Vibration process of eliminating wet foundation falling for CFG pile

A treatment method, the technology of the vibration method, is applied in the direction of sheet pile walls, foundation structure engineering, soil protection, etc., which can solve the problems of uneconomical cost and construction period, high cost of materials, and small pile spacing, etc., to improve the bearing capacity of the foundation, Eliminates collapsibility and saves costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

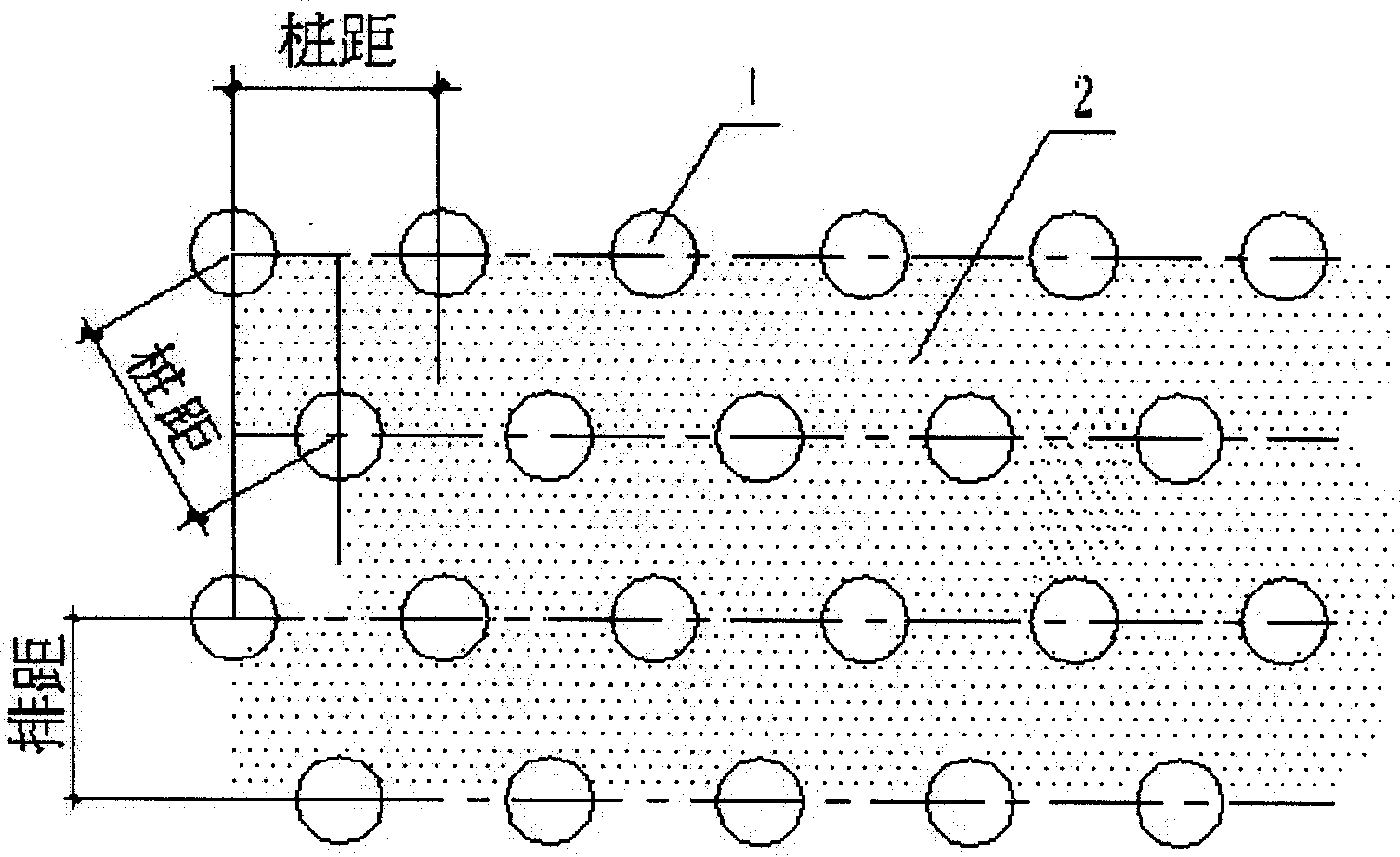

[0011] Embodiment of the present invention: on the collapsible loess foundation 2 of 29.45m×120m, the composite foundation is made by using the vibration method CFG pile 1 . The diameter of the vibration method CFG pile 1 is 400mm, the pile positions are arranged in an equilateral triangle, and the pile distance is 1.2m. The vibration sinking tube grouting pile construction technology is used for construction. The pile ends are placed on the top of the pebble layer, and the pile body compaction coefficient is 0.97. After the construction is completed, the bearing capacity of the composite foundation will reach the design value of 200Kpa, and the collapsibility of the foundation soil will be completely eliminated. Compared with the previous method of "strong compaction first, then piles", the construction period is shortened by 35%, the investment is saved by 40%, and the economic benefits are remarkable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com