Carbon microspheres with high specific surface area and preparation method for carbon microspheres with high specific surface area

A high specific surface area, carbon microsphere technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex preparation process of spherical activated carbon, complex preparation process and equipment, poor sphericity of activated carbon products, etc. Enhance the effect of activated pore formation, low cost and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Mix 5 g of carbon black, 20 g of KOH, 5 g of wheat starch and 100 g of water, and stir at 20°C for 1 h. Use a spray dryer to dry and granulate the solution. The spray drying inlet temperature is 230°C, and the outlet temperature is 70-150°C; activate for 10 hours at 800°C in a water vapor atmosphere, and wash with 0.1mol / L hydrochloric acid and water. After drying, high specific surface area carbon microspheres are obtained.

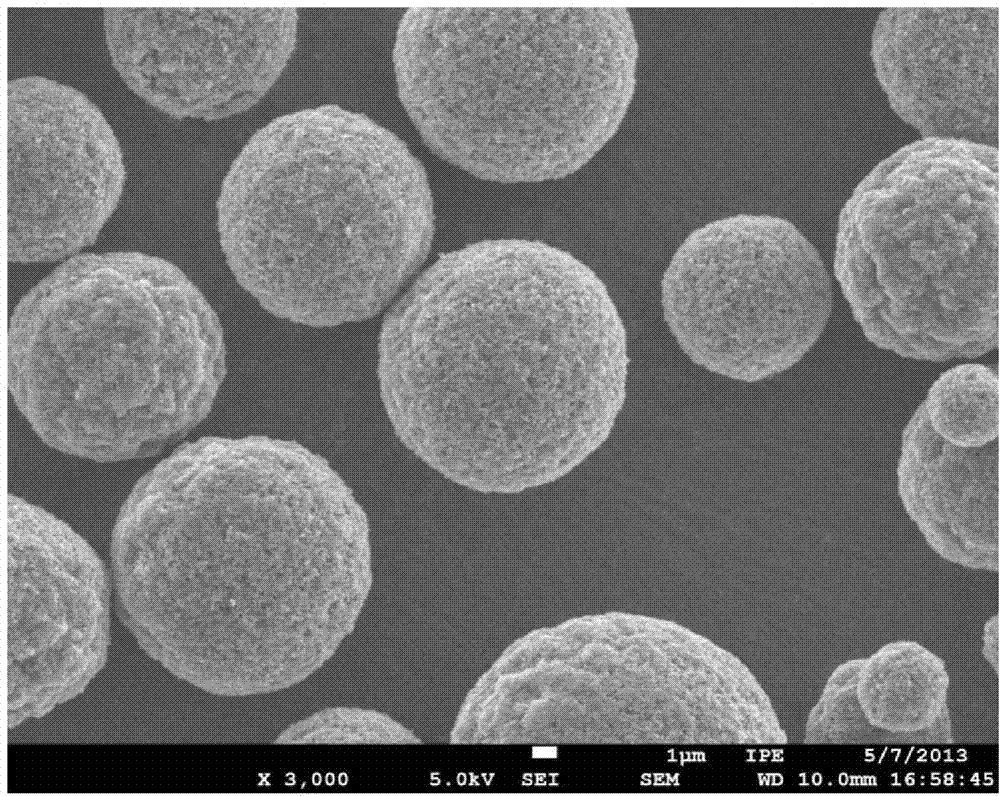

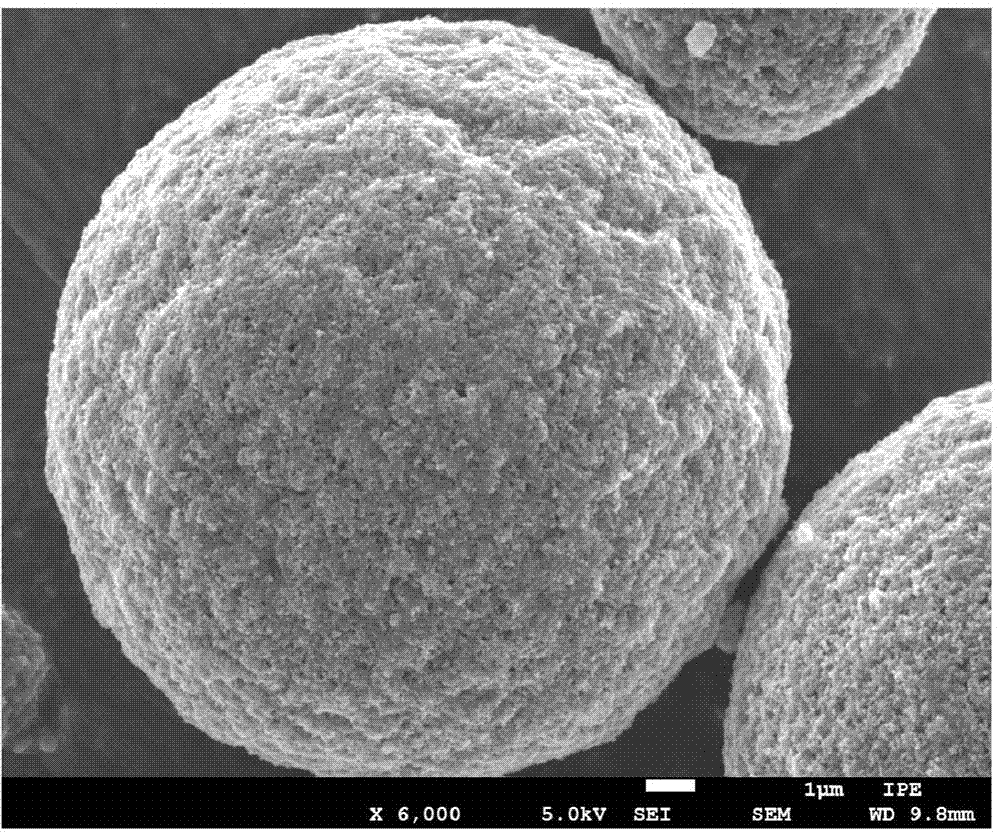

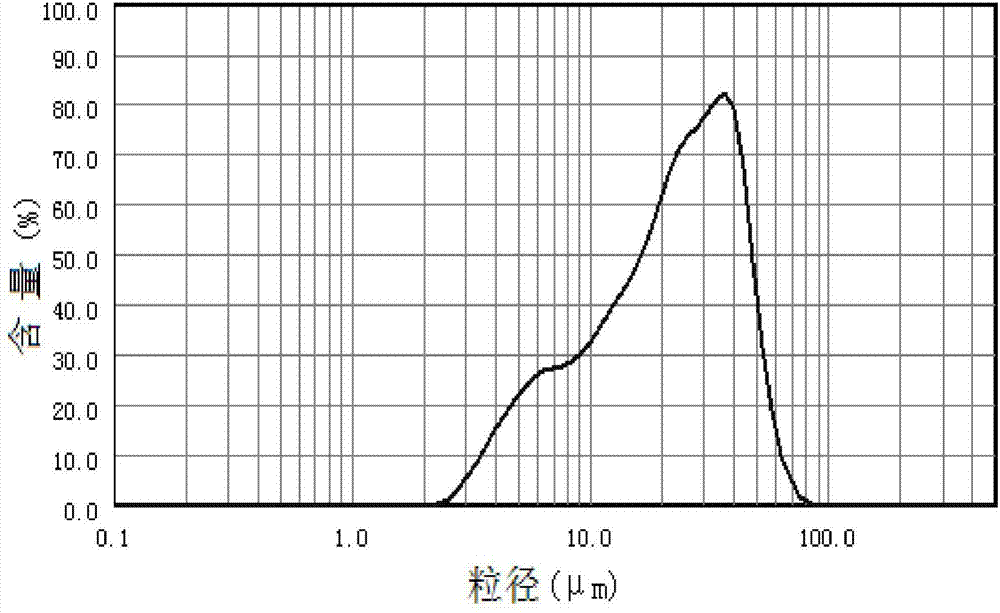

[0061] The high specific surface area carbon microspheres prepared above were used to observe the morphology of the samples with a JSM-7001F field emission scanning electron microscope produced by JEOL Oxford Instruments. figure 1 , figure 2 It is the SEM image of the high specific surface area carbon microspheres obtained in Example 1. It can be seen from the figure that the material has a high degree of sphericity, and the carbon microspheres are composed of carbon black particles, and mesoporous voids are formed between the carbon black part...

Embodiment 2

[0064] Mix 1000 g of KOH, 10 g of polyvinyl alcohol and 1000 g of water, and stir at 60° C. for 3 h. Gained slurry and 1000 grams of charcoal powder are granulated by a disc granulator to obtain primary spherical activated carbon microspheres. Then the obtained material was activated at 900° C. for 24 h under the atmosphere of water vapor and carbon monoxide, washed with 0.1 mol / L hydrochloric acid and water, and dried to obtain carbon microspheres with high specific surface area.

[0065] Particle photos see Figure 4 , it can be seen from the figure that the diameter of the high specific surface area carbon microspheres is 3-5 mm, the sphericity of the particles is high, and the particles are uniform.

Embodiment 3

[0067] Mix 15 grams of petroleum coke powder, 8 grams of KOH, 12 grams of sucrose and 260 grams of water, and stir at 50°C for 1 hour. Use a spray dryer to dry and granulate the solution. The spray drying inlet temperature is 230°C, and the outlet temperature is 70-150°C; After washing with hydrochloric acid and water, the carbon microspheres with high specific surface area are obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com