Super-sonic diffuser for super-sonic vortex flow natural gas separator

A supersonic, diffuser technology, applied in the direction of the cyclone axial reversible device, cyclone device, etc., can solve the problem of the reduction of the pressure recovery ability of the supersonic cyclone separator, the energy loss, and the reduction of the diffuser. efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

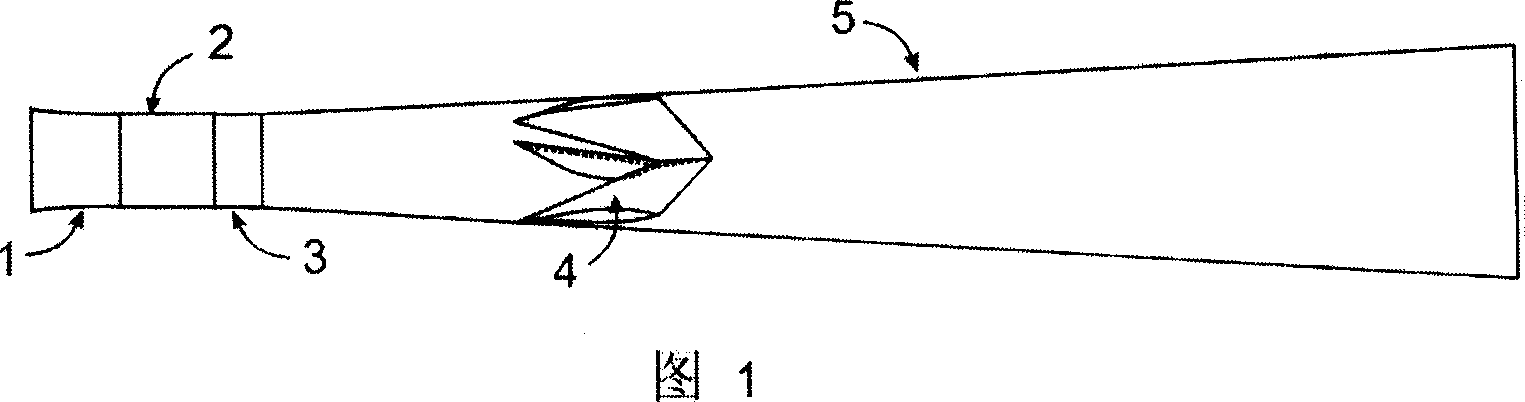

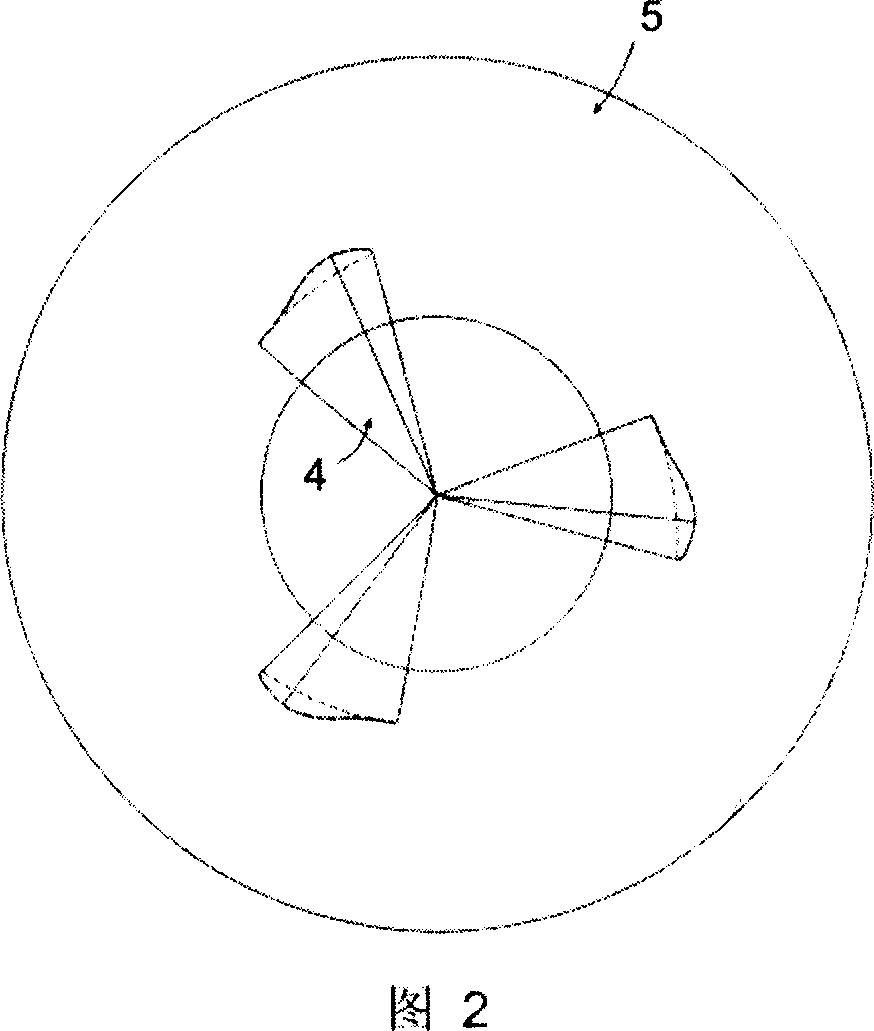

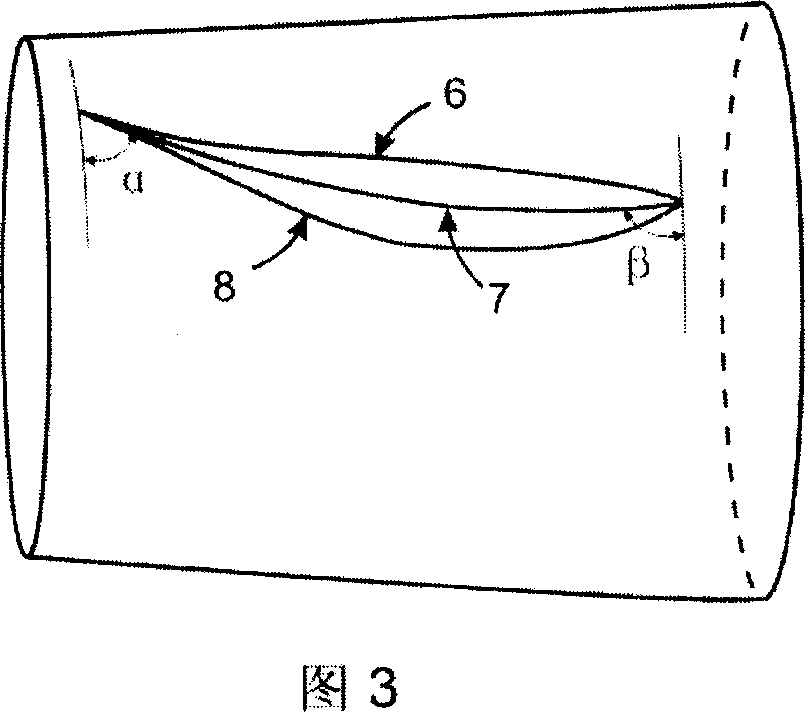

[0015] The accompanying drawing is an example of a typical supersonic diffuser designed and processed according to the purpose of the present invention. The separation section of the supersonic cyclone natural gas separator where the supersonic diffuser is located is a cylindrical shell. Fig. 1 is a front view of a supersonic diffuser, and Fig. 2 is a side view of a supersonic diffuser. The supersonic diffuser is composed of shrinkage pipe section 1 , straight pipe section 2 , arc-shaped wall surface expansion pipe section 3 , linear wall surface expansion pipe section 5 and guide fins 4 . In this example, the profile curve of the shrinking pipe section is a cubic polynomial, the inlet diameter is 17.7mm, the length is 15.3mm, the shrinkage angle is 30°, and the end tangent is parallel to the axial direction. The length of the expansion pipe section is 230.5mm, the expansion angle is 6°, and the radius of the curve of the arc section is 20 times the diameter of the straight s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com