Hinge points-variable combined type multi-functional crawler crane

A multifunctional crawler and crawler crane technology, which is applied to cranes, crawler vehicles, motor vehicles, etc., can solve the problems of high use and maintenance costs, increased manufacturing costs and management costs, and the prohibition of lifting operations or lifting climbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

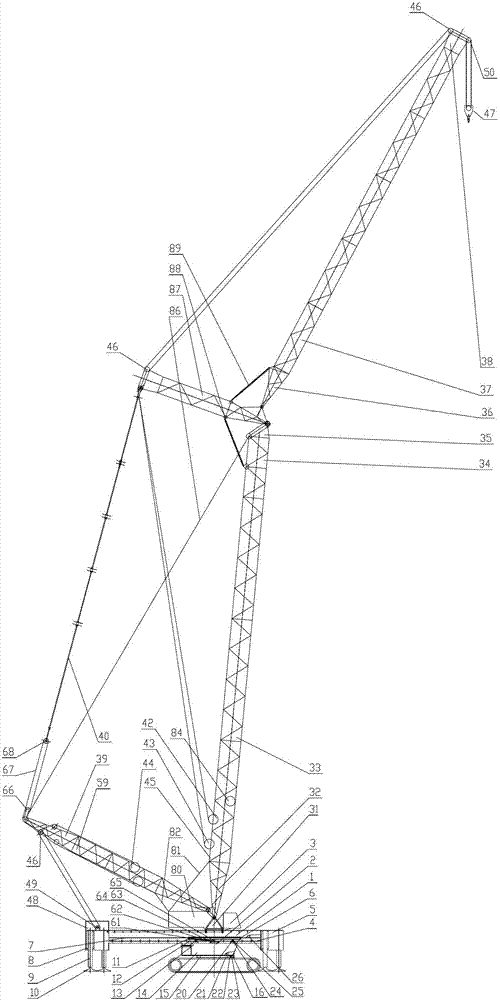

[0030] Example 1, such as figure 1 As shown in the figure, a humanoid tower stacking operation condition of a combined multifunctional crawler crane with variable hinge points is shown. The unit 2 and the multi-hinge connection unit 1 are connected by hinge pins, and the relative positions of the hinges are changed according to actual needs during the operation.

[0031] The multi-hinge connection unit 1 includes a multi-hinge main beam 4, a leg 5, a sliding bracket 6, and a power and control device 26; the outrigger 5 and the multi-hinge main beam 4 are hinged by telescopic sliding or rotating The sliding bracket 6 is connected with the load-bearing slideway 7 in the multi-hinged main beam 4 by sliding or rolling, and the power and operating device 26 is connected with the multi-hinged main beam 4 by hinges or bolts.

[0032] Described support leg 5 comprises movable support leg 8, vertical telescopic oil cylinder 9, support foot 10, and movable support leg 8 is fixedly con...

Embodiment 2

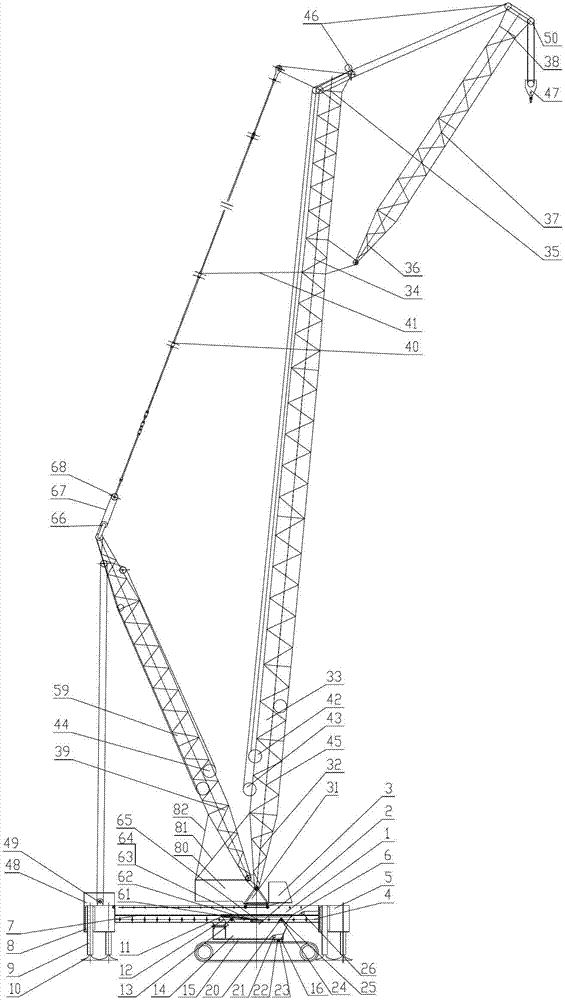

[0038] Example 2, such as figure 2 As shown, a T-shaped tower stacking operation condition of a combined multifunctional crawler crane with variable hinge points, the T-shaped tower stacking operation condition of the crawler crane includes a multi-hinge point connection unit 1, a walking slewing unit 2, and an operating unit 3; The walking turning unit 2 is connected with the multi-hinge point connection unit 1 by hinge pins, and the relative positions of the hinges are changed according to actual needs during the operation.

[0039] The parts and work included in the multi-hinge connection unit 1 and the walking and turning unit 2 are basically the same as those in the first embodiment.

[0040] The T-shaped stacking operation working unit 3 includes a connecting seat 31, a main boom root section 32, a main boom standard section 33, a transition section 34, a main boom head 35, a tower boom root section 36, a tower boom standard section 37, Tower arm head 38, main mast 39...

Embodiment 3

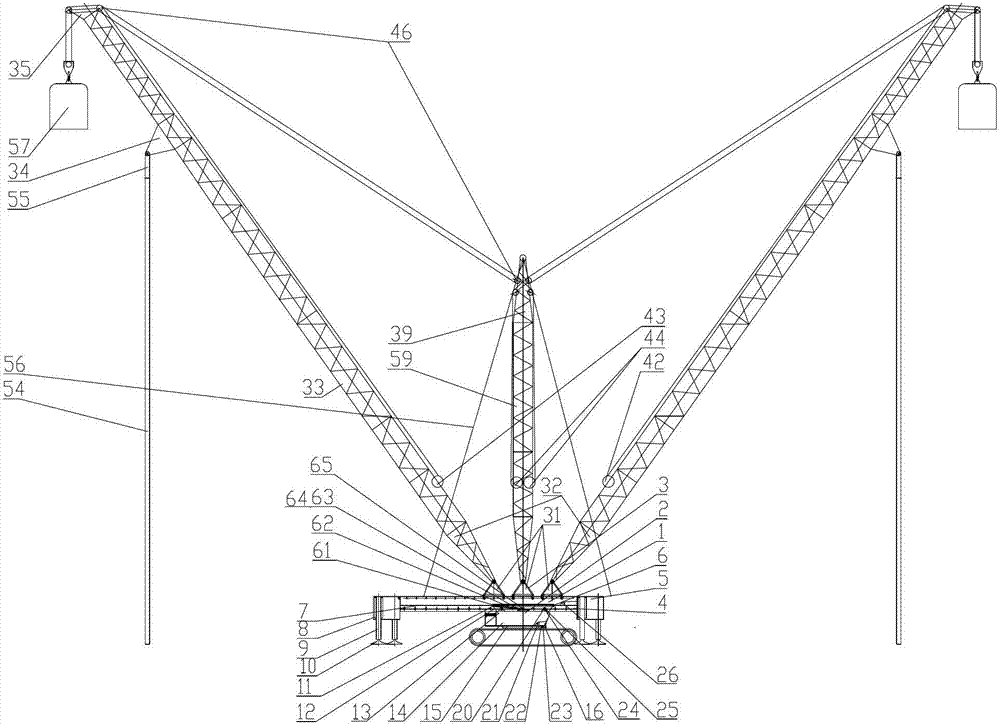

[0041] Example 3, such as image 3 As shown, a dual-hammer dynamic compaction working condition of a multifunctional crawler crane combined with variable hinge points, said crawler crane double-hammer dynamic compaction working condition includes a multi-hinge point connection unit 1 , a walking slewing unit 2 , and an operating unit 3 . The walking turning unit 2 is connected with the multi-hinge point connection unit 1 by hinge pins, and the relative positions of the hinges are changed according to actual needs during the operation.

[0042] The parts and work included in the multi-hinge connection unit 1 and the walking and turning unit 2 are basically the same as those in the first embodiment.

[0043] The working unit 3 of the double-hammer dynamic compaction operation includes 3 connecting seats 31, 2 main boom root sections 32, 2 main boom standard sections 33, 2 transition sections 34, 2 main boom heads 35, a main mast 39. Main hoist 42, auxiliary hoist 43, 2 luffing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com