Dynamic compaction reinforcing method for improving stability of cast-in-place pile collapse hole

A technology of stability and cast-in-place piles, applied in the direction of instruments, geometric CAD, calculation, etc., can solve problems such as boundary conditions, constitutive relations are relatively strict, it is not easy to apply to engineering practice, and no prevention and control measures are proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

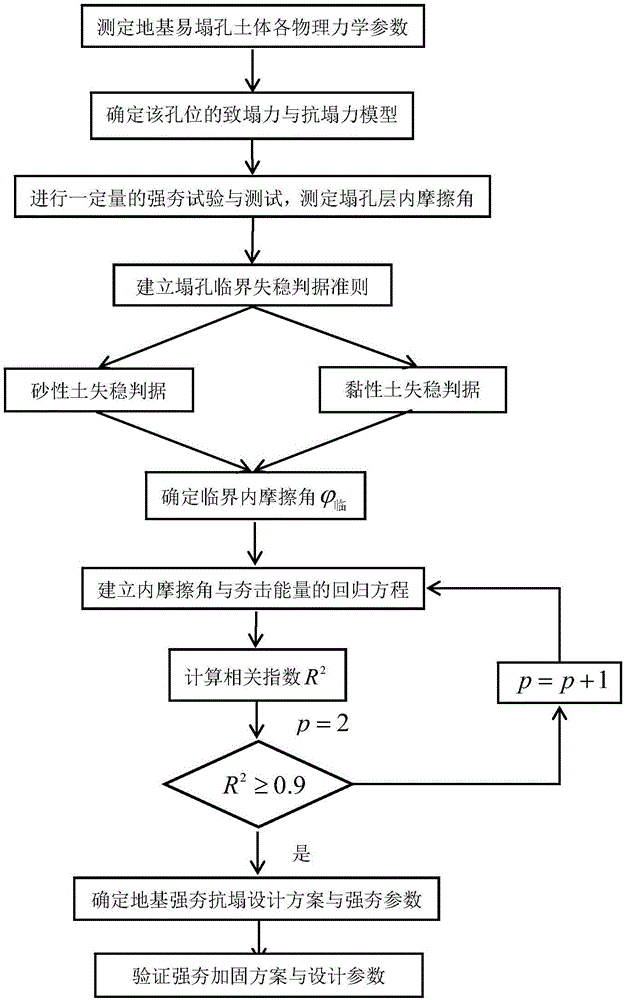

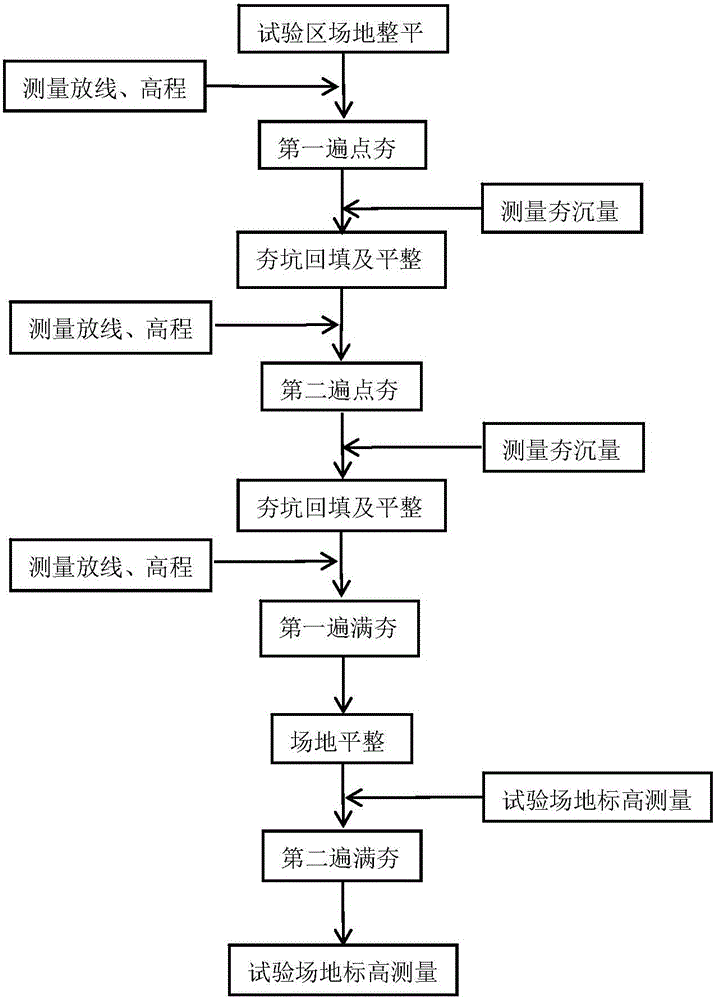

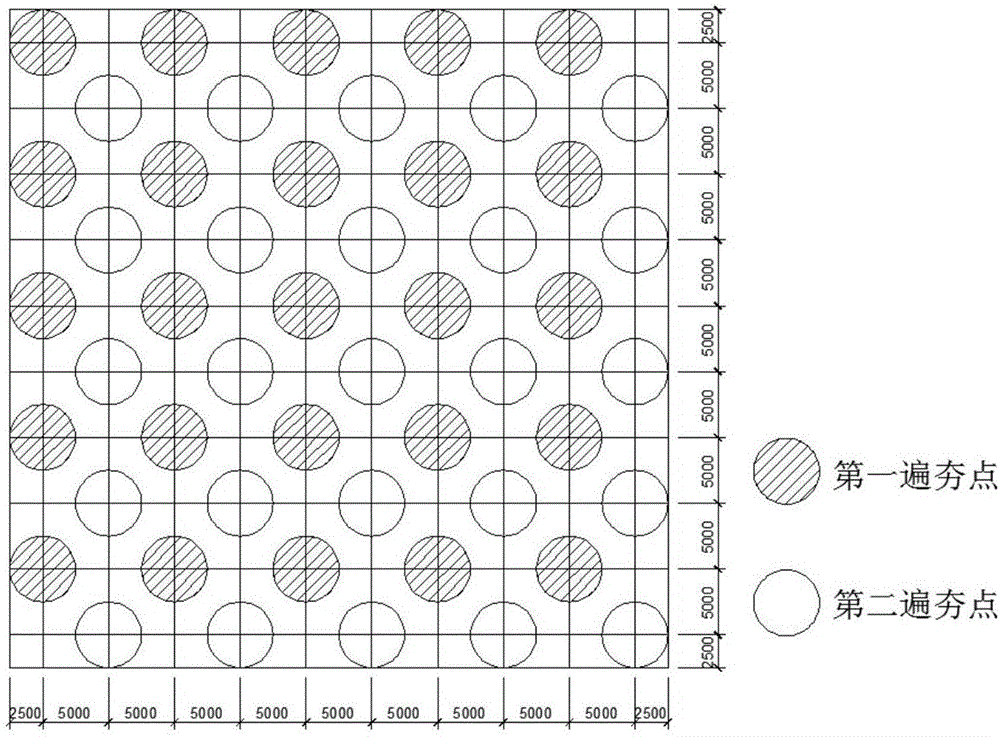

Method used

Image

Examples

Embodiment Construction

[0188] In order to clearly illustrate the implementation of the present invention, the following takes a heavy oil processing project cast-in-place pile project as an example to analyze and evaluate the hole collapse problem of bored cast-in-place piles in this area.

[0189] All important devices and pipe galleries in the project area are based on pile foundations, and there are about 2,000 cast-in-situ piles. However, due to the special geological conditions of the loose ground in the foundation of the project area, during the construction of bored piles, the sand layer often has serious hole collapse problems. A certain amount of dynamic tamping experiments and tests were carried out on the bored pile engineering site, and the dynamic tamping scheme and dynamic tamping parameters were determined. Based on the values, the design scheme and parameters of dynamic tamping anti-collapse of the foundation are determined.

[0190] Specific steps are as follows:

[0191] Step 1: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com