Ultrathin Nano-DLC coating for mobile phone camera mold

A mobile phone camera and mold technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of precision optical mold dimensional accuracy, affecting the mirror degree of camera mold, etc., to improve the production yield rate, Increase the service life and solve the effect of sticking mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

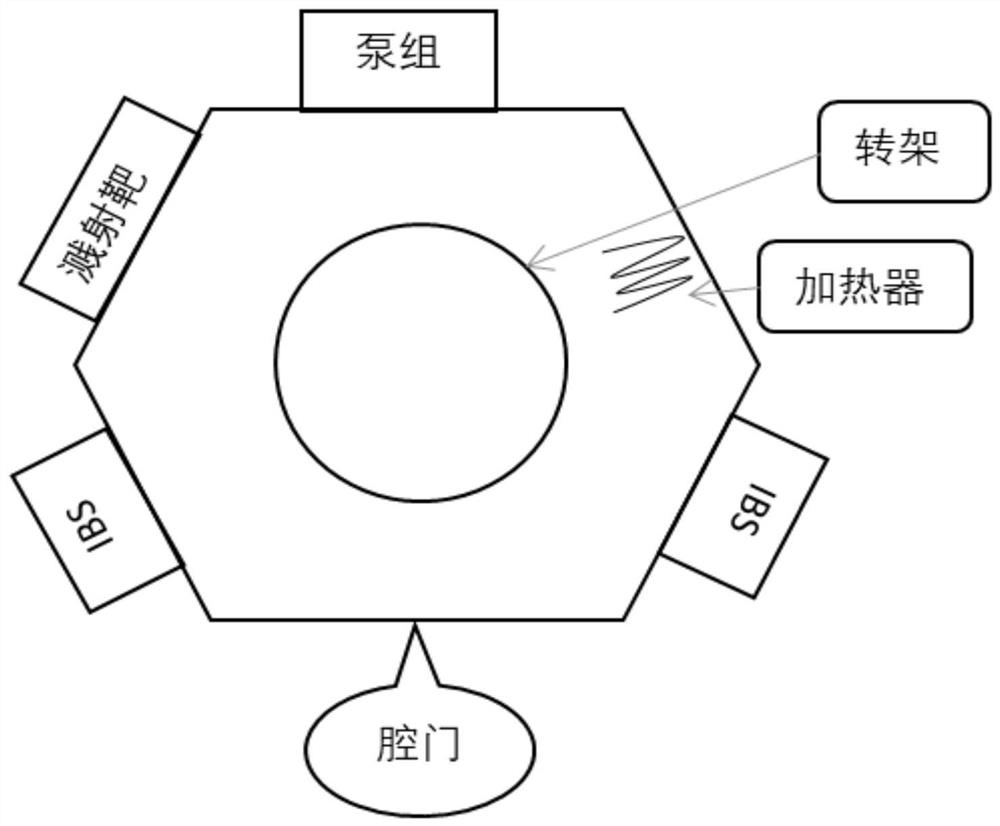

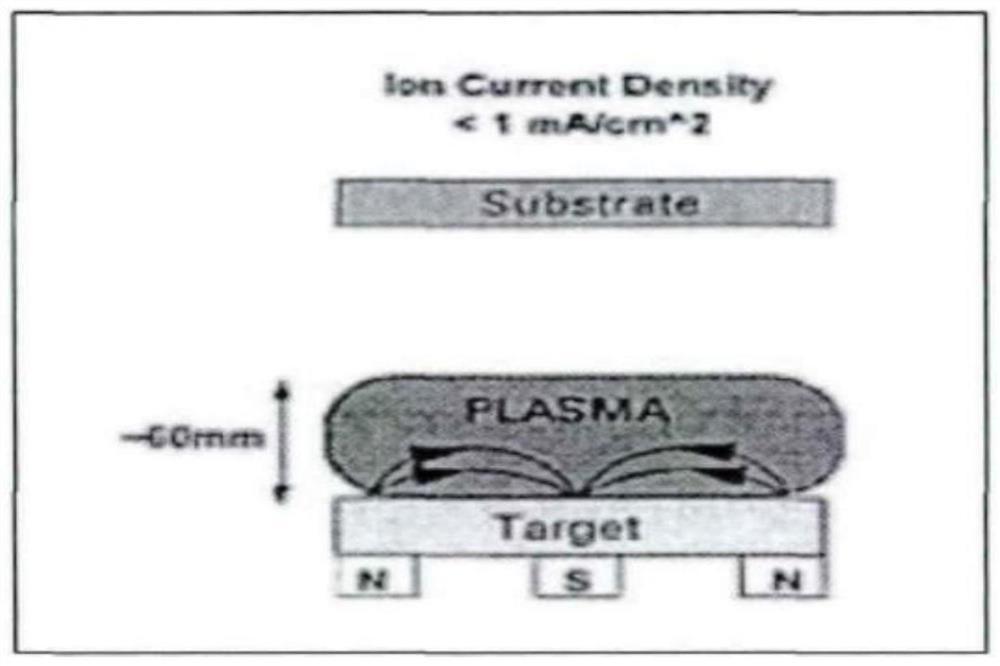

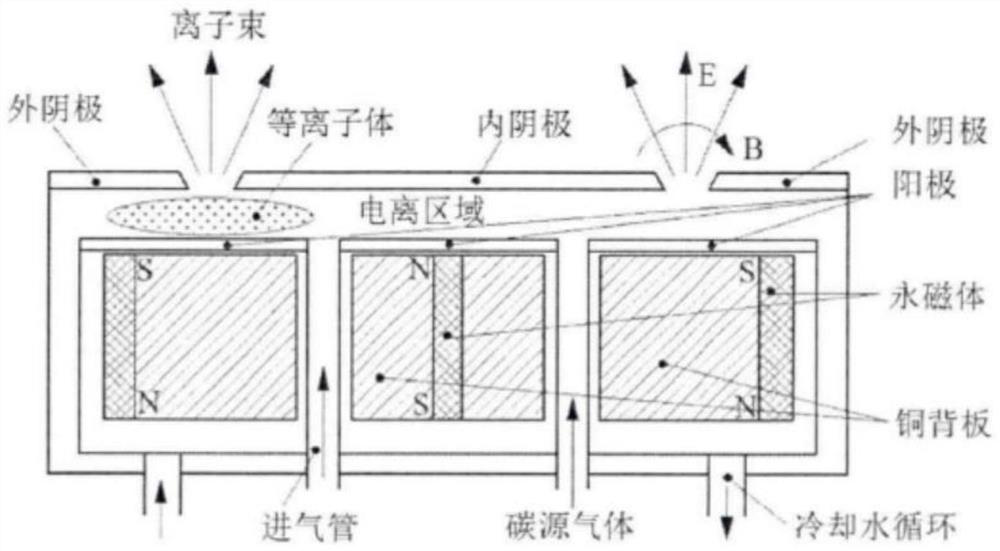

[0042] Please refer to figure 1 , figure 2 and image 3 , figure 1 The cavity process flow diagram of the first embodiment of the ultra-thin Nano-DLC coating for the mobile phone camera mold provided by the present invention; figure 2 It is a schematic diagram of magnetron sputtering deposition of the present invention; image 3 It is a schematic diagram of the ion beam structure of the anode layer of the present invention. Ultra-thin Nano-DLC coating for mobile phone camera molds, made by the following methods:

[0043] S1. Open the chamber door, clamp the cleaned products to the turntable, and close the chamber door after confirming that the turntable is smooth and free of jamming;

[0044] S2. Find the pump set corresponding to the pumping on the software interface, and vacuum the cavity according to the pumping standard;

[0045] S3. When the cavity is pumped to 5.0E-3Pa, set the heater temperature and turn on the heater to start heating;

[0046] S4. After waitin...

no. 2 example

[0068] Please refer to Figure 4 and Figure 5 , based on the ultra-thin Nano-DLC coating for mobile phone camera molds provided in the first embodiment of the application, the second embodiment of the application proposes another ultra-thin Nano-DLC coating based on mobile phone camera molds DLC coating. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0069] Specifically, the difference based on the ultra-thin Nano-DLC coating used for the mobile phone camera mold provided by the second embodiment of the application is that based on the ultra-thin Nano-DLC coating used for the mobile phone camera mold is also included in the The detection device 1 used for visual inspection of products, the detection device 1 includes a support frame 11, the top of the support frame 11 is fixedly connected with a mounting horizontal plate 12, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com