Vibration isolation plate device in soil matrix treatment engineering and construction technology thereof

A vibration isolation and soil foundation technology, which is applied in basic structure engineering, protection devices, buildings, etc., can solve the problems of uneconomical, large amount of earthwork, difficult to master the ratio of poles, etc., so as to ensure the vibration isolation effect and strengthen the vibration isolation effect. , the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 (Shallow Layer Vibration Isolation):

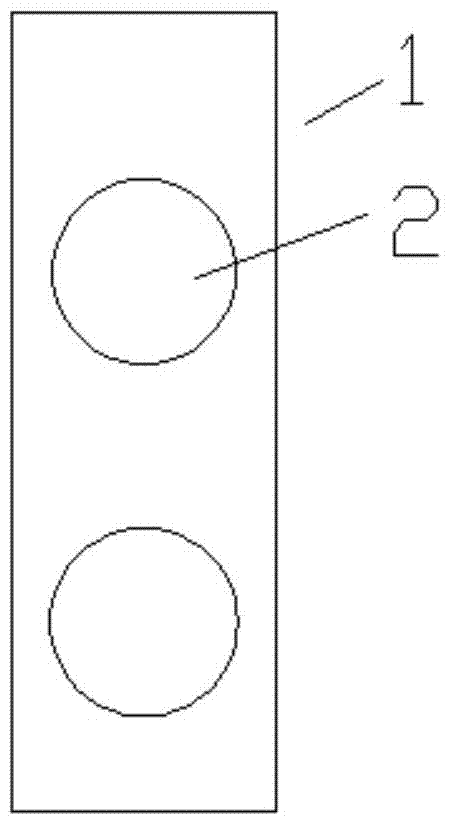

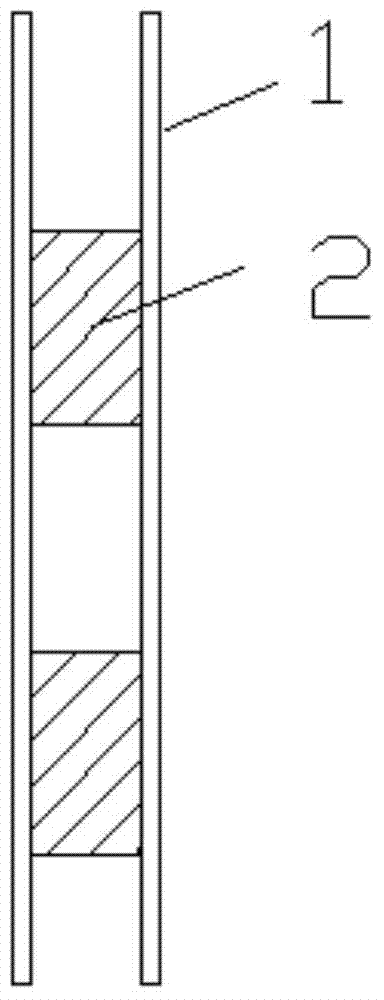

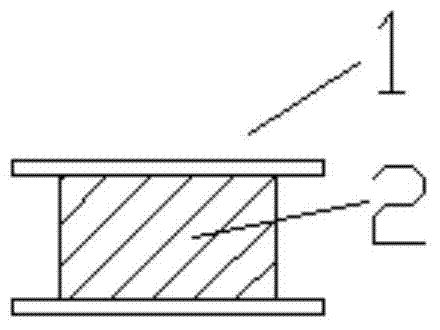

[0064] Such as Figure 1~5 As shown, a new type of vibration isolation board includes a vibration isolation single board 1 and a vibration isolation module 2 arranged between two vibration isolation boards. Here, an inflatable airbag is taken as an example. The components of the vibration isolation veneer 1 are polymers such as polypropylene and polyvinyl chloride, and PVC building formwork with mature production technology can be selected. Inflatable air bag 2 can be selected the rubber tire of suitable size for use, also can design voluntarily according to actual conditions. In addition, by connecting an inflation channel of a certain length to the airbag, it is convenient to adjust the air pressure inside the airbag at any time, which is beneficial to the installation and removal of the vibration isolation plate.

[0065] Horizontally, corresponding vibration isolation modules are arranged at a certain distance betwe...

Embodiment 2

[0076] Example 2 (deep vibration isolation):

[0077] As shown in Figures 6 to 16, a new type of vibration isolation board includes a vibration isolation single board 1 and a vibration isolation module 2 arranged between two vibration isolation boards. Here, an inflatable airbag is taken as an example. The composition of the vibration isolation veneer 1 is high carbon steel. Inflatable air bag 2 can be selected the rubber tire of suitable size for use, also can design voluntarily according to actual conditions. In addition, by connecting an inflation channel of a certain length to the airbag, it is convenient to adjust the air pressure inside the airbag at any time, which is beneficial to the installation and removal of the vibration isolation plate. Due to the large reinforcement depth, the bolts are spliced up and down in the vertical direction. The bottom of the vibration isolation unit located in the lowest layer has a pointed cone structure, which is convenient for co...

Embodiment 3

[0092] Different from Embodiment 1, the vibration isolation module 2 is a compression spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com