Backlight module and light guide plate

A technology of backlight module and light guide plate, applied in the direction of light guide, light guide of lighting system, optics, etc., can solve the problems of poor light diffusion efficiency, inability to obtain geometric shapes, poor surface structure Gc molding, etc., to solve uneven diffusion , Improve light diffusion efficiency, increase the effect of overall roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description will illustrate embodiments of the present invention with reference to related drawings, so that anyone skilled in the art can implement the present invention. Although there are differences in the embodiments of the present invention, the structures or features described herein are used for any implementation, without departing from the scope of the present invention, it can be implemented in other embodiments, not just the following implemented in the manner described above. In addition, the arrangement and position of the individual components in each disclosed embodiment can be modified appropriately without departing from the scope of the present invention, so the protection scope of the present invention should be defined by the appended claims.

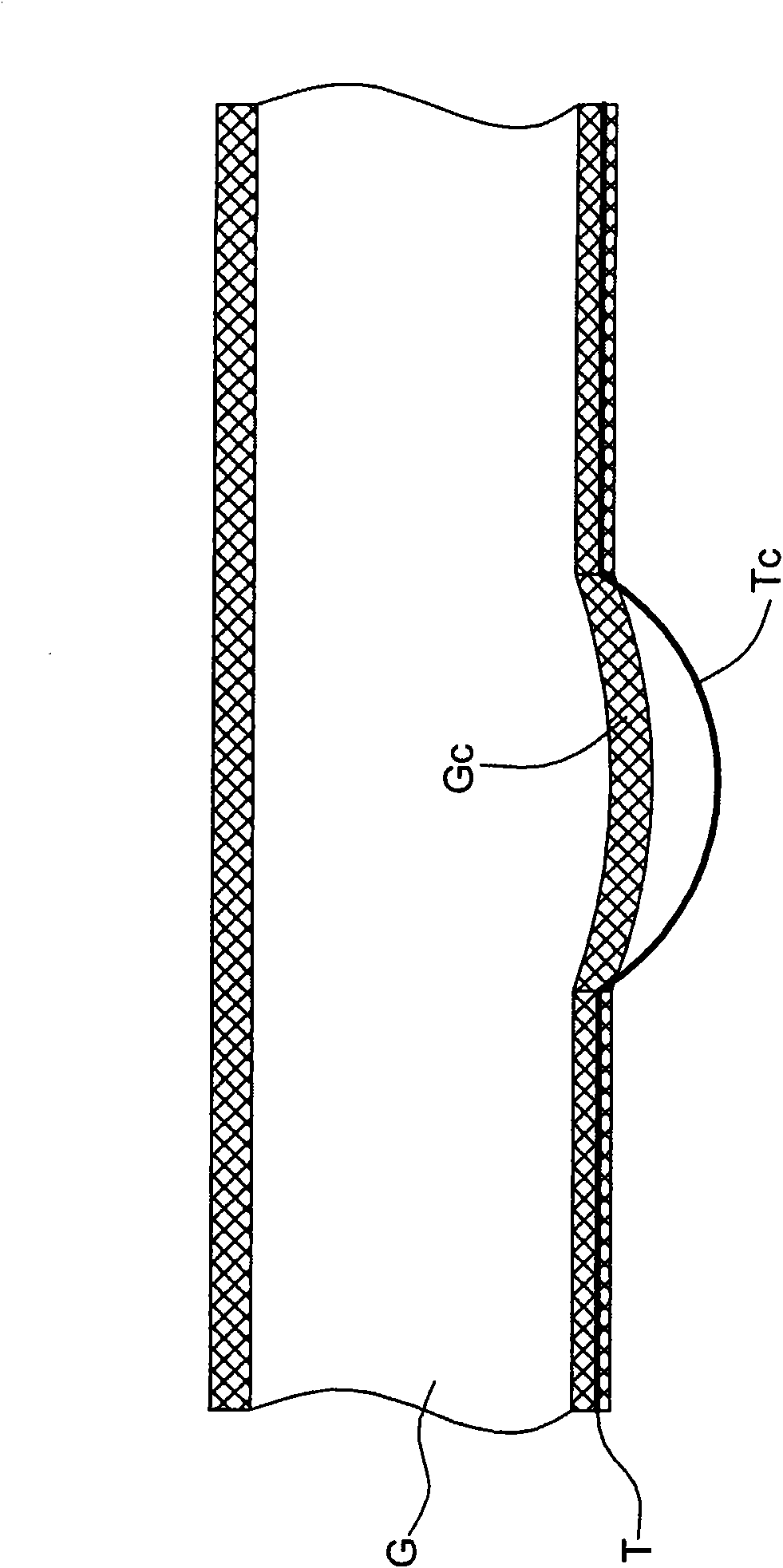

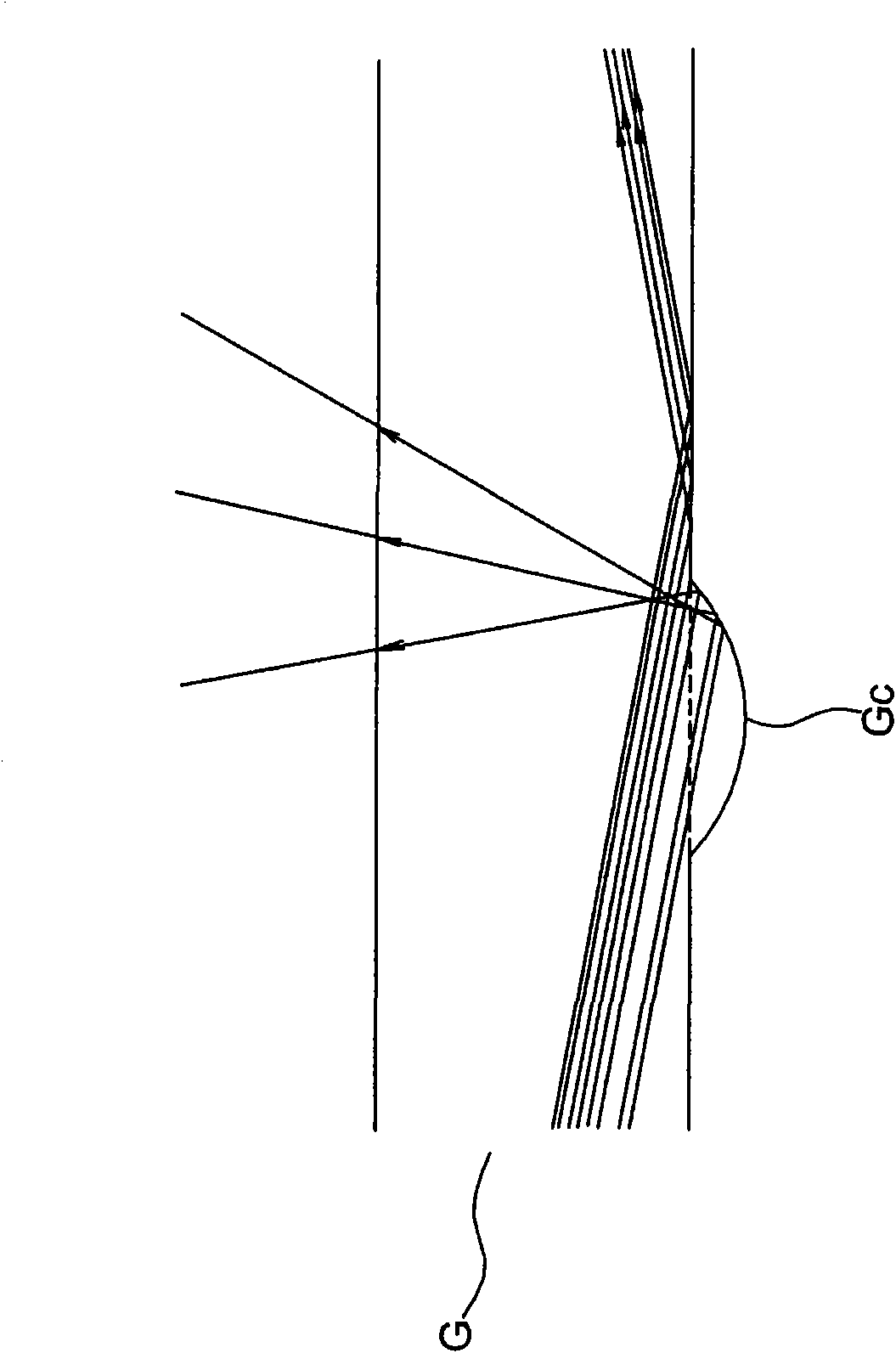

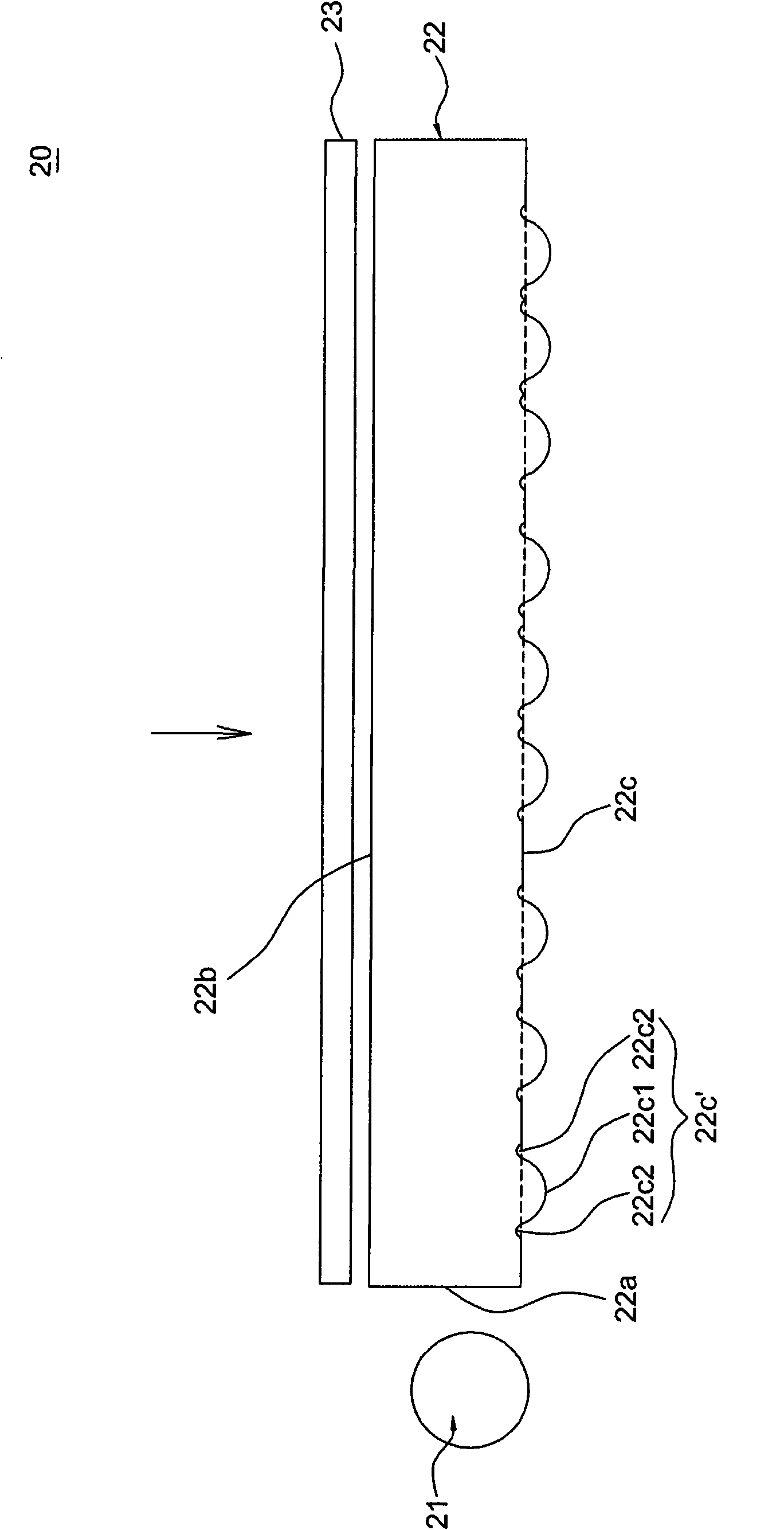

[0020] figure 2 is a schematic diagram showing a backlight module according to an embodiment of the present invention. The backlight module 20 includes a light source 21 , a light guide plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com