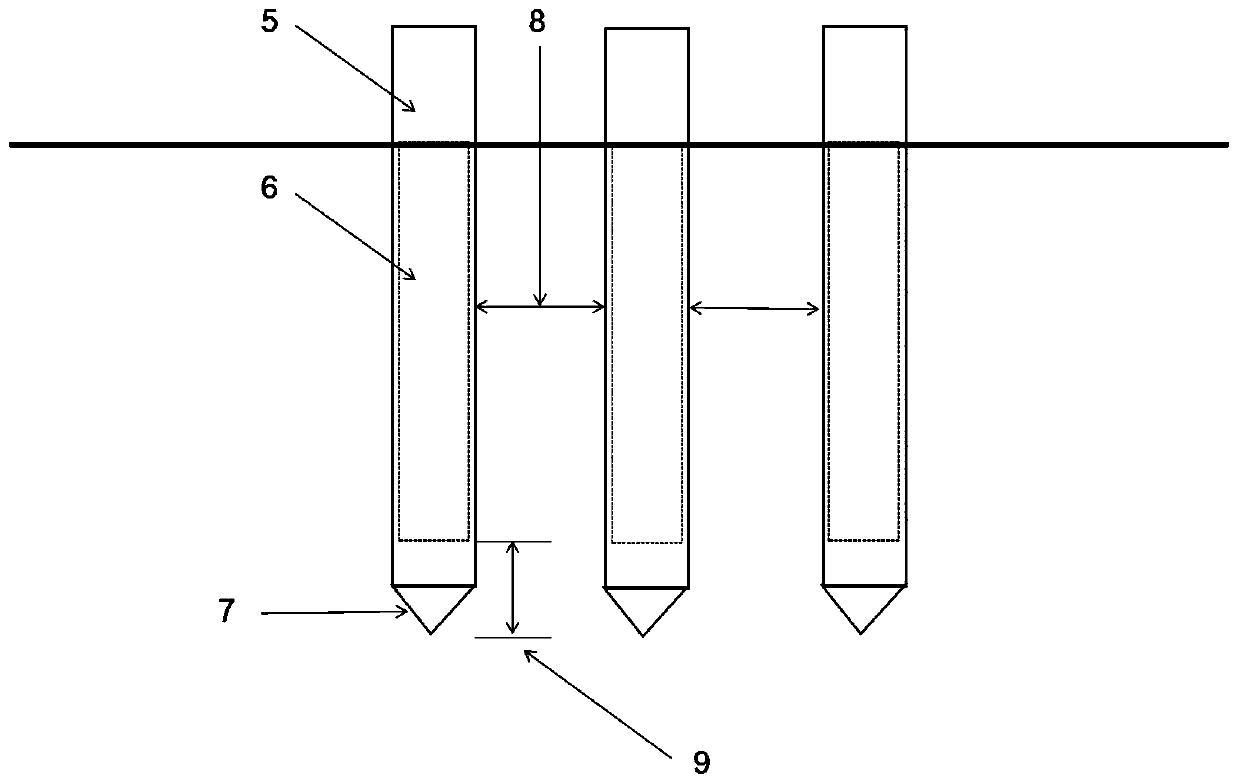

[0037] 1) Level the site before construction, measure and stake out according to the design drawings, mark the position of the vibration points, and the distance between vibration points 8 is determined to be 2.5m according to the design plan.

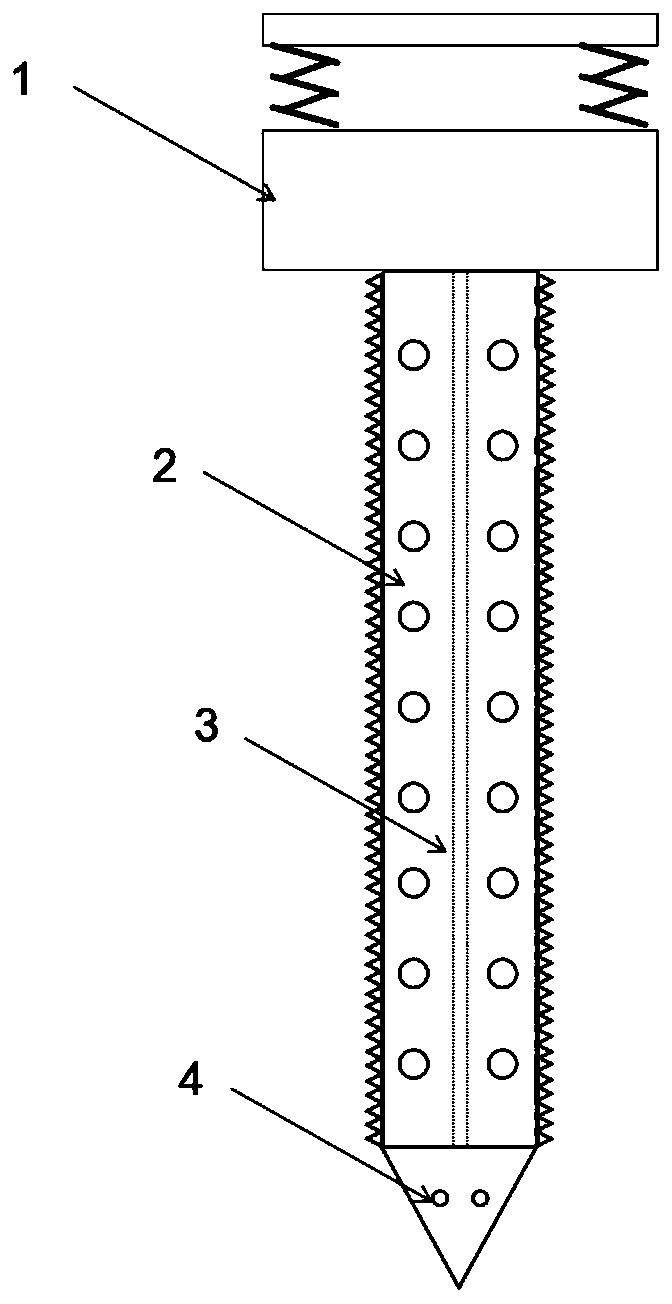

[0038] 2) Vibration point positioning: The crane suspends the special vibrating rod 2 to the designated point and aligns it. Adjust the vibrating rod 2 to be perpendicular to the ground. The verticality deviation of the vibrating rod 2 should not exceed 3%.

[0039] 3) High-pressure air injection: Turn on the air compressor to make the high-pressure air flow along the ventilation pipe 3 inside the vibrating rod 2 to the air injection hole 4 on the drill bit below the vibrating rod 2 . In order to prevent clogging, the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com