Wet-conduction quick-drying fabric

A moisture-conducting and quick-drying, wet-quick-drying technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of wet and cold, unfavorable rapid evaporation of water, adhesion to the body surface or dripping along the body surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

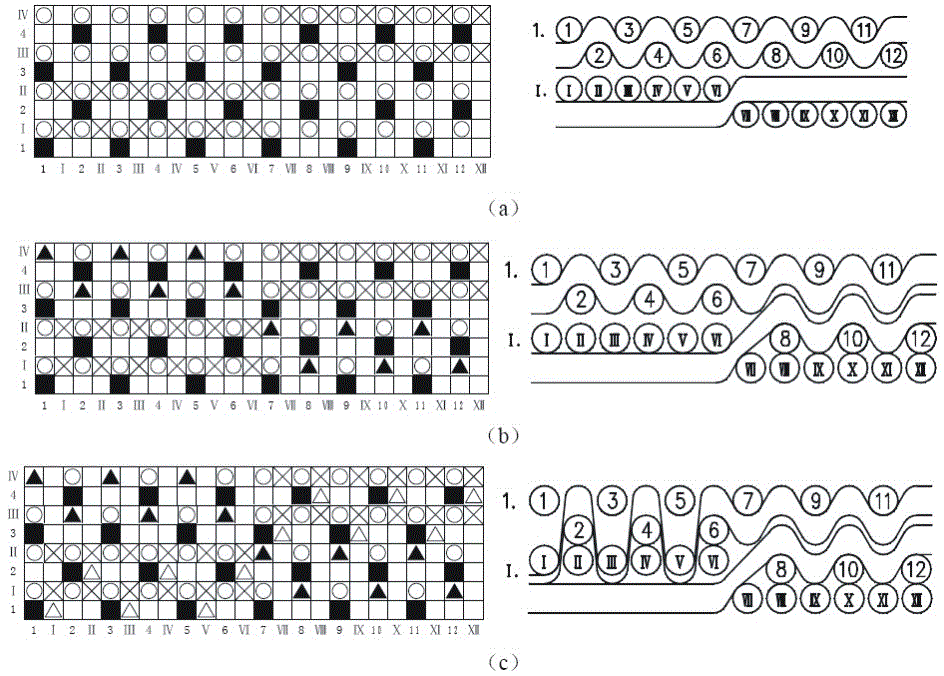

[0026] A moisture-wicking and quick-drying fabric, such as image 3 As shown in a, it is a double-layer weave, the surface layer is plain weave, the inner layer is puffy weave, and there is no connection between the surface layer and the inner layer. The surface and inner warp yarns are kapok / cotton blended yarns, and the weft yarns are made of coolmax yarns.

Embodiment 2

[0028] A moisture-wicking and quick-drying fabric, such as image 3 As shown in b, it is a double-layer weave, the surface layer is a plain weave, the inner layer is a puffy weave, and the surface layer and the inner layer are connected "top to bottom" (the surface warp and the inner weft are connected). The surface and inner warp yarns are kapok / cotton blended yarns, and the weft yarns are made of coolmax yarns.

Embodiment 3

[0030] A moisture-wicking and quick-drying fabric, such as image 3 As shown in c, it is a double-layer weave, the surface layer is plain weave, the inner layer is puffy weave, and the surface layer and the inner layer are jointed (the inner warp and the outer weft, and the outer warp and the inner weft are joined at the same time). The surface and inner warp yarns are kapok / cotton blended yarns, and the weft yarns are made of coolmax yarns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com