Preparation method of cyclic polymer and application of structured gel electrolyte based on polymer in solid sodium battery

A technology of cyclic polymers and gel electrolytes, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as lack of reports, achieve low cost, high electrochemical stability window, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

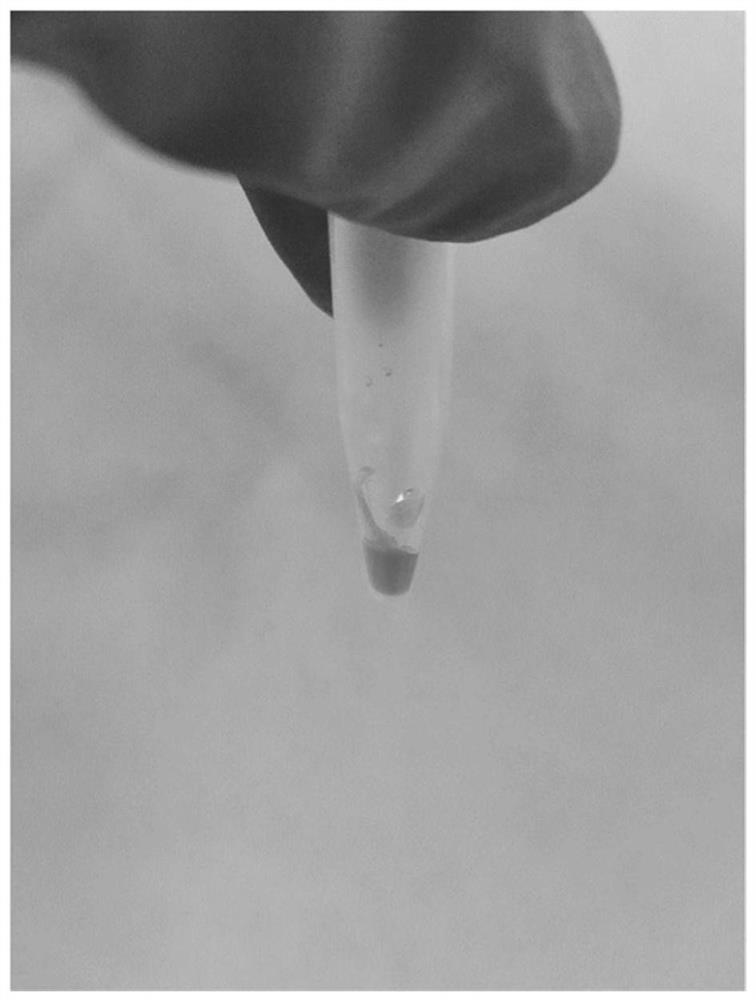

Image

Examples

preparation example Construction

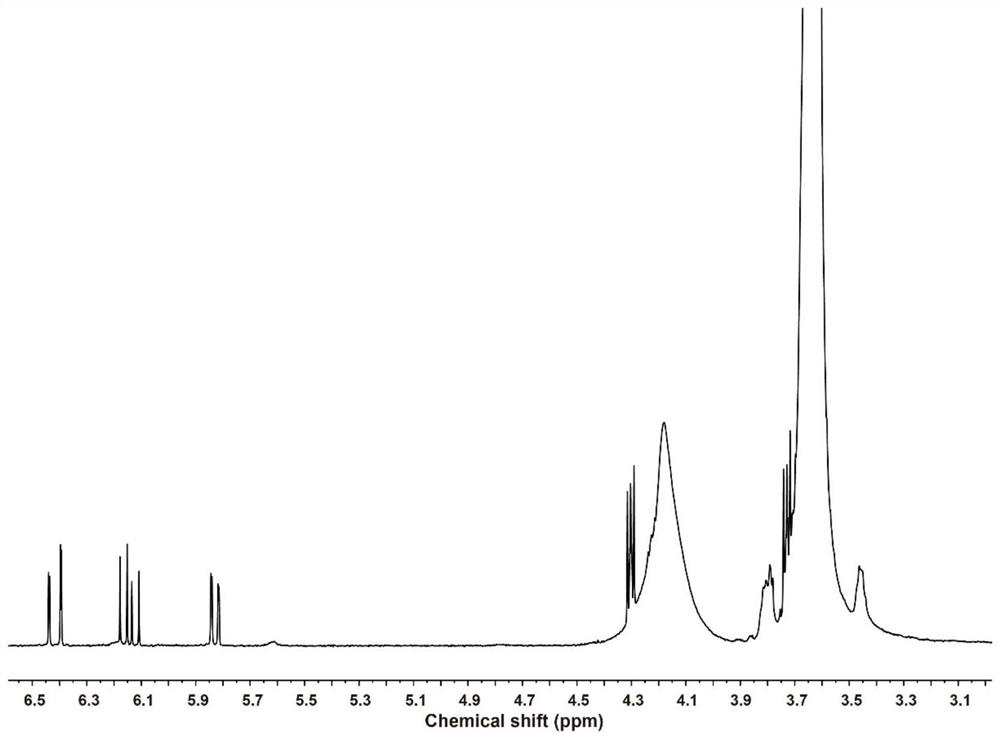

[0040] The invention discloses a preparation method of a structured gel electrolyte based on a cyclic polymer, which comprises the following steps:

[0041]1) A certain amount of initiator azobisisobutylcyanide (AIBN), chain transfer agent 4-cyano-4-(thiobenzoyl) valeric acid (CPADB), polyethylene glycol diacrylate (PEGDA ) monomers were added into a three-necked flask equipped with reaction solvent methyl ethyl ketone and fully dissolved by magnetic stirring, and the molar ratio of AIBN, CPADB and PEGDA was 1: (2-5): (100-1000);

[0042] 2) Deoxygenation by argon bubbling for 30 minutes;

[0043] 3) Submerge the three-neck flask into an oil bath preheated to 65°C to start the reaction, and the reaction is carried out under the protection of argon;

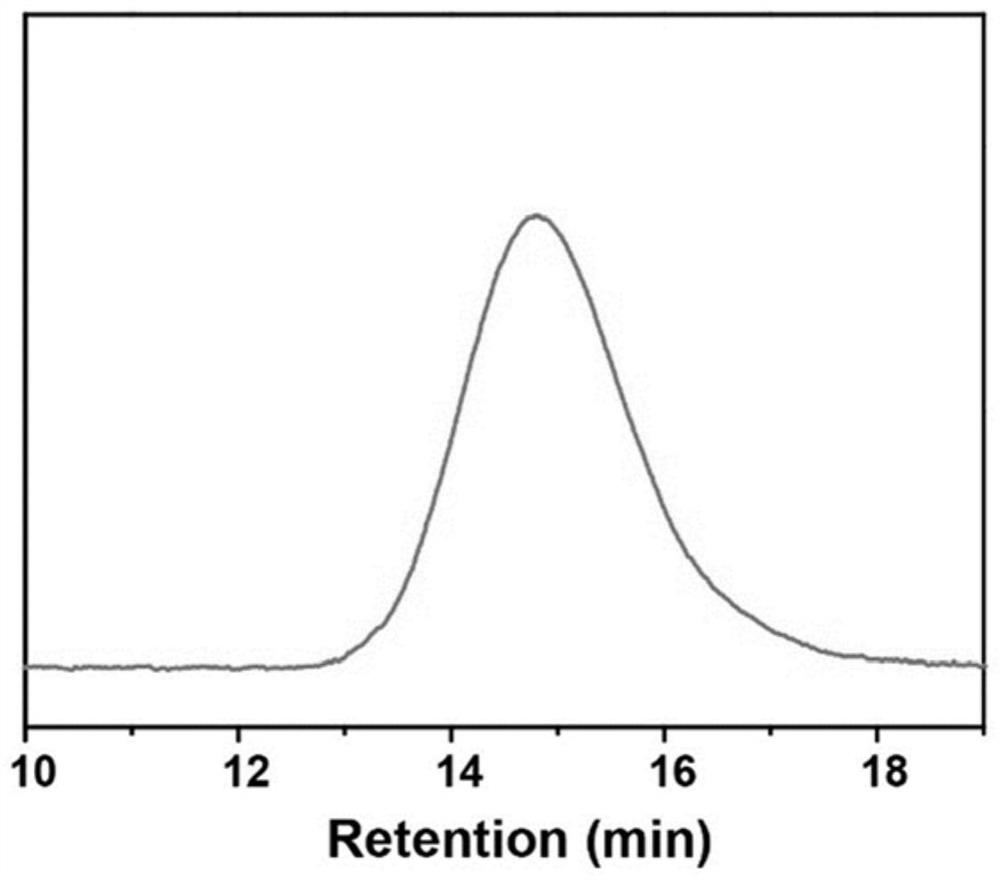

[0044] 4) Gel permeation chromatography is used to monitor the polymer molecular weight;

[0045] 5) When the molecular weight of the reaction is close to the set value of 17000-20000Da, stop the reaction and quench the free rad...

Embodiment 1

[0059] The feed ratio of initiator azobisisobutylcyanide (AIBN), chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) and polyethylene glycol diacrylate (PEGDA) is 1:5:1000, react at 65°C to obtain cyclic polyethylene glycol diacrylate (k-PEGDA) with a molecular weight of 17000Da. The obtained k-PEGDA is added into the liquid electrolyte, and the structured gel electrolyte is obtained through ultraviolet polymerization.

Embodiment 2

[0061] The feed ratio of initiator azobisisobutylcyanide (AIBN), chain transfer agent 4-cyano-4-(thiobenzoyl)valeric acid (CPADB) and polyethylene glycol diacrylate (PEGDA) is 1:5:250, reacted at 65°C to obtain cyclic polyethylene glycol diacrylate (k-PEGDA) with a molecular weight of 17000Da. The obtained k-PEGDA is added into the liquid electrolyte, and the structured gel electrolyte is obtained through ultraviolet polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com