Collapsible loess foundation treatment method

A technology for collapsible loess and a treatment method, which is applied in the field of civil engineering and can solve the problems of affecting soil water immersion and consolidation effect, accurate observation of collapsible settlement, difficulty in subsequent construction, and evaporation time after passing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

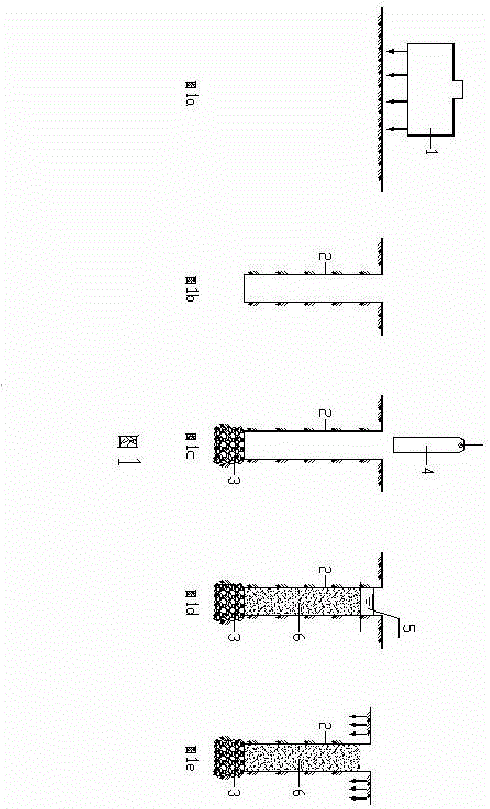

[0048] The process diagram of the treatment method of the 1st kind of collapsible loess foundation as an embodiment of the present invention, it comprises the following steps, at first, as figure 1 As shown in a, use the dynamic compaction method to tamp the surface soil of the foundation with the rammer 1, and then, as figure 1 As shown in b, the hole is formed to a certain depth to form the perfusion hole 2, and then, as figure 1 As shown in c, through the filling hole 2, fill the filling material 3 at the bottom of the filling hole 2, and tamp and compact it with the slender hammer 4, and then, as figure 1 As shown in d, pour water 5 into the pouring hole 2 and fill sand and gravel 6 until a certain distance from the foundation surface, finally, as figure 1 As shown in e, the foundation soil gradually produces self-weight collapsibility after soaking in water until the collapsible deformation is stable.

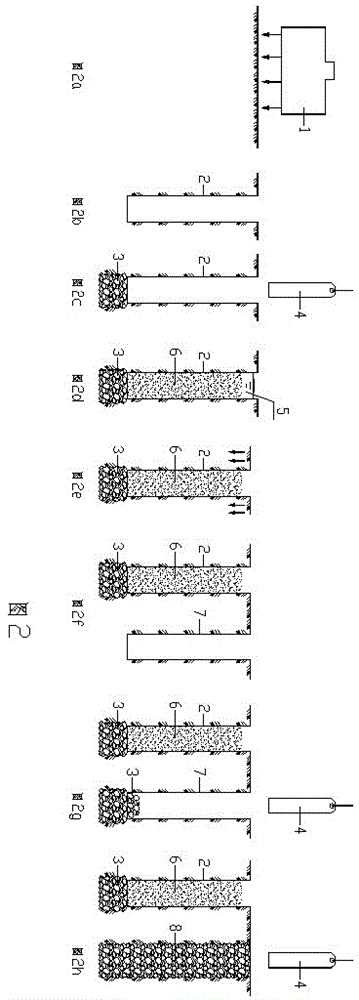

[0049] As another embodiment of the present invention, the 2nd kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com