A kind of high volume fraction sic/cu particle reinforced al-based metal composite material and its preparation method

A high volume fraction, particle reinforced technology, applied in the field of high volume fraction SiC/Cu particle reinforced Al-based metal composites and their preparation, to achieve the effect of improving density, increasing surface energy, and high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a high volume fraction SiC / Cu particle reinforced Al-based metal composite material of the present invention comprises the following steps:

[0035] S1. Disperse silicon carbide powder with a particle size of 50-100nm in anhydrous ethanol by ultrasonic-assisted stirring, then add Al powder with a particle size of 5-10μm and a solid content of 95%-97% for rolling ball milling at a revolution speed of 2000~ 2500r / min, rotation rate 800-1000r / min, stirring for 3-5min, then vacuum-evaporate ethanol for 1-3min, then vacuum-dry at 60-80°C for 1-2h to obtain surface-modified aluminum powder;

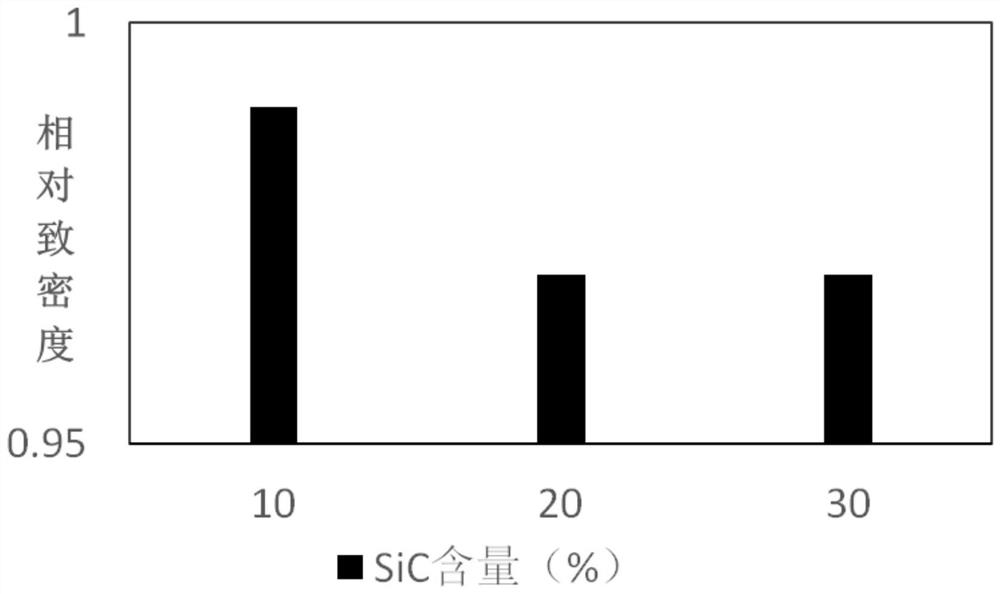

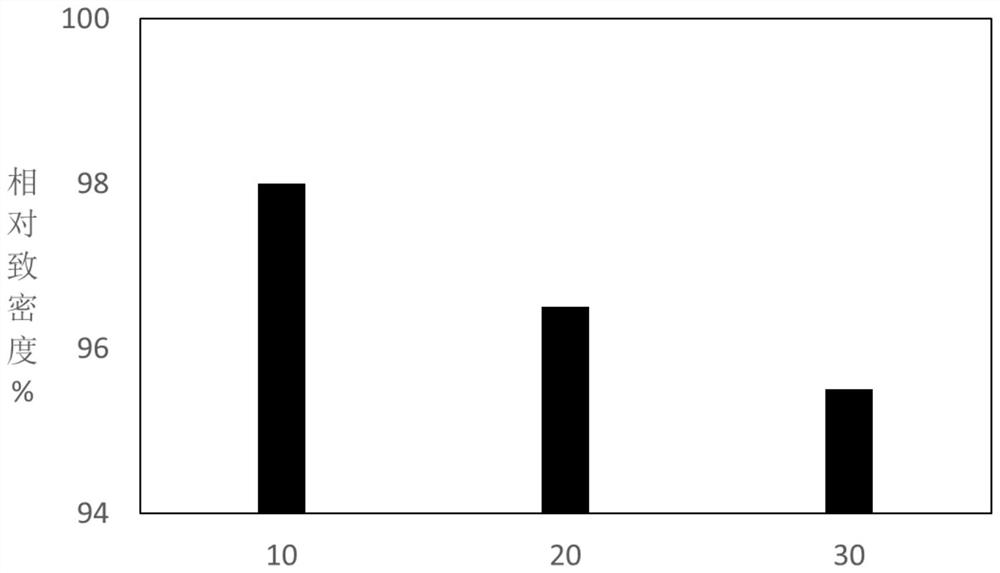

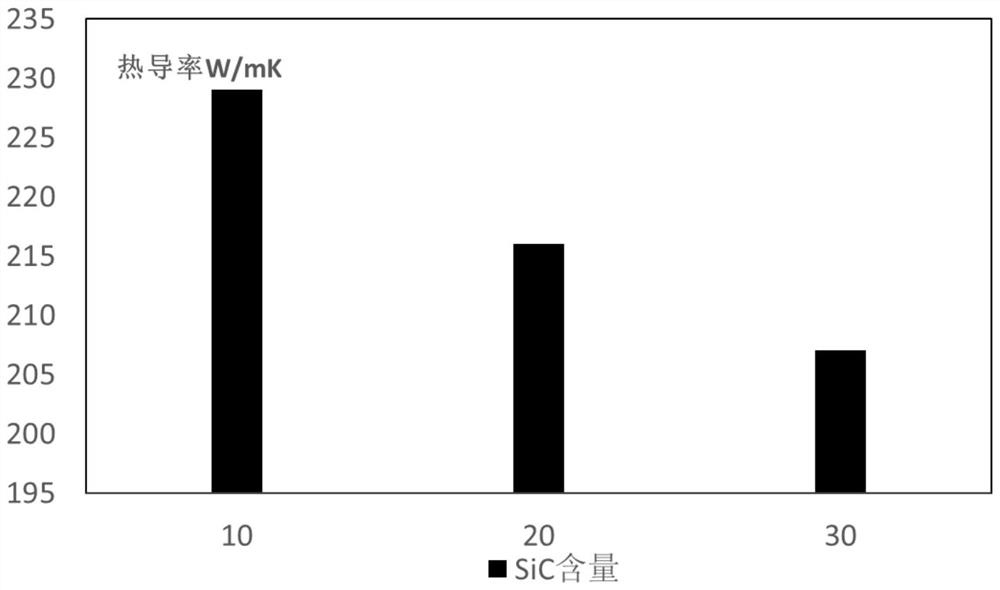

[0036] S2. Mix the modified aluminum powder obtained in step S1 with submicron silicon carbide powder of 500nm to 1 μm and copper powder of 1 to 2 μm, and dry-mix at a speed of 200 to 500 r / min for 5 to 6 hours, wherein the submicron The content of high-grade silicon carbide is 10% to 30%, the content of copper is 20% to 30%, and the diameter of the grinding ball i...

Embodiment 1

[0042] S1. Disperse silicon carbide powder with a particle size of 50nm in absolute ethanol by ultrasonic-assisted stirring, then add Al powder with a particle size of 5 μm and a solid content of 95% for rolling ball milling, with a revolution speed of 2000r / min and a rotation speed of 800r / min , after stirring for 3 minutes, vacuum-evaporating ethanol for 1 minute, and then vacuum-drying at 60°C for 1 hour to obtain surface-modified aluminum powder;

[0043] S2. Mix the modified aluminum powder obtained in step S1 with 500nm submicron silicon carbide powder and 1 μm copper powder, and dry mix at a speed of 200r / min for 5 hours, wherein the content of submicron silicon carbide is 10%. , the content of copper is 20%, the diameter of the ball is 5mm;

[0044] S3. Press the uniformly mixed powder in step S2 with cold isostatic pressing at a pressure of 200 MPa to obtain a composite material blank, and then perform vacuum calcination to obtain a dense composite material at a tempe...

Embodiment 2

[0047] S1. Disperse silicon carbide powder with a particle size of 70nm in absolute ethanol by ultrasonic-assisted stirring, then add Al powder with a particle size of 7 μm and a solid content of 95% for rolling ball milling, with a revolution speed of 2200r / min and a rotation speed of 850r / min , after stirring for 3 minutes, vacuum-evaporating ethanol for 1 minute, and then vacuum-drying at 65° C. for 1 hour to obtain surface-modified aluminum powder;

[0048] S2. Mix the modified aluminum powder obtained in step S1 with 700nm submicron silicon carbide powder and 1 μm copper powder, and dry mix at a speed of 250r / min for 5 hours, wherein the content of submicron silicon carbide is 15%. , the content of copper is 22%, and the diameter of the grinding ball is 5mm;

[0049] S3. Press the uniformly mixed powder in step S2 with cold isostatic pressing at a pressure of 240 MPa to obtain a composite material blank, and then perform vacuum calcination to obtain a dense composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com