Co3O4/C lithium ion battery cathode material and preparation method thereof

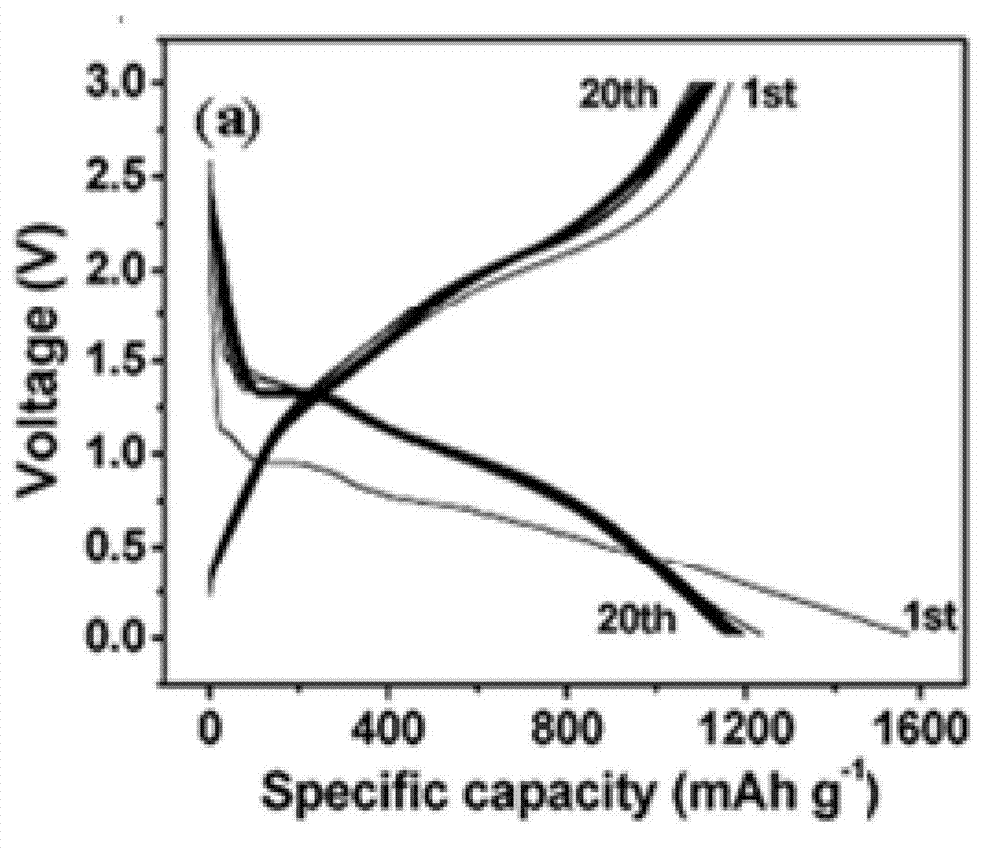

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of porous and hollow metal oxide-based nanocomposites with few simple and effective methods, high electrolyte selectivity, and inconvenient mass production Production and other issues, to achieve the effect of good charge and discharge rate performance, stable cycle performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

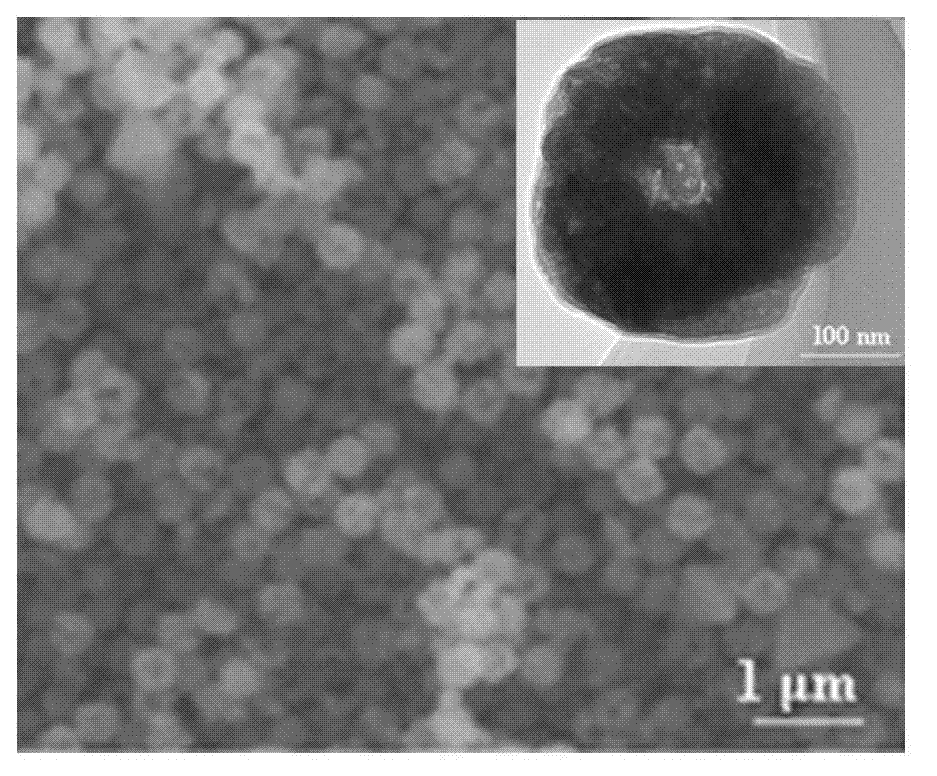

Embodiment 1

[0033] (1) Dissolve cobalt nitrate hexahydrate and glucose with a mass ratio of 10-20:1 in a mixture of 25 mL of ethanol and distilled water (the mass ratio of ethanol:distilled water is 4:1), and stir for 1 hour;

[0034](2) Add 0.4g of PVP as a dispersant to the stirred solution, and stir until a clear solution is obtained;

[0035] (3) Transfer the clarified solution obtained in step (2) into a self-pressurized reaction kettle with a 40mL polytetrafluoroethylene liner, seal it, and then place the reaction kettle in a constant temperature drying oven at 220°C for 24 hours;

[0036] (4) After the reaction kettle in step (3) was naturally cooled to room temperature, the product in the reaction kettle was poured out, centrifuged, and washed alternately with pure ethanol and distilled water for 3 times, and dried at 60°C to obtain a powdery substance;

[0037] (5) Put the powder obtained in step (4) in a tube furnace, under the protection of a flowing inert nitrogen atmosphere, ...

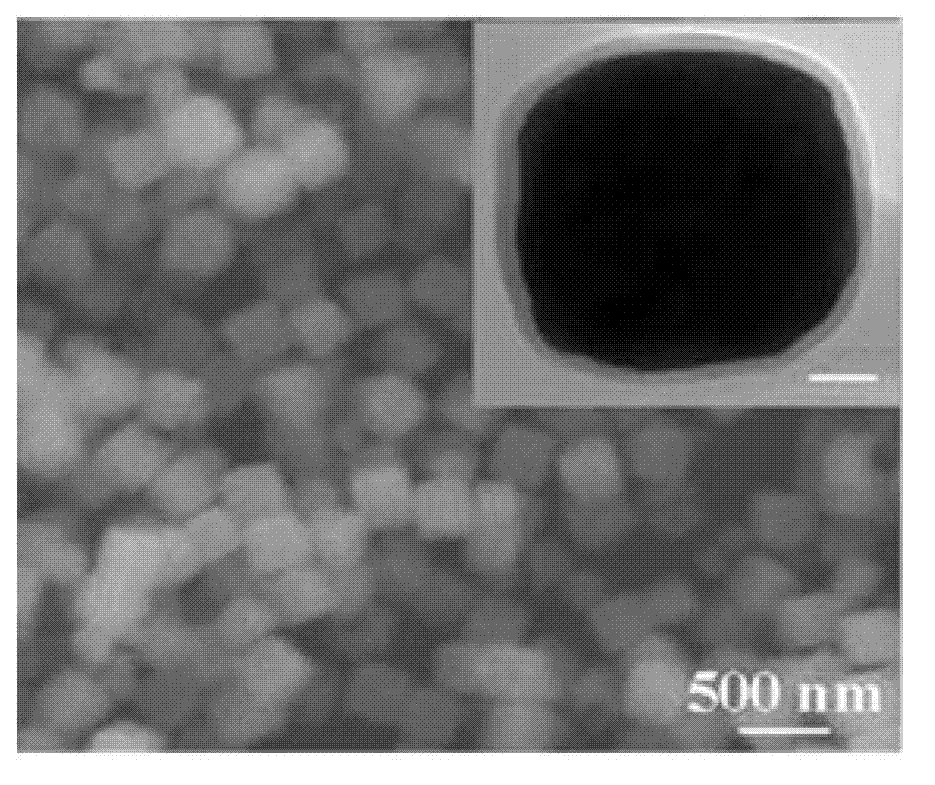

Embodiment 2

[0040] (1) Dissolve cobalt nitrate hexahydrate and glucose with a mass ratio of 10-20:1 in a mixture of 25 mL of ethanol and distilled water (the mass ratio of ethanol:distilled water is 4:1), and stir for 1 hour;

[0041] (2) Add 0.4g of PVP as a dispersant to the above stirred solution, and get a clear solution after stirring for a period of time;

[0042] (3) Transfer the clarified solution obtained in step (2) into a self-pressurized reactor with a polytetrafluoroethylene liner of 40 mL, seal it, and then place the reactor in a 220° C. constant-temperature drying oven to insulate for 16 hours;

[0043] (4) After the reaction kettle in step (3) is naturally cooled to room temperature, the product in the reaction kettle is poured out, centrifuged, and washed with pure ethanol and distilled water for 3 times alternately, and dried at 60°C to obtain a powdery substance ;

[0044] (5) Place the powder obtained in step (4) in a tube furnace, under the protection of a flowing in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com