Method for deacidifying biodiesel

A biodiesel and deacidification technology, which is applied in the fields of biofuel, petroleum industry, fat production, etc., can solve the problems of increased energy consumption, no other removal of biodiesel, huge equipment, etc., and achieve the effect of reducing the acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

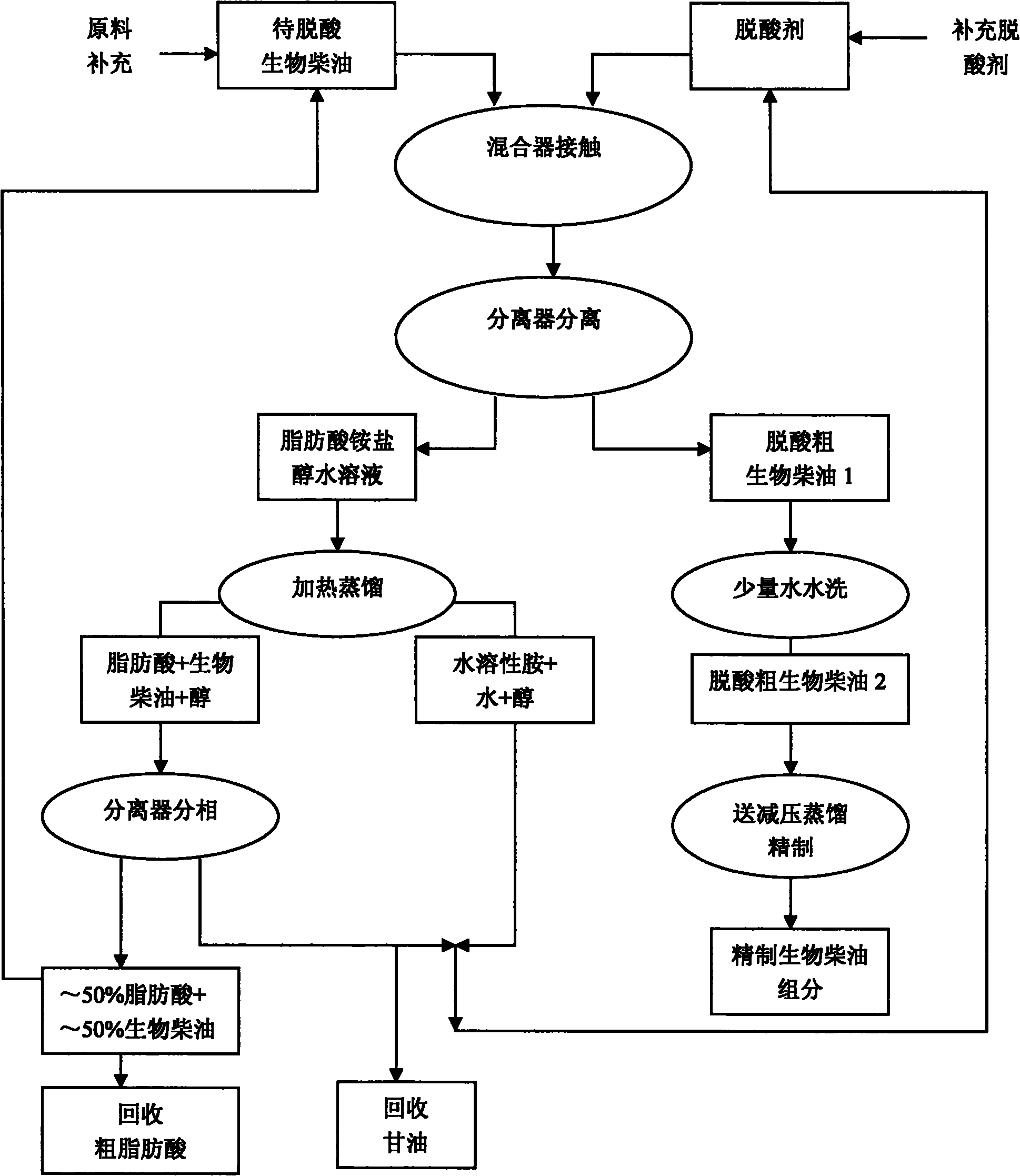

Method used

Image

Examples

example 1

[0027] Crude biodiesel feedstock: acid value 9.8mgKOH / g

[0028] Deacidification agent composition (mass fraction): 40% methanol + 55% water + 5% ammonia

[0029] Take 100mL of crude biodiesel, put it in a 250mL separating funnel, put it in a 60°C water bath, add 30ml of deacidification agent, keep the temperature for 30min, shake it fully for 5min, and let it stand in the water bath for 10min. It is found that the two phases are clearly separated, and the lower water phase From colorless to deep yellow, the two phases were separated and the following treatments were carried out respectively.

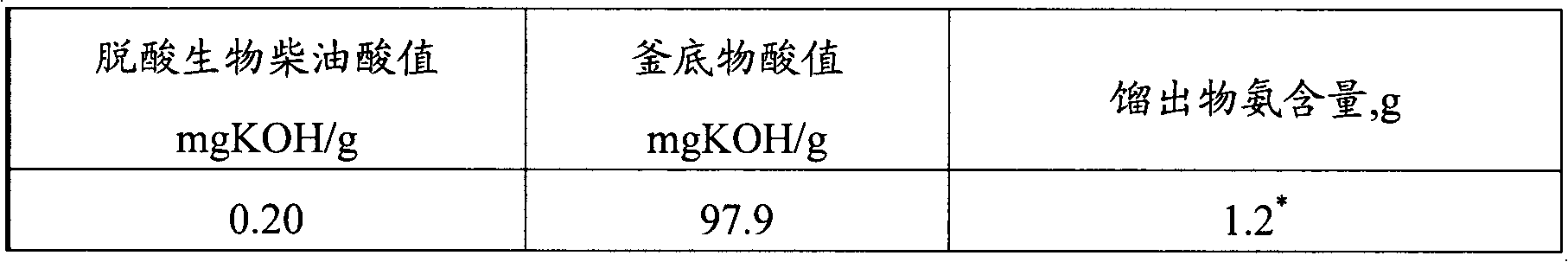

[0030] At 60°C, wash the upper oil phase with water: oil = 1: 10 and settling and dehydrating, then measure the acid value of the oil phase; transfer the lower water phase to a distillation flask for atmospheric flash evaporation, reclaim the distillate, and remove the tail Insert the connecting tube into the receiving bottle, absorb the distilled gas and liquid with water, and measure...

example 2

[0035] Crude biodiesel raw material: acid value 8.70mgKOH / g;

[0036] Deacidification agent composition (mass fraction): 55% ethanol + 42% water + 3% ammonia.

[0037] Refined mixer: Φ10×500mm fiber membrane reactor, fiber wire material is 316L stainless steel, stainless steel wire diameter is 0.10mm, and the effective filling rate of refined mixer is 51%.

[0038] Two micropumps are used to measure crude biodiesel and deacidification agent respectively. After preheating the crude biodiesel to 70°C, the two enter the reactor at the same time at 1000mL / h and 200mL / h respectively. The bottom of the settling tank at the lower end collects the water phase, and the outlet at the top of the settling tank collects deacidified biodiesel.

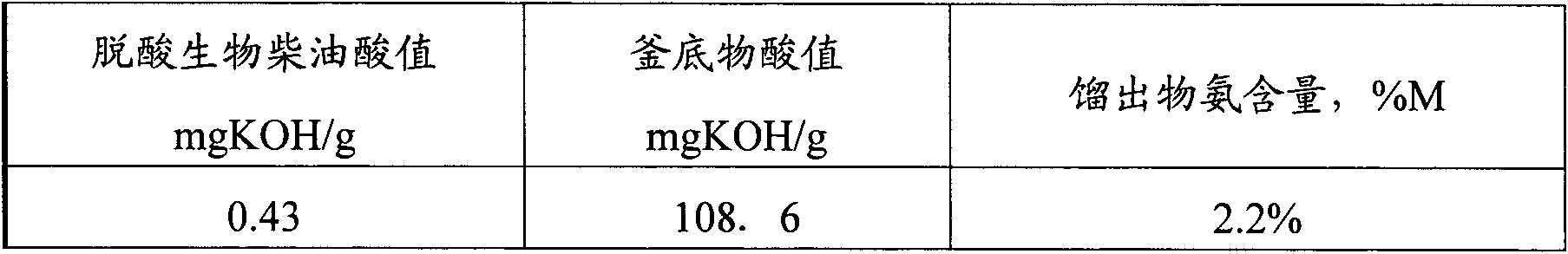

[0039] The collected oil phase and water phase were treated by a method similar to that of Example 1, and the results obtained are shown in Table 2.

[0040] Table 2 Fiber membrane contact deacidification test results

[0041]

Embodiment 3

[0043] Biodiesel methylated material: acid value 8.7mgKOH / g, containing about 8% (mass fraction) of unseparated glycerin, 0.5% (mass fraction) of methanol, and the rest being fatty acid methyl esters.

[0044] Deacidification agent composition (mass fraction): 10% ammonia + 90% water.

[0045] Refined mixer: Φ10×500mm fiber membrane reactor, fiber wire material is 316L stainless steel, stainless steel wire diameter is 0.10mm, and the effective filling rate of refined mixer is 51%.

[0046] Two micropumps were used to meter crude biodiesel and deacidification agent containing glycerol and methanol respectively. After the biodiesel was preheated to 70°C, the two were simultaneously fed into the reactor at 1000mL / h and 250mL / h respectively. The bottom of the settling tank at the lower end of the fiber membrane reactor collects the water phase, and the outlet at the top of the settling tank collects deacidified biodiesel.

[0047] The collected oil phase and water phase, for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com