Method of treating collapsible loess foundation by two-way spiral drill compaction process

The technology of collapsible loess and two-way spiral is applied in the field of treatment of collapsible loess foundation, which can solve the problems of shallow treatment depth, etc., and achieve the effect of good effect, good economic benefit and reduction of loess collapsibility grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

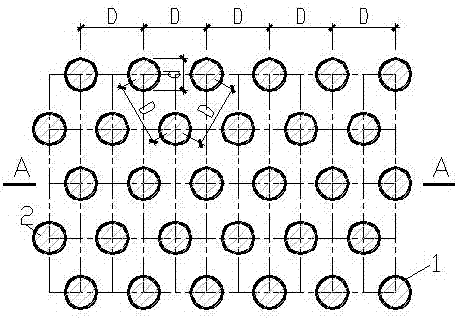

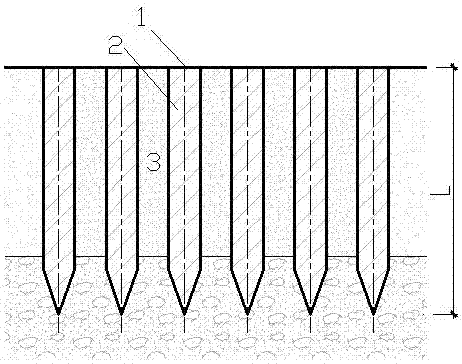

[0021] As shown in the figure, plain soil or lime soil (2) is filled in the hole (1), and the compacted loess foundation (3) is between adjacent holes (1).

[0022] The steps of the construction method are as follows:

[0023] (1) Positioning according to the pile position map to control the position of the pile;

[0024] (2) The two-way helical drill drills in place, and after reaching the design depth, reverse and lift the drill bit until the drilling is completed; the hole diameter d=400-600mm, and the hole spacing D= is controlled at 2d-3.5d.

[0025] The depth L of the borehole is determined according to the thickness of the loess layer and the depth of burial, and the deepest can be processed L=30 meters.

[0026] (3) Fill the hole with plain soil or lime soil (2), lift the slender hammer to do free fall to tamp the plain soil or lime soil until it re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com