Method for improving magnetic properties of sintered neodymium-iron-boron thin-sheet magnet

A technology of NdFeB and magnetic properties, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem that the coercive force of sintered NdFeB thin sheet magnets does not increase significantly and affects the sintered NdFeB thin sheet magnets Squareness, rare earth metal powder instability and other problems, to achieve the effect of narrowing the content difference, easy operation, and improving the coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

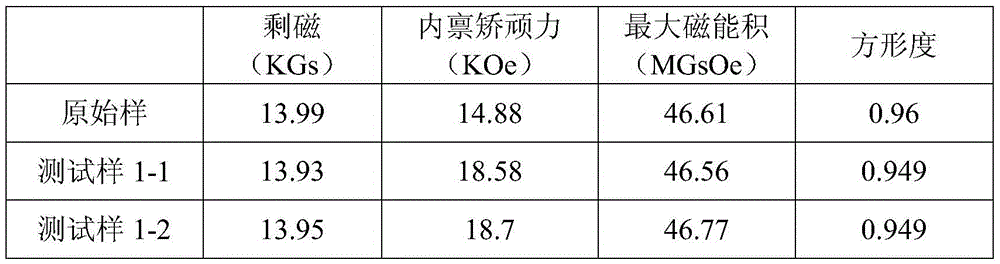

Embodiment 1

[0018] Embodiment 1: A method for improving the magnetic properties of sintered NdFeB thin-plate magnets, comprising the following steps:

[0019] ① Preparation of a suspension containing rare earth elements: the suspension containing rare earth elements is made of dysprosium oxide Dy 2 o 3 powder and calcium hydride CaH 2 The powder is uniformly dispersed in anhydrous ethanol after mixing, dysprosium oxide Dy 2 o 3 powder and calcium hydride CaH 2 The mass ratio of the powder is 3:1;

[0020] ② Evenly spray the suspension containing rare earth elements on the surface of the sintered NdFeB thin sheet magnet, and the sintered NdFeB thin sheet magnet has been surface pretreated before spraying;

[0021] ③Dry the sprayed sintered NdFeB flake magnets. The drying process is to keep warm at 60°C for 5 minutes, and store the sintered NdFeB flake magnets after drying in an inert gas environment;

[0022] ④ Put the dried sintered NdFeB sheet magnet at a pressure of 5×10 -4 In th...

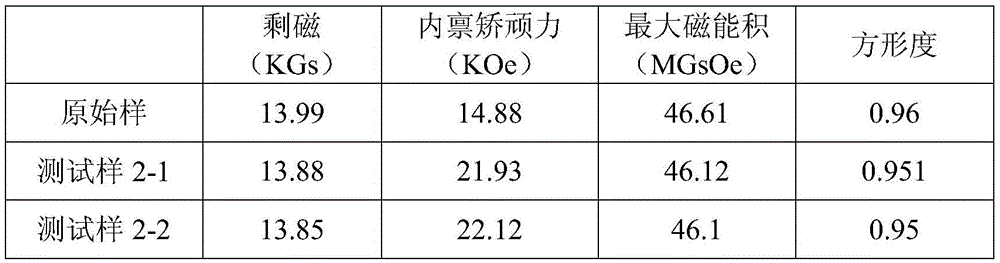

Embodiment 2

[0028] Embodiment 2: A method for improving the magnetic properties of sintered NdFeB flake magnets, comprising the following steps:

[0029] ① Preparation of a suspension containing rare earth elements: the suspension containing rare earth elements is made of terbium Tb oxide 2 o 3 powder and calcium hydride CaH 2 The powder is mixed and uniformly dispersed in absolute ethanol, and the terbium oxide Tb 2 o 3powder and calcium hydride CaH 2 The mass ratio of the powder is 3:1;

[0030] ② Evenly spray the suspension containing rare earth elements on the surface of the sintered NdFeB thin sheet magnet, and the sintered NdFeB thin sheet magnet has been surface pretreated before spraying;

[0031] ③Dry the sprayed sintered NdFeB flake magnets. The drying process is to keep warm at 60°C for 5 minutes, and the sintered NdFeB flake magnets after drying are stored in an inert gas environment;

[0032] ④ Put the dried sintered NdFeB sheet magnet at a pressure of 5×10 -4 In the v...

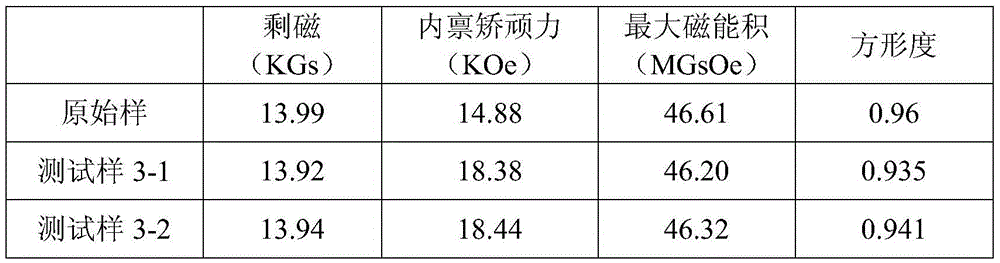

Embodiment 3

[0038] Embodiment three: a method for improving the magnetic performance of a sintered NdFeB thin slice magnet, comprising the following steps:

[0039] ① Preparation of a suspension containing rare earth elements: the suspension containing rare earth elements is made of dysprosium oxide Dy 2 o 3 powder and calcium hydride CaH 2 The powder is mixed and uniformly dispersed in absolute ethanol, and the terbium oxide Tb 2 o 3 powder and calcium hydride CaH 2 The mass ratio of the powder is 3:1;

[0040] ②Immerse the sintered NdFeB flake magnet in a suspension containing rare earth elements for ultrasonic treatment, and the surface of the sintered NdFeB flake magnet has been pretreated before immersion;

[0041] ③Dry the impregnated sintered NdFeB thin-slice magnets. The drying process is to keep warm at 60°C for 10 minutes, and store the dried sintered NdFeB thin-slice magnets in an inert gas environment;

[0042] ④ Put the dried sintered NdFeB sheet magnet at a pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com