Powder metallurgy method for preparing superfine crystalline alloy by use of micro-nano laminated sheet

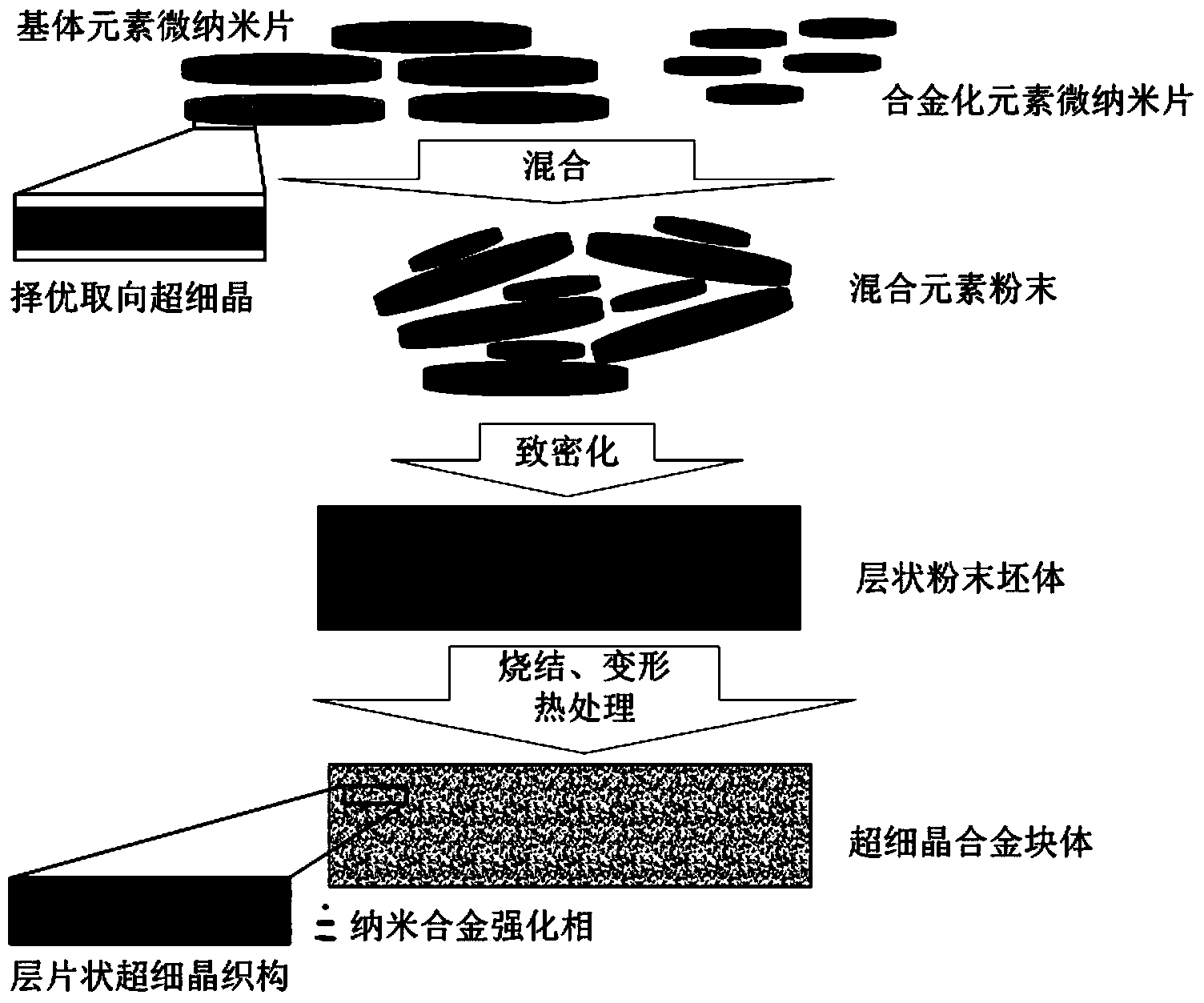

A powder metallurgy, micro-nano technology, applied in the field of powder metallurgy preparation, can solve the problems of restricting grain dislocation movement, sacrificial material plasticity, large particle size, etc., to achieve high plastic deformation ability, uniform and fine alloy strengthening phase, and diffusion The effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

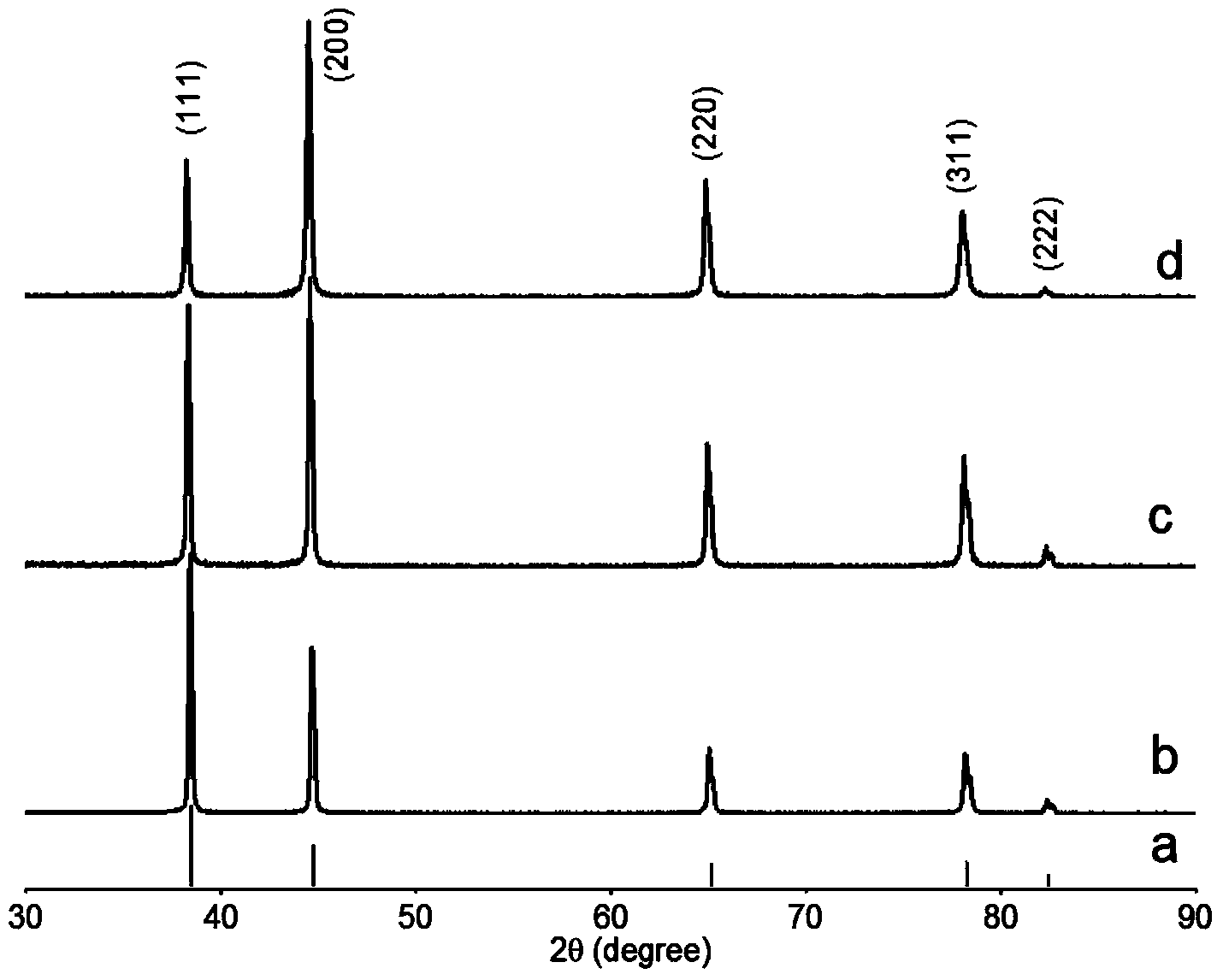

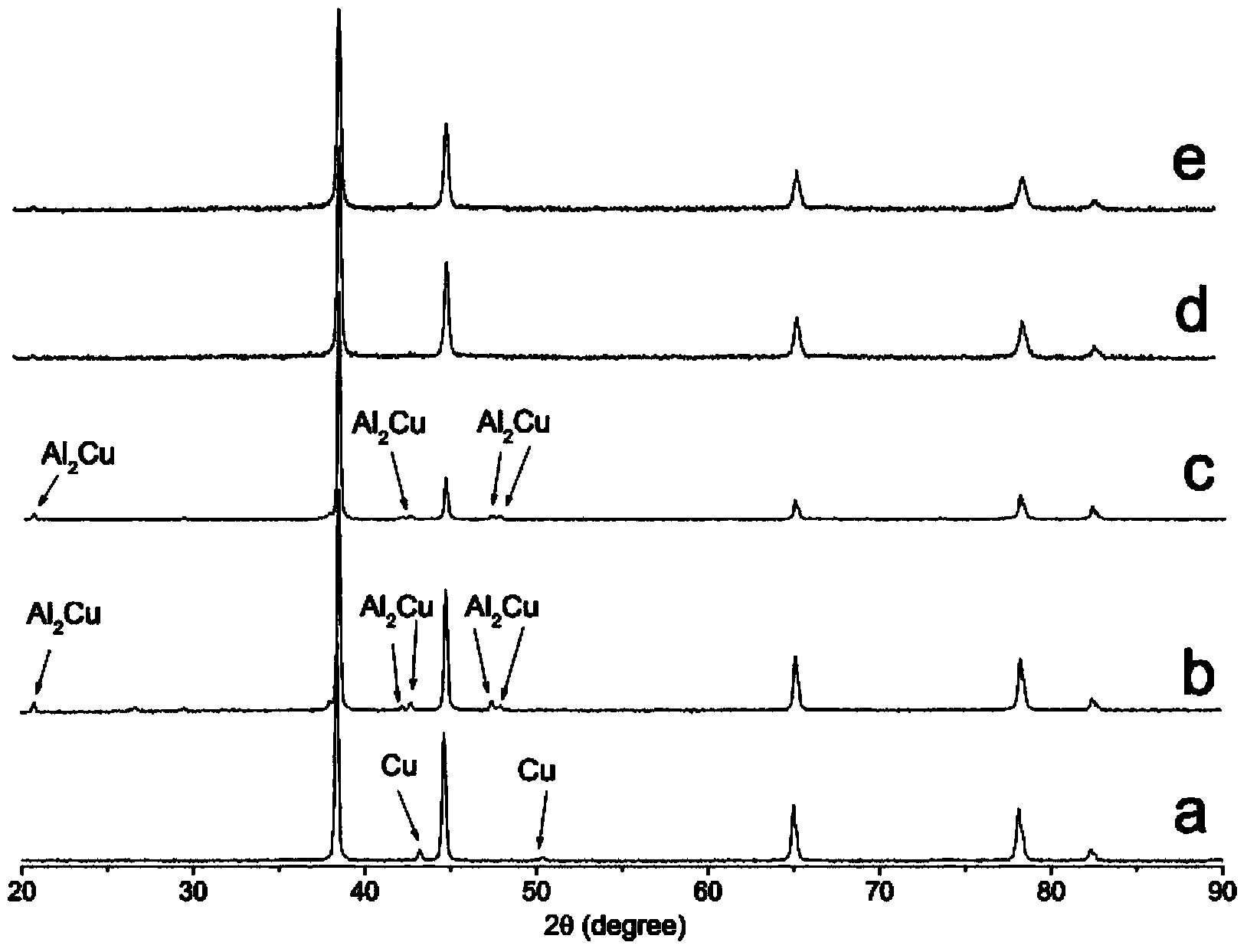

[0043] Take 100g of 10μm pure aluminum powder in a stirring ball mill, use absolute ethanol as a solvent, add 4g of titanate as a ball milling control agent, the ratio of ball to material is 20:1, and ball mill for 4 hours at a speed of 352 rpm to obtain flakes Aluminum powder, the sheet diameter is about 25μm, the sheet thickness is about 500nm, and the diameter-to-thickness ratio is about 50; take 50g of 40μm pure copper powder and place it in a planetary ball mill, use water as a solvent, add 4g of imidazoline as a ball mill control agent, ball The material ratio is 20:1, ball milled at 426 rpm for 10 hours to obtain flake copper powder with a diameter of about 5 μm, a thickness of about 500 nm, and an aspect ratio of about 10.

[0044] Put 96g of the above-mentioned flaky aluminum powder and 4g of flaky copper powder in absolute ethanol, stir and mix for 1h, filter and vacuum-dry to obtain mixed element powder, and finally press the mixed element powder under a pressure of ...

Embodiment 2

[0052] Take 100g of 10μm pure aluminum powder and place it in a stirring ball mill, use argon as a protective atmosphere, add 3g of stearic acid as a ball milling control agent, the ball-to-material ratio is 20:1, and ball mill for 6 hours at a speed of 423 rpm to obtain flakes The aluminum powder has a flake diameter of about 50 μm, a flake thickness of about 150 nm, and an aspect ratio greater than 300; the flake copper powder is prepared according to the method in Example 1.

[0053] Put 96g of the above-mentioned flake aluminum powder and 4g of copper powder flakes into a drum mixer and mix for 4 hours to obtain mixed element powder, and finally press the mixed element powder into a green body with a diameter of 40mm under a pressure of 100MPa. Next, the green body was sintered in an argon atmosphere at 580°C for 3h, and then kept in a vacuum extrusion furnace at 460°C for 1h, and then extruded into a 10mm-diameter tube with an extrusion ratio of 16:1 and an extrusion rate ...

Embodiment 3

[0058] Prepare flake aluminum powder according to the method for embodiment 1; Get 50g50 μm titanium powder and add 1g stearic acid and place in planetary ball mill as ball mill control agent, under the protection of argon, take stainless steel ball as ball mill medium, ball-to-material ratio is 20: 1. Ball mill at a speed of 426 rpm for 12 hours to obtain flake titanium powder with a diameter of about 10 μm, a thickness of about 300 nm, and an aspect ratio greater than 30.

[0059] Take 90g of the above-mentioned flake aluminum powder and 10g of flake titanium powder, mix them according to Example 2, then sinter the powder under vacuum hot pressing at 600°C and 100MPa for 5h to make a green body with a diameter of 40mm, and then put the sintered green body in the Hot forged at 400°C to about 10mm round cake, hot rolled at 350°C into a 3mm thick plate to obtain the final bulk Al-10Ti ultrafine grain alloy material. The mechanical properties of the material at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com