Preparation method of doped spherical nanoscale Ni(OH)2

A nano and spherical technology, applied in the field of preparing spherical doped nano-Ni2, can solve the problem of irregular shape of doped nano-Ni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

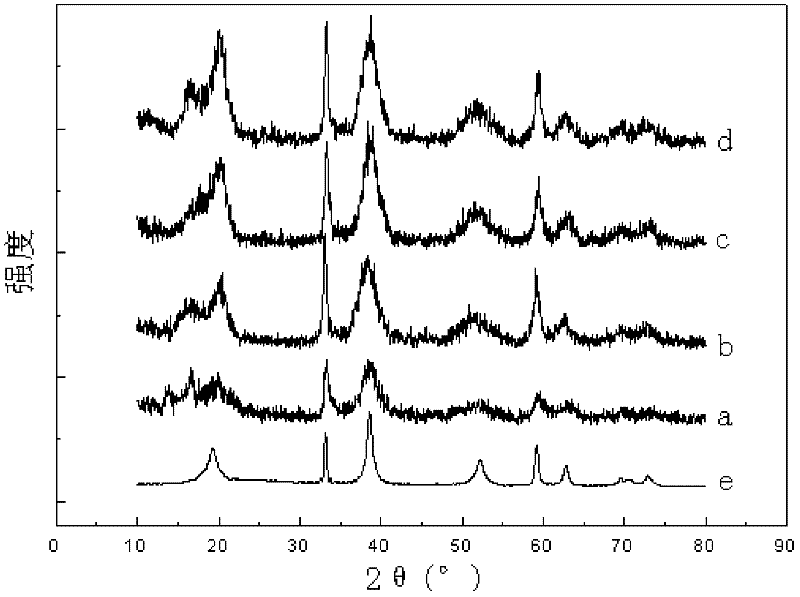

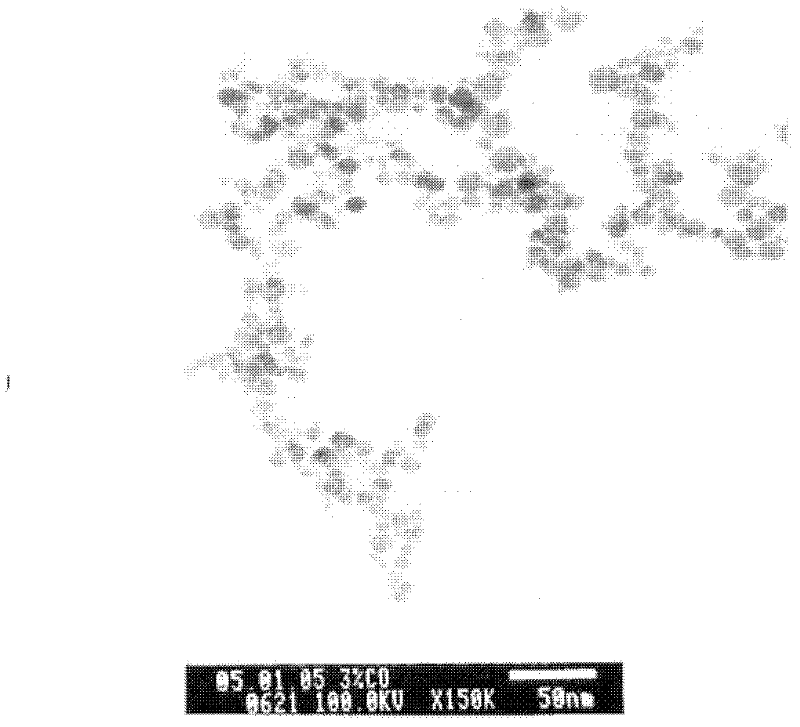

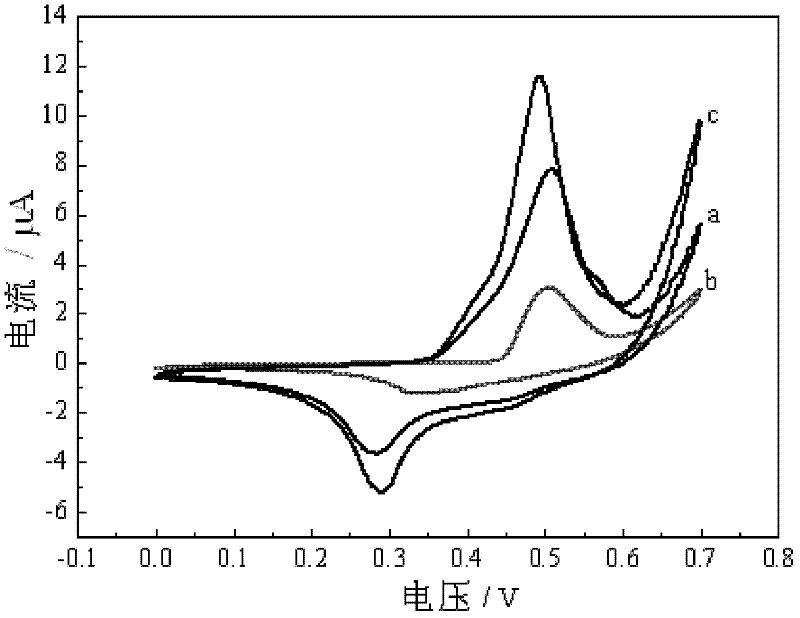

[0025] Specific implementation mode 1: This implementation mode is a spherical doped nano-Ni(OH) 2 The preparation method, it is realized by the following steps: one, by the mass ratio of n-hexanol and surfactant is the ratio of 2: 2~5, n-hexanol and surfactant are mixed to obtain mixed solution A, then to mixed solution Add alkanes or cycloalkanes to the mixture, and stir to obtain a mixed solution B, wherein the surfactant is octylphenyl polyoxyethylene ether, dioctyl sodium succinate and cetyltrimethylammonium bromide. One or a combination of several of them, the ratio of the volume of the added alkane or cycloalkane to the volume of the mixed solution A is 3 to 6:1, and the number of carbon atoms in the alkane or cycloalkane is 5 to 10; The solution C doped with metal ions and nickel ions is added to the mixed solution B obtained in step 1, and stirred to obtain a mixed solution D, wherein the doped metal ions are cobalt ions, zinc ions or aluminum ions, and the moles of d...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that the number of carbon atoms in the alkane or cycloalkane in Step 1 is 5-8. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 in that the number of carbon atoms in the alkane or cycloalkane in Step 1 is 6. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com