Sintered body, sintered permanent magnet and preparation method thereof

A technology of sintered body and permanent magnet, which is used in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of difficult control, complicated manufacturing methods and processes, and achieve the effect of improving diffusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081]

[0082] The preparation method of the sintered body comprises the following steps: (a) smelting raw materials of the sintered body to obtain master alloy flakes; (b) making the master alloy flakes into magnetic powder; (c) pressing the magnetic powder in a magnetic field, and then isostatic pressing (d) After the green body is subjected to the first vacuum heat treatment, the second vacuum heat treatment and the third vacuum heat treatment, a sintered body is obtained.

[0083] The sintered body prepared by the above method has Nd 2 Fe 14 The main phase of the B crystal phase and the grain boundary phase of the rare earth-rich phase. The raw materials of the sintered body are prepared according to the following relational formula: R a B b Ga c Cu d Al e m f co g Fe 余量 . The above-mentioned elements and atomic percentages are as described above, and will not be repeated here. The preparation process will inevitably introduce a small amount of oxygen, nitrog...

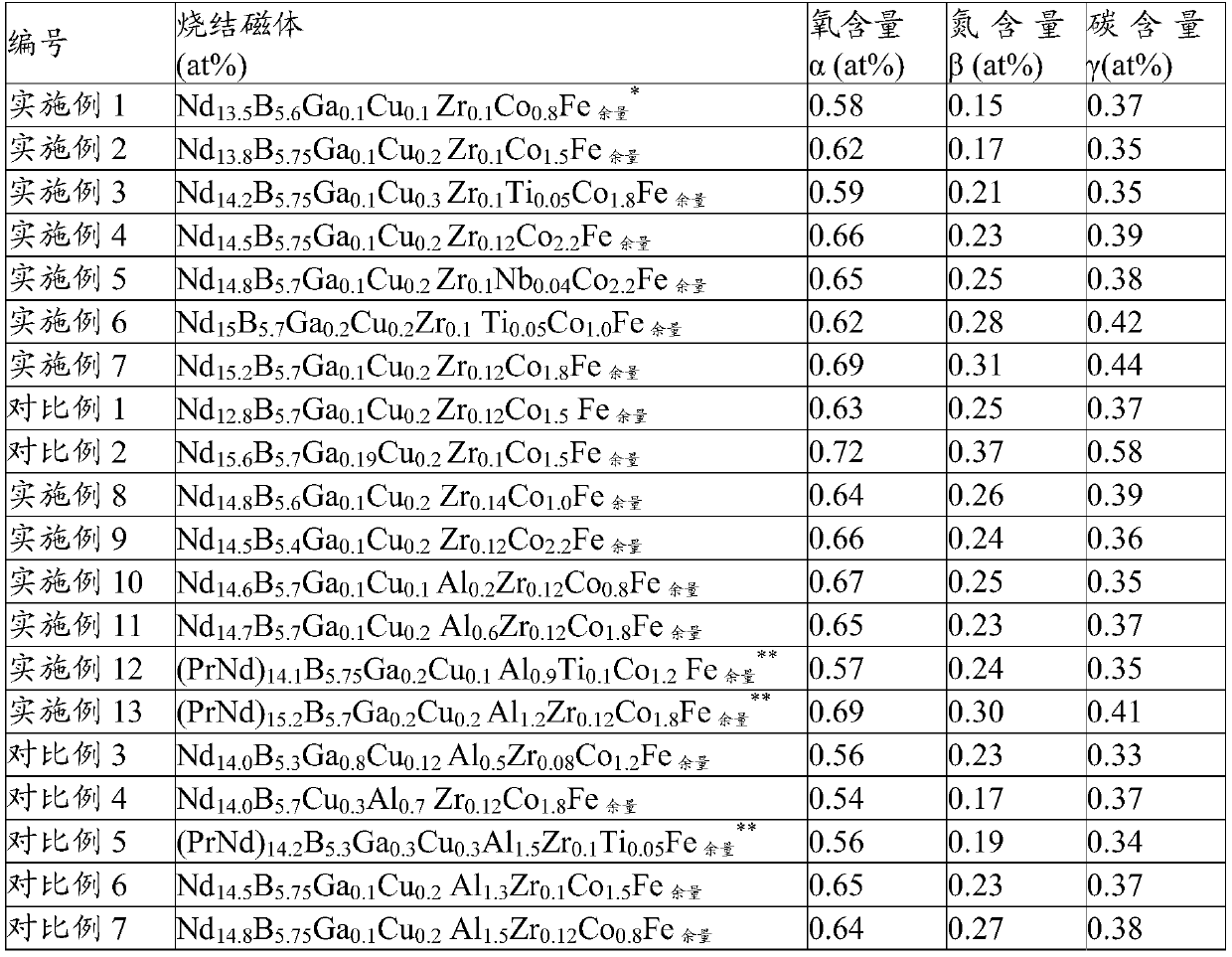

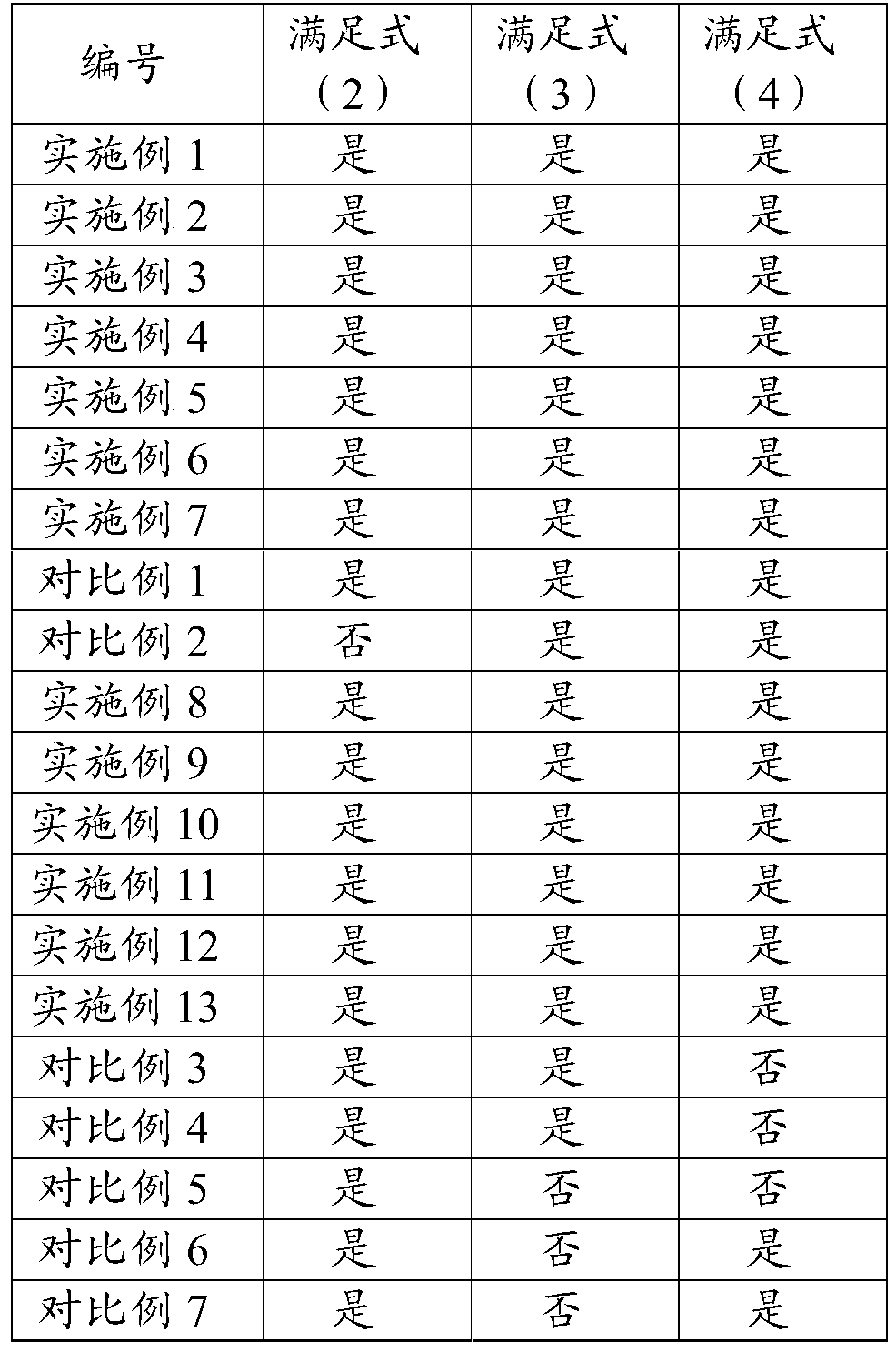

Embodiment 1~13

[0135] (1) Preparation of sintered body:

[0136] Prepare raw materials according to the formula in Table 1, and the formula meets the following condition A:

[0137] R a B b Ga c Cu d Al e m f co g Fe 余量 ; R contains at least one of Nd and Pr, and the ratio of La+Ce < 1.0at%, M contains at least one of Zr, Ti and Nb, a, b, c, d, e, f, g represent based on The atomic percentage of each element of all elements in the sintered body.

[0138] The sintered body is made by the following steps:

[0139] Smelting: Smelting the raw materials separately, so that the smelted raw materials are made into master alloy flakes, and the thickness of the master alloy flakes is 0.278mm;

[0140] Powder making: crush master alloy flakes into magnetic particles, and then grind the magnetic particles into magnetic powder (D50 is 3.8 μm, D90 / D10 is 3.8);

[0141] Molding: The magnetic powder is pressed to a density of 4g / cm under the action of an orientation magnetic field with a magneti...

Embodiment 14~16

[0161] The difference between Examples 14-16 and Example 6 is that: the sintered bodies obtained in the vacuum heat treatment step were cut into sintered bodies with thicknesses of 2 mm, 6 mm, and 8 mm, respectively. All the other conditions are the same as in Example 6. Specific steps are as follows:

[0162] (1) Preparation of sintered body:

[0163] Prepare raw materials by the formula (embodiment 6) of table 1. The sintered body is made by the following steps:

[0164] Smelting: Smelting the raw materials separately, so that the smelted raw materials are made into master alloy flakes, and the thickness of the master alloy flakes is 0.278mm;

[0165] Powder making: crush master alloy flakes into magnetic particles, and then grind the magnetic particles into magnetic powder (D50 is 3.8 μm, D90 / D10 is 3.8);

[0166] Molding: The magnetic powder is pressed to a density of 4g / cm under the action of an orientation magnetic field with a magnetic field strength of 2.0T 3 the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com