Backlight module and liquid crystal display device using same

A technology for liquid crystal display devices and backlight modules, which is applied in optics, nonlinear optics, instruments, etc., and can solve problems such as separation of reflective sheets, failure of upper bumps 11 to support reflective sheets, structural damage of upper bumps 11, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

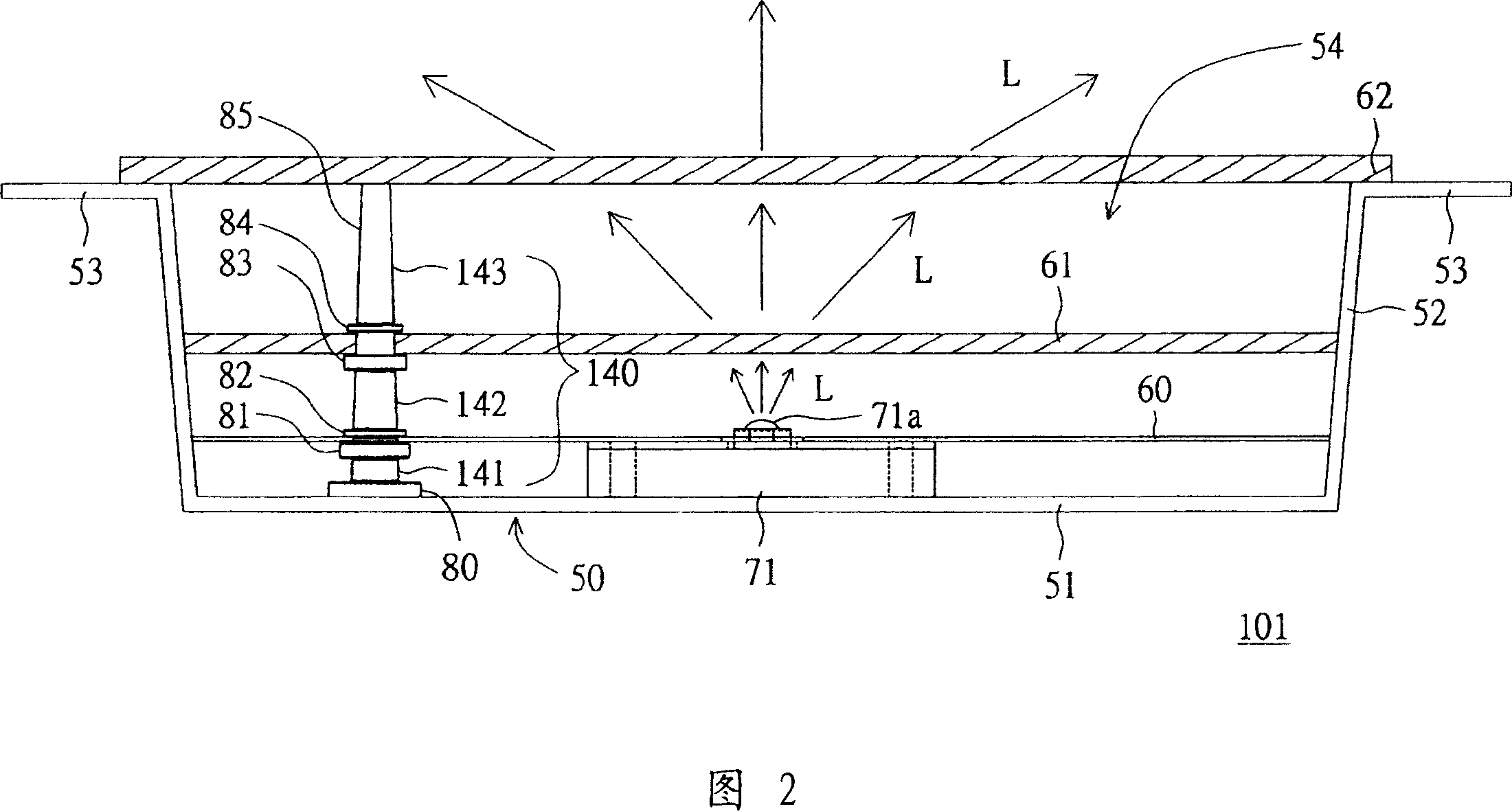

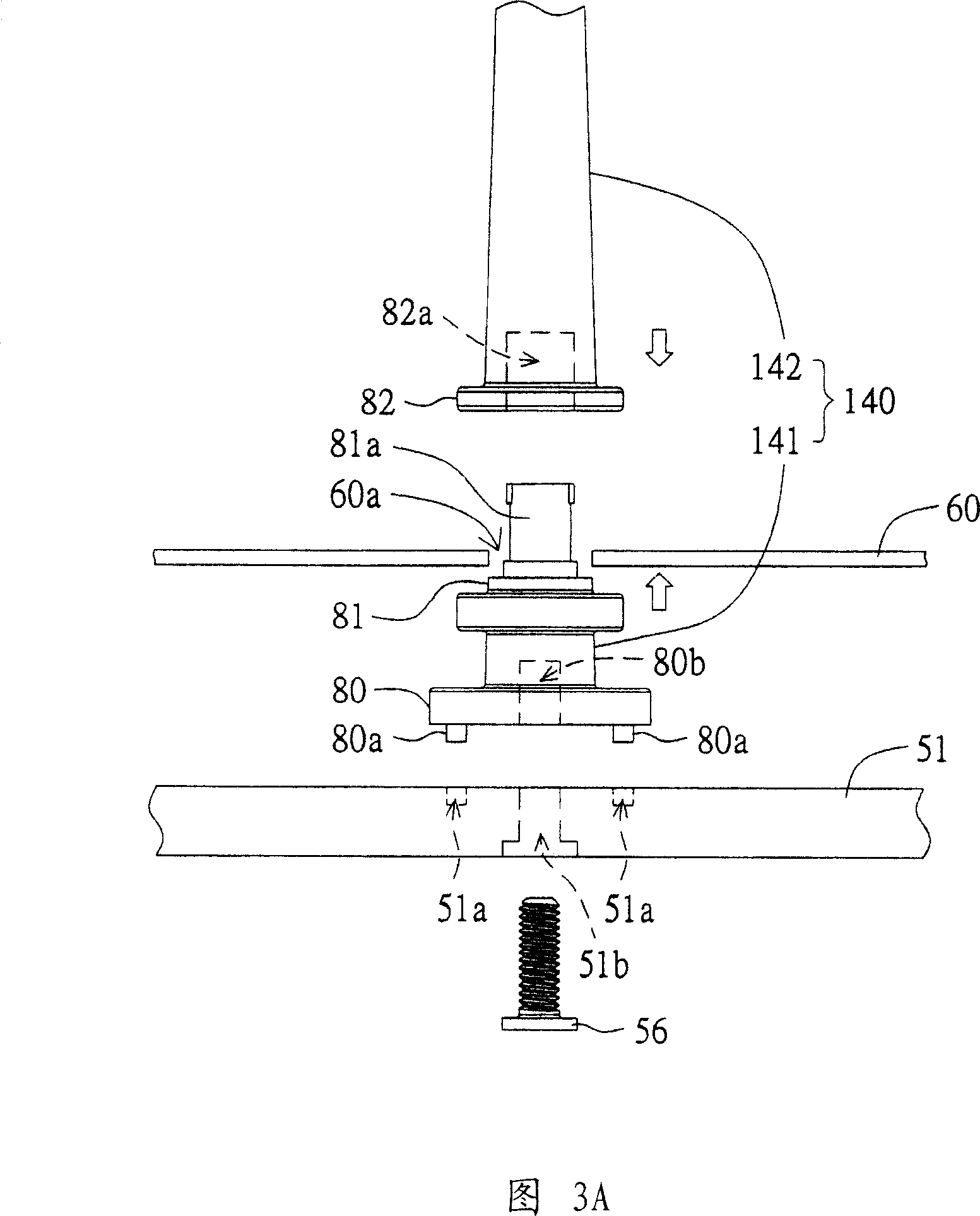

[0072] Please refer to FIG. 2 , which shows a schematic diagram of a partial structure of a backlight module according to Embodiment 1 of the present invention. The backlight module 101 of this embodiment adopts a supporting mechanism 140 to support a first diffusion sheet 61 in the backlight module 101 . In FIG. 2 , the backlight module 101 includes a light source, a frame 50 , a first diffusion sheet 61 and a second diffusion sheet 62 . In this embodiment, the light source is illustrated by taking a light emitting diode module (LED module) 71 as an example. The LED module 71 provides a point light source to emit a light L. As shown in FIG. The frame 50 includes a bottom panel 51 and a side panel 52 . The bottom plate 51 and the side plate 52 define an accommodating space 54 . The LED module 71 is disposed in the accommodating space 54 . The first diffusion sheet 61 is disposed in the accommodating space 54 and above the LED module 71 . The second diffusing sheet 62 is d...

Embodiment 2

[0087] Please refer to FIG. 4 , which shows a schematic diagram of a partial structure of a backlight module according to Embodiment 2 of the present invention. The difference between the backlight module 102 of the present embodiment and the backlight module 101 of the first embodiment lies in the structure of the support structure 240, the arrangement of the optical film 63 and the second diffusion sheet 62, as for the rest of the same components continue to use the reference numerals, and will not repeat them.

[0088] Besides the first bracket 241 , the second bracket 242 and the third bracket 243 , the supporting structure 240 further includes a fourth bracket 244 . The fourth bracket 244 has a sixth clamping end 86 and a seventh clamping end 87 . The fifth clamping end 85 is movably coupled to the sixth clamping end 86 to clamp the second diffusion sheet 62 above the first diffusion sheet 61 .

[0089] The backlight module 102 also includes an optical film 63, which is...

Embodiment 3

[0092] Please refer to FIG. 5 , which shows a schematic diagram of a partial structure of a backlight module according to Embodiment 3 of the present invention. The difference between the backlight module 102 of this embodiment and the backlight module 101 of Embodiment 1 lies in the structure of the reflection sheet 60, the light source, the supporting structure 340 and the arrangement of the first diffusion sheet 61. , and will not repeat them.

[0093] In this embodiment, the reflection sheet 60 is disposed on the bottom plate 51 and the side plate 52 . The light source is a cold cathode fluorescent lamp (cold cathode fluorescent lamp, CCFL) 72 as an example for illustration, and is disposed between the first diffusion sheet 61 and the reflection sheet 60 .

[0094] In this embodiment, the supporting structure 340 includes a first bracket 341 and a second bracket 342 . The first bracket 341 has a bottom end 80 and a first clamping end 81 . The bottom end 80 is not only u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com