Ultraviolet-curing type optical resin adhesive and preparation method thereof

An optical resin, curing technology, applied in the direction of adhesive additives, adhesive types, polyurea/polyurethane adhesives, etc., to achieve the effect of improving durability and bonding reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0021] Synthesis Example 1 Synthesis of Trifunctional Polyether Urethane Acrylate [P1]

[0022] Add 120 grams of polyether trihydric alcohol (Bluestar Dongda EP-3600) with a hydroxyl value of 28 and 13.3 grams of isophorone diisocyanate into the reactor, and add 0.1 grams of dibutyltin dilaurate as a catalyst. React at 75°C for 2.5 hours, add 8.6 grams of hydroxyethyl acrylate, 0.1 grams of p-hydroxyanisole, and 0.3 grams of β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, continue React at 75°C for 2 hours, then cool and discharge to obtain trifunctional polyether urethane acrylate [P1].

Synthetic example 2

[0023] Synthesis Example 2 Synthesis of Difunctional Polyether Urethane Acrylate [P2]

[0024] Add 108 grams of polyether diol (Dow Voranol 4240) with a hydroxyl value of 28 and 10 grams of isophorone diisocyanate into the reactor, add 0.1 grams of dibutyltin dilaurate as a catalyst, and react at 75 ° C After 2.5 hours, add 2.5 grams of hydroxyethyl acrylate, 0.15 grams of p-hydroxyanisole, and 0.45 grams of β-(3,5-di-tert-butyl-4-hydroxyphenyl) isooctyl propionate, and continue to heat at 75 ° C. After reacting for 2 hours, cooling and discharging is bifunctional polyether polyurethane acrylate [P2].

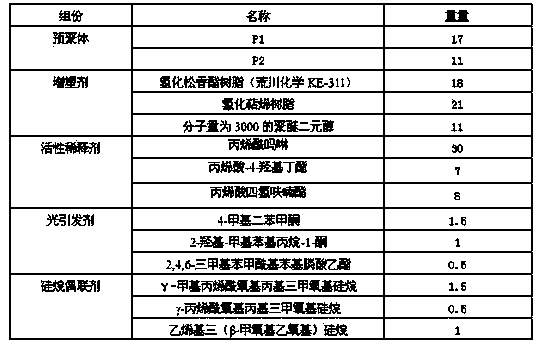

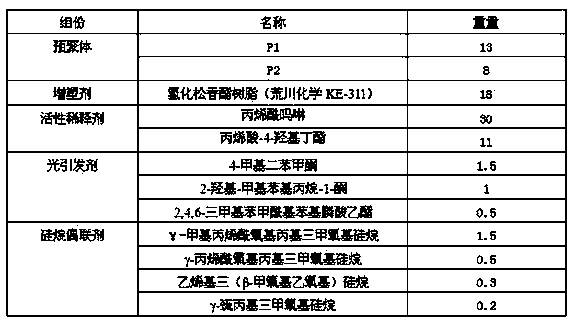

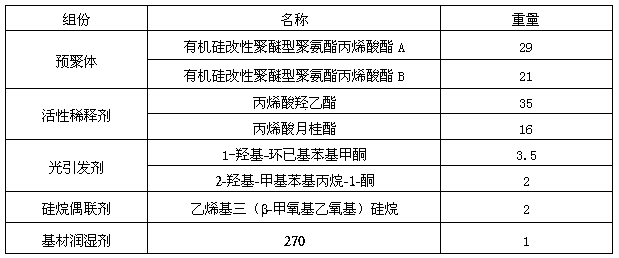

[0025] Mix P1, P2, plasticizer, reactive diluent, photoinitiator, and silane coupling agent synthesized in the above synthesis example in a stirring tank according to the weight in the table below until uniform, vacuumize and defoam, and discharge. Example 1

Embodiment 1

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure shrinkage | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com