Method for preparing nano sillicalite-1 type total-silicalite molecular sieve

A kind of all-silicon molecular sieve, nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low yield of nano-silicalite-1 type all-silicon molecular sieve, achieve good performance, Effect of reduced diffusion resistance and high diffusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

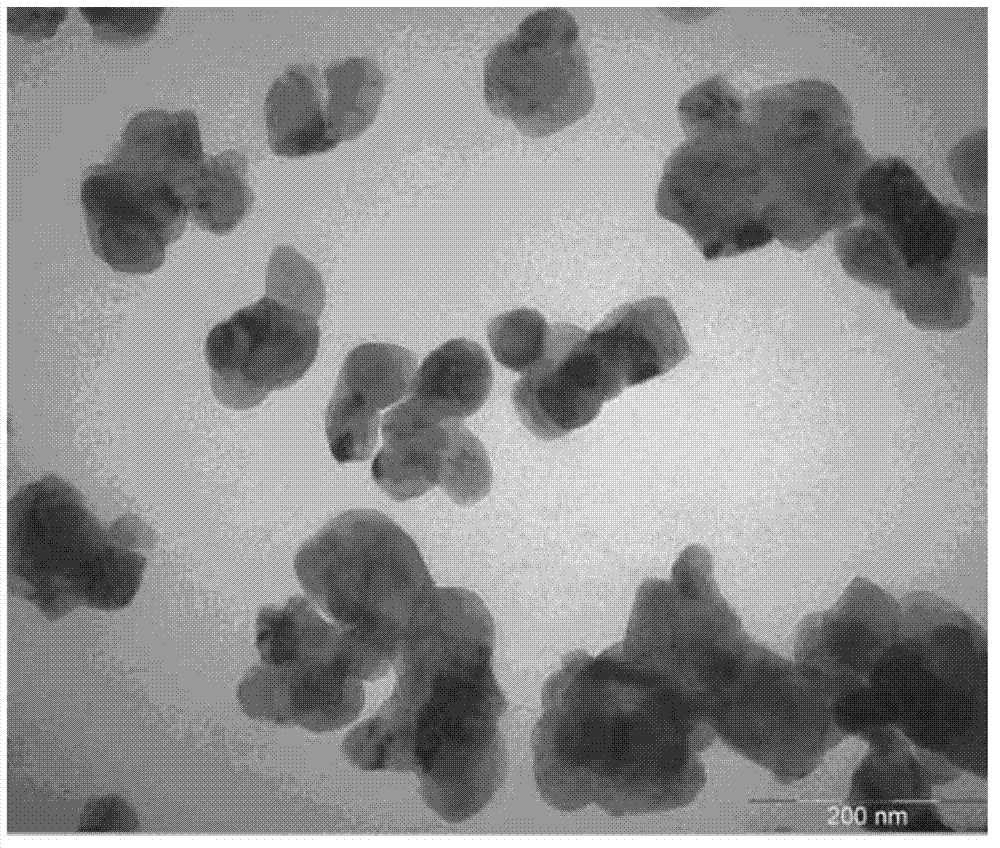

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment one: the preparation method of a kind of nano silicalite-1 type all-silicon molecular sieve in this embodiment is carried out according to the following steps:

[0013] One, take template agent, alkali source, silicon source and water, wherein the molar ratio of template agent, alkali source, silicon source and water is (1~4): (10~20): (80~100): (1000 ~2000), under the condition of 0℃~25℃, add template agent and alkali source into water in turn to obtain a mixed solution, then add silicon source to the mixed solution, and stir in a magnetic stirrer for 0.5~2h to obtain the mixture solidified glue system;

[0014] 2. Put the mixture gel system in an autoclave, and crystallize at a temperature of 90°C to 200°C for 24h to 48h. The crystallized product is washed, centrifuged, and dried in a vacuum oven, and then placed in a muffle furnace Calcined at 450°C for 4h-6h to prepare nano-silicalite-1 all-silicon molecular sieve.

[0015] The preparation meth...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the template in step 1 is tetrapropylamine hydroxide, n-butylamine or triethylamine. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the templating agent in step 1 is n-butylamine. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com