Plasma treatment device and plasma treatment method for polymer material surface modification

A polymer material, plasma technology, applied in ultrasonic/sonic fiber processing and other directions, can solve the problems of uneven quality of polymer surface modification, difficulty in making radio frequency or microwave power supply, and it is not easy to achieve stable discharge, so as to avoid burning. Effects of etch perforation and thermal damage, improved wettability, moderate temperature and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

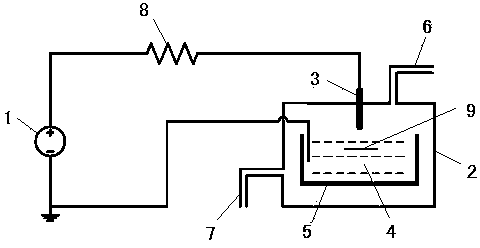

[0039] Such as figure 1 Shown is a schematic structural view of an embodiment of a plasma treatment device for surface modification of polymer materials according to the present invention. The plasma treatment device used in this embodiment for surface modification of polymer materials includes a DC power supply 1 and a reaction chamber 2. The reaction chamber 2 is correspondingly provided with a metal anode 3 and a liquid cathode 4 connected to the DC power supply 1 respectively, and the reaction The chamber 2 is provided with a container 5 for containing the liquid medium of the liquid cathode 4, and the metal anode 3 is arranged directly above the liquid surface of the liquid cathode 4, and the reaction chamber 2 is also provided with an air intake system for the circulation of the gas medium.

[0040]Preferably, the reaction chamber 2 of this embodiment is provided with an adjustment device for adjusting the distance between the metal anode 3 and the liquid cathode 4, and ...

no. 2 example

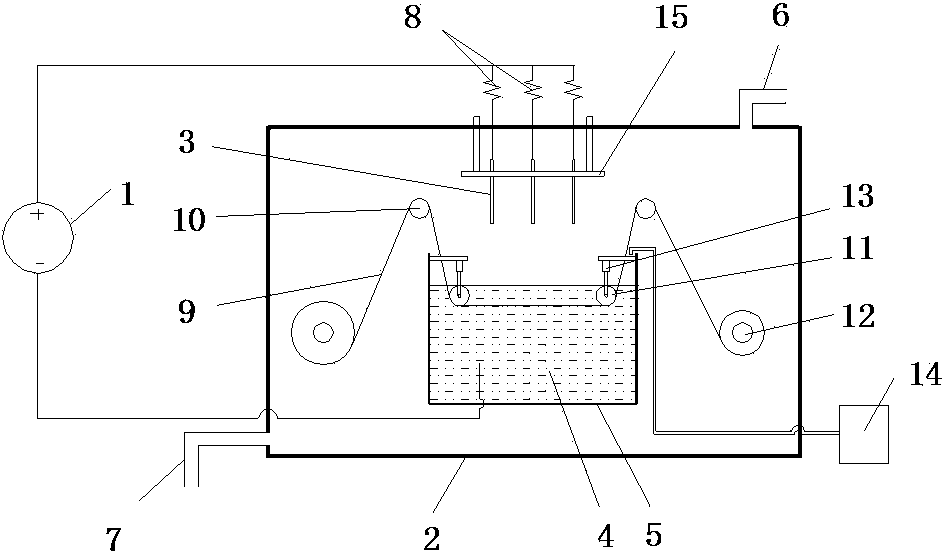

[0047] Such as figure 2 Shown is a schematic structural view of the second embodiment of the plasma treatment device for surface modification of polymer materials according to the present invention. The plasma treatment device used in this embodiment for surface modification of polymer materials includes a DC power supply 1 and a reaction chamber 2. The reaction chamber 2 is correspondingly provided with a metal anode 3 and a liquid cathode 4 connected to the DC power supply 1 respectively, and the reaction The chamber 2 is provided with a container 5 for containing the liquid medium of the liquid cathode 4, and the metal anode 3 is arranged directly above the liquid surface of the liquid cathode 4, and the reaction chamber 2 is also provided with an air intake system for the circulation of the gas medium.

[0048] In this embodiment, the reaction chamber 2 is provided with a driving device for continuous feeding of the polymer material. The driving device includes a driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com