Semi-module test box for dynamic compaction reinforced foundation model test

A technology of foundation model and model box, which is applied in the field of geotechnical engineering, can solve the problems that restrict the development and improvement of dynamic compaction method, the difficulty of indoor model test of dynamic compaction method, and the lack of theoretical basis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

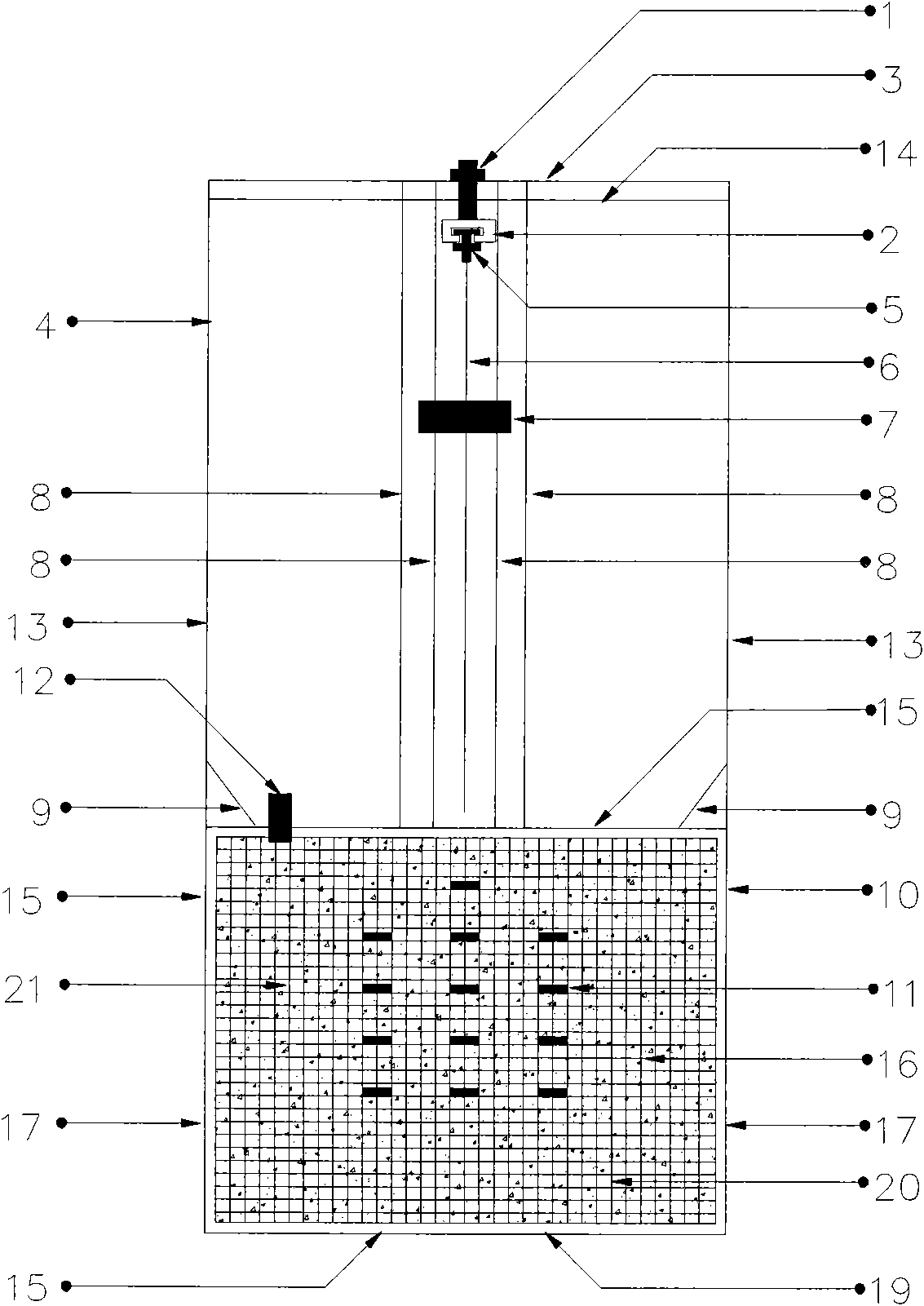

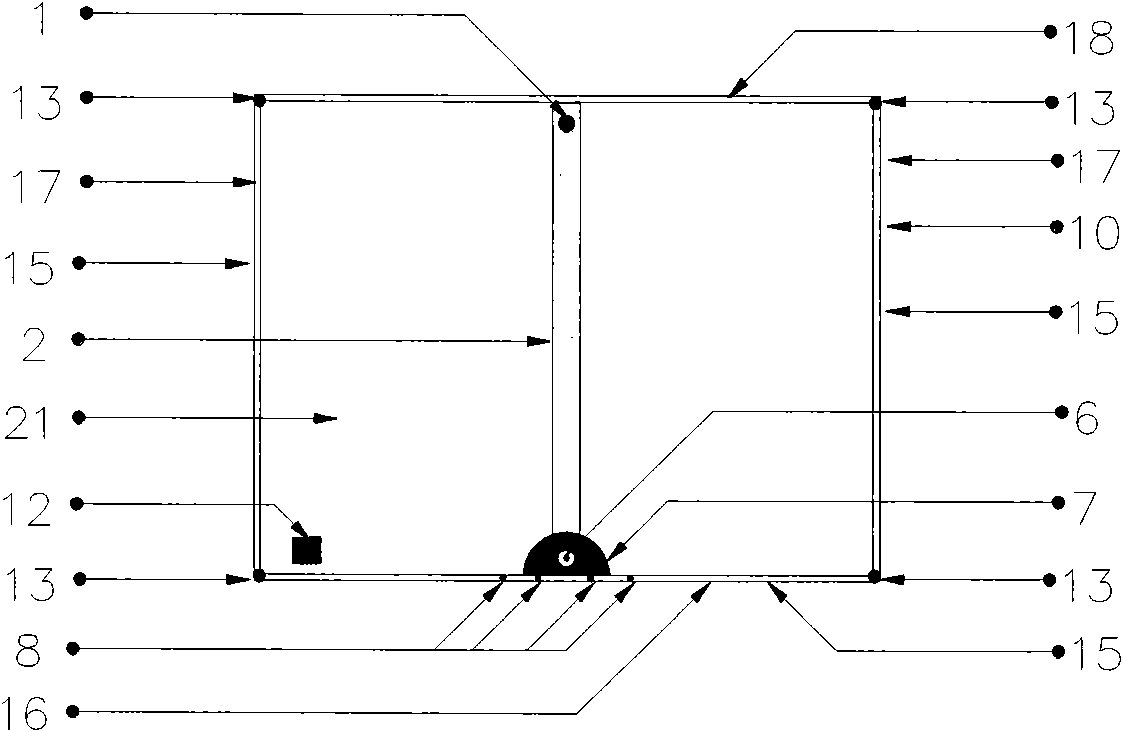

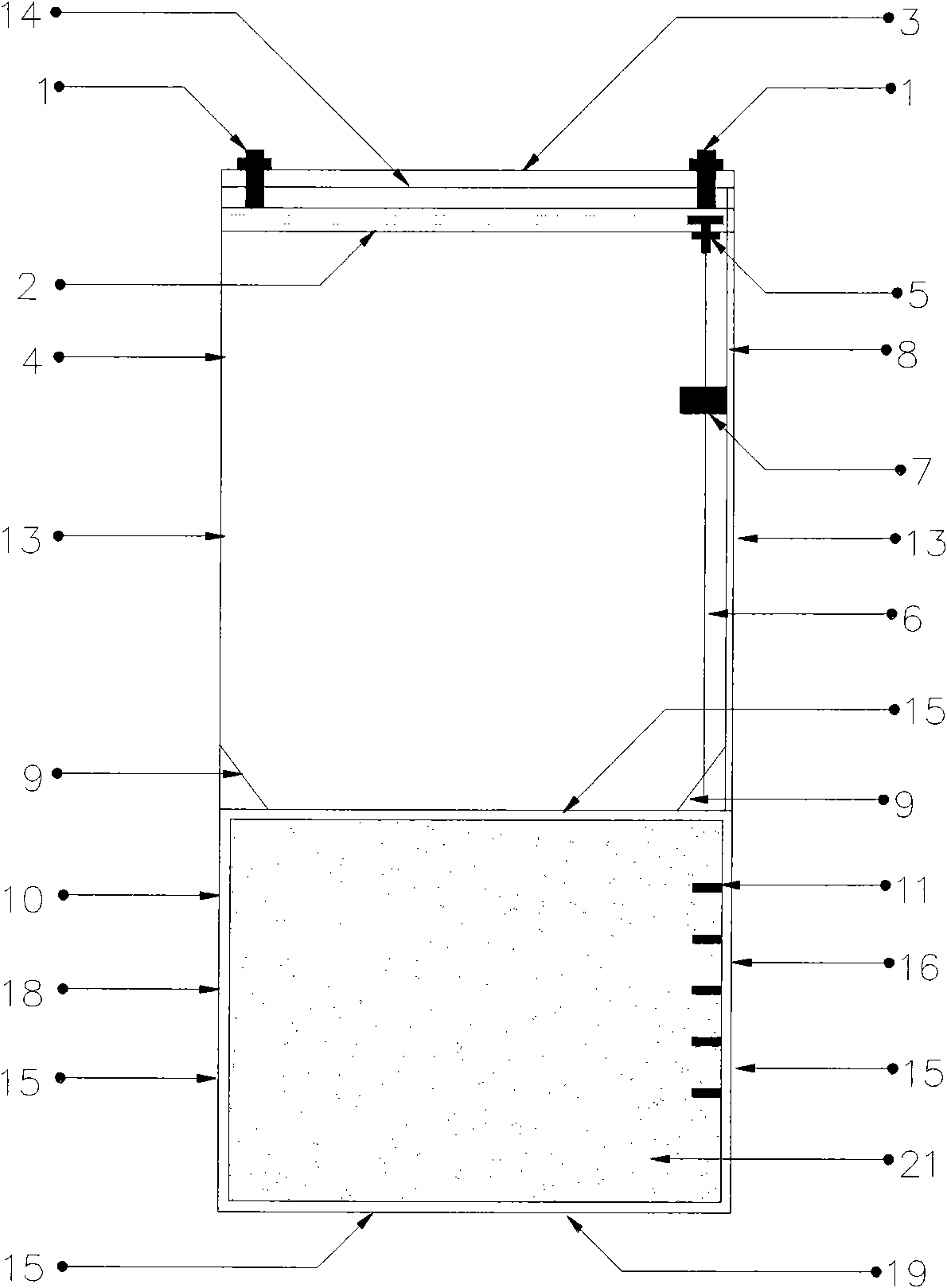

[0019] Embodiment 1, the length of the angle steel 15 in the model box 10 is 1000 mm, the width is 25 mm, and the thickness is 4 mm. The side panel 17 of model box 10, back panel 18 and base plate 19 are the planks of thickness 30 millimeters, and the front of model box 10 is the plexiglass plate 16 of thickness 10 millimeters, and the length and the width of each panel, base plate are 1000 millimeters, The surroundings of the model box frame are embedded in the angle steel 15, and are connected with the angle steel 15 by bolts. Graduation lines 20 are drawn on the plexiglass plate 16, and each grid size of the graduation lines is 10 mm×10 mm. Support 4 is welded by 4 vertical bars 13 and 4 cross bars 14, and vertical bars 13 and cross bars 14 are all 1000 millimeters in length, 20 millimeters in outer diameter, the steel pipe of wall thickness 2 millimeters. The four vertical rods 13 in the bracket 4 are located above the model box 10, connected with the angle steel 15 posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com