Construction method for treating costal backfill ultrathick gravel soil foundation by 25000 KN.m dynamic compaction

A construction method and soil foundation technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems that the treatment cannot be reached, and the treatment depth is limited to 10-12 meters, etc., and achieve short construction period, obvious treatment effect, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

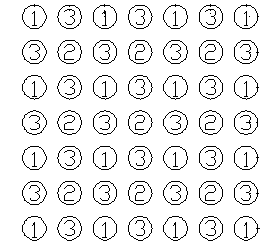

Image

Examples

Embodiment

[0027] During the construction, the test rammer is carried out first, and the energy level is increased step by step from the low energy level to the specified energy level. The height of the first blow is 10 meters, the height of the second blow is 15 meters, the height of the third blow is 20 meters, and the height of the fourth blow is 25 meters.

[0028] The specific construction steps are as follows:

[0029] 1) Construction preparation:

[0030] Determine the construction of the ramming surface, and level the site to the elevation of the ramming surface.

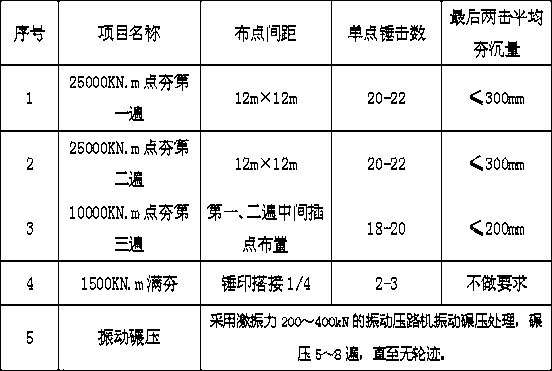

[0031] 2) The first pass of main tamp energy level construction:

[0032] Release the first main tamp energy level tamping point on the ramming surface, and carry out the main tamping point dynamic tamping with an energy level of 25000KN. Measure the elevation of the site with the square grid, and calculate the ramming settlement of the first pass of the main ramming site.

[0033] 3) The second energy-level constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com