Capillary structure of heat plate

a technology of capillaries and heat plates, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of often large amount of heat generated by electronic devices, and achieve the effects of improving the temperature reduction efficiency of the heat plate, enhancing the uniformity of distribution of the working fluid, and increasing the diffusion efficiency of vapor of the working fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

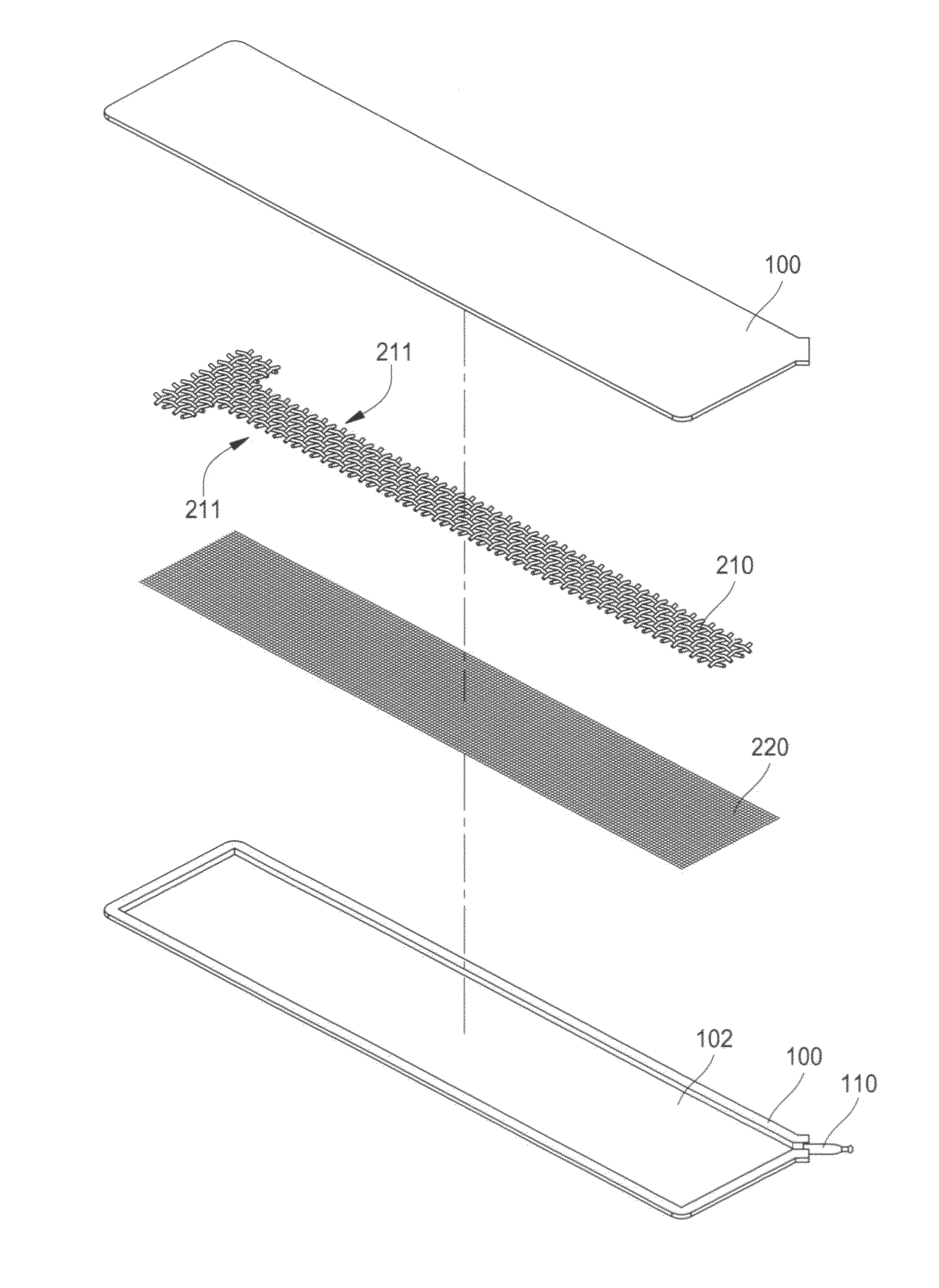

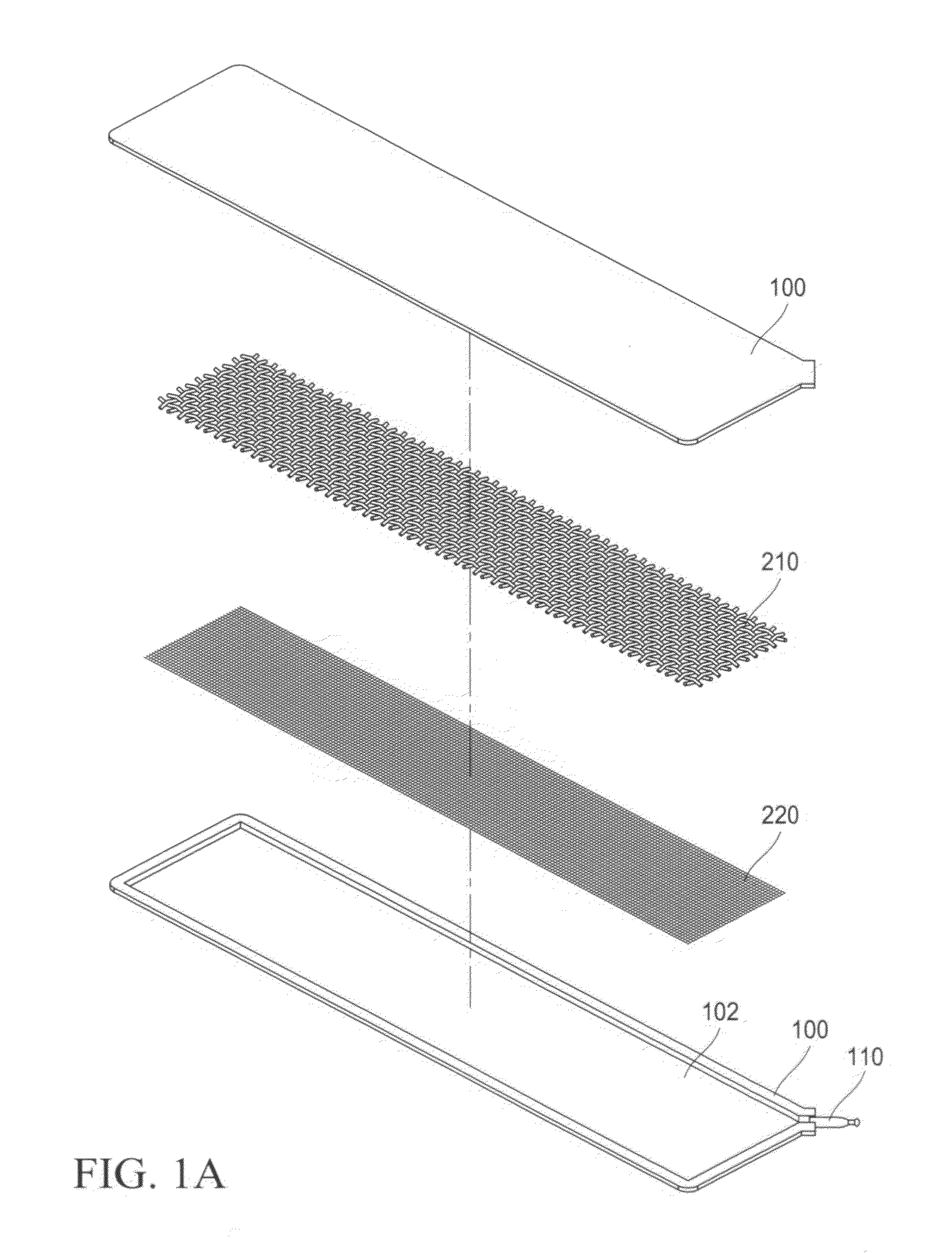

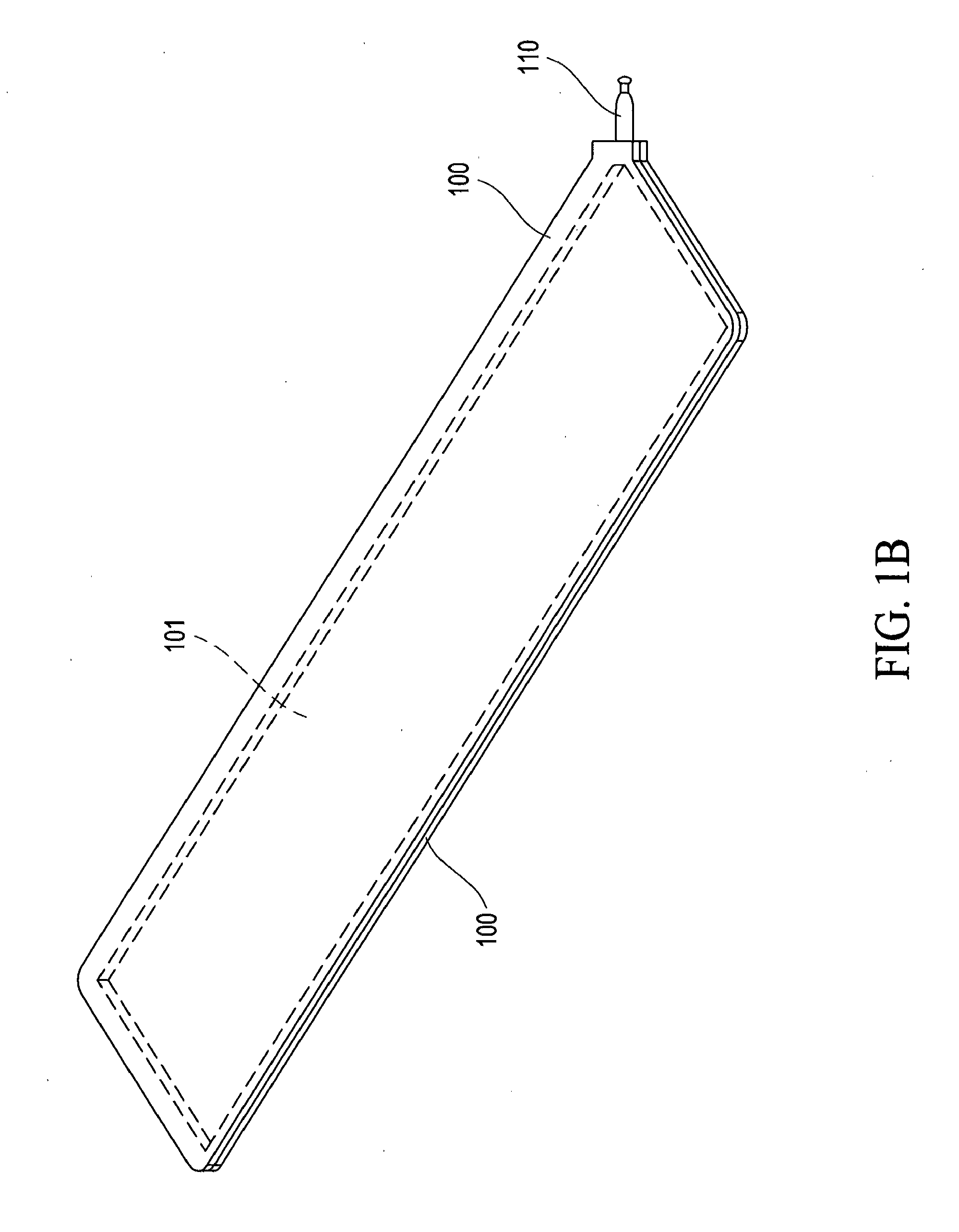

[0018]With reference to the drawings and in particular to FIGS. 1A-1D, which respectively show an exploded view of a heat plate according to a first embodiment of the present invention, a perspective view illustrating two boards of the heat plate coupled together, a perspective of the heat plate, and a cross-sectional view of the heat plate, the heat plate constructed in accordance with the present invention comprises two boards 100, a sealing tube 110, at least one first capillary layer 210, and at least one second capillary layer 220 and realizes functions of lowering temperature of a heat source, performing effective transfer of heat, and improving temperature reduction efficiency.

[0019]The two boards 100 are mated and coupled to each other so that the two boards 100 defined an accommodation chamber 101 therebetween. In a practical arrangement, one of the two boards 100 is structured to form a recess 102, or alternatively, both boards 100 are structured to form corresponding rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com