Optical diffusion film and preparation method thereof

A technology of optical diffusion and diffusion layer, used in optics, optical components, instruments, etc., can solve the problems of difficult to control particle distribution uniformity, poor resin adhesion, film curling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

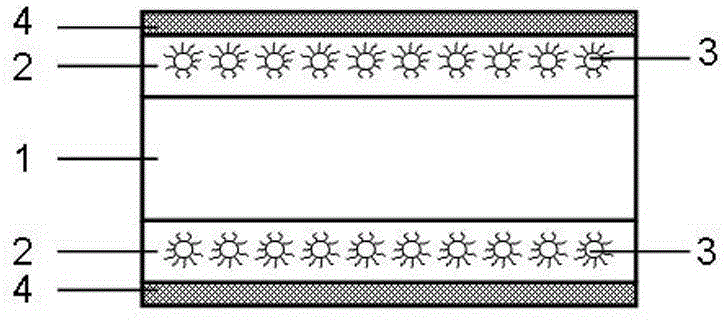

Image

Examples

Embodiment 1

[0060] (1) Preparation of diffusion layer coating solution

[0061] a. Add 8.52 parts by weight of tetraethyl orthosilicate, 3.35 parts by weight of silane coupling agent GX560, 69 parts by weight of ethanol, 9 parts by weight of water and 0.75 parts by weight of 0.15mol / L dilute hydrochloric acid into the stirring tank A , stirred at room temperature for 1 hour, and set aside;

[0062] b. Add 5.59 parts by weight of A-101 thermoplastic acrylic resin and 46 parts by weight of ethyl acetate into the stirring tank B, and stir for 1 hour until the resin is completely dissolved;

[0063] c. Add the solution in stirring tank B into stirring tank A, and stir at room temperature for 2 hours until the mixture is uniform. The diffusion layer coating solution with a solid content of 16.18% and a viscosity of 1769 cps was prepared for subsequent use.

[0064] (2) Preparation of hardened layer coating solution

[0065] Add 4.37 parts by weight of low-viscosity polyester acrylate, 27.27...

Embodiment 2

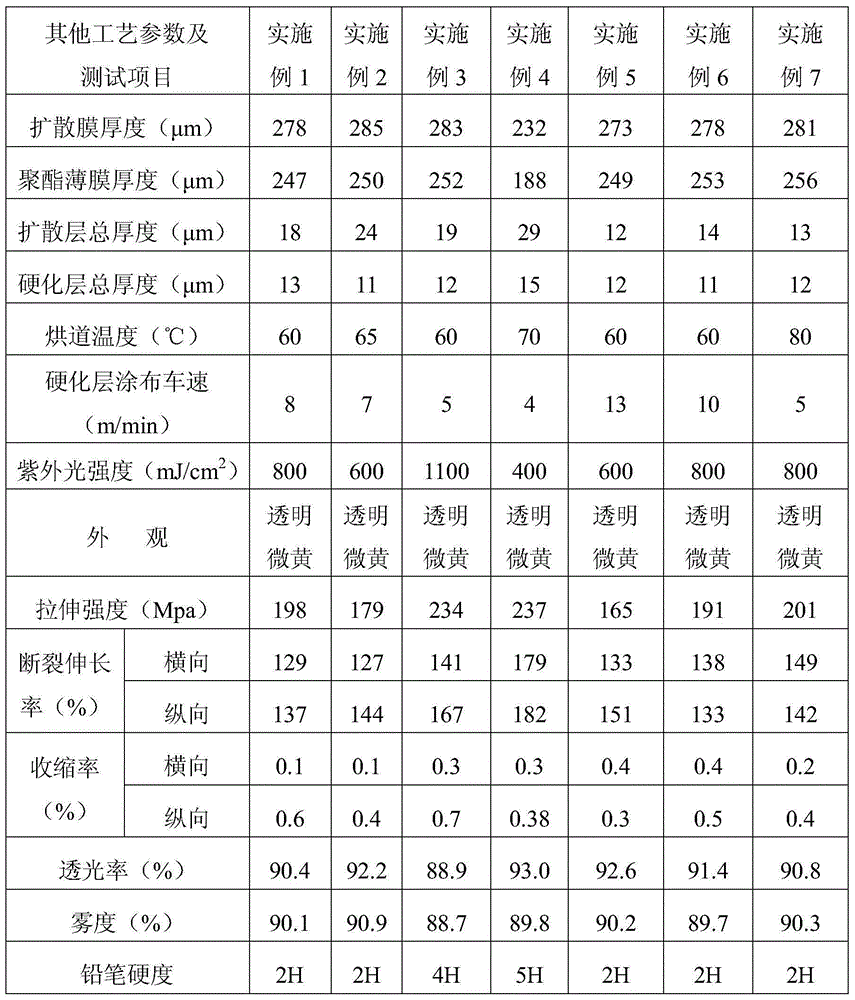

[0070] Taking Example 1 as the basic scheme of this example, the amount of raw materials and the types thereof are replaced by: the amount of silicon source tetraethyl orthosilicate is 17 parts by weight, the amount of A-101 thermoplastic acrylic resin is 14 parts by weight, photoinitiator 184 Replaced with 651, the amount of photoinitiator 651 is 0.94 parts by weight, and the amount of other raw materials and production conditions remain unchanged. Among them: the temperature of the drying tunnel, the coating speed of the hardened layer and the intensity of ultraviolet light are shown in Table 1 below.

[0071]The solid content of the diffusion layer coating solution was 39.88%, and the viscosity was 2981 cps.

Embodiment 3

[0073] Taking Example 1 as the basic scheme of this example, the amount and variety of raw materials are replaced by: the amount of silane coupling agent GX560 and GX561 is 11.7 parts by weight (ratio is 50%:50%), dilute hydrochloric acid of 0.15mol / L The amount used is 2 parts by weight, the amount of low-viscosity polyester acrylate is 9 parts by weight, the amount of hexafunctional aliphatic urethane acrylate is 55 parts by weight, and the amount of other raw materials and production conditions remain unchanged. Among them: the temperature of the drying tunnel, the coating speed of the hardened layer and the intensity of ultraviolet light are shown in Table 1 below.

[0074] The solid content of the diffusion layer coating solution was 23.10%, and the viscosity was 2043 cps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com