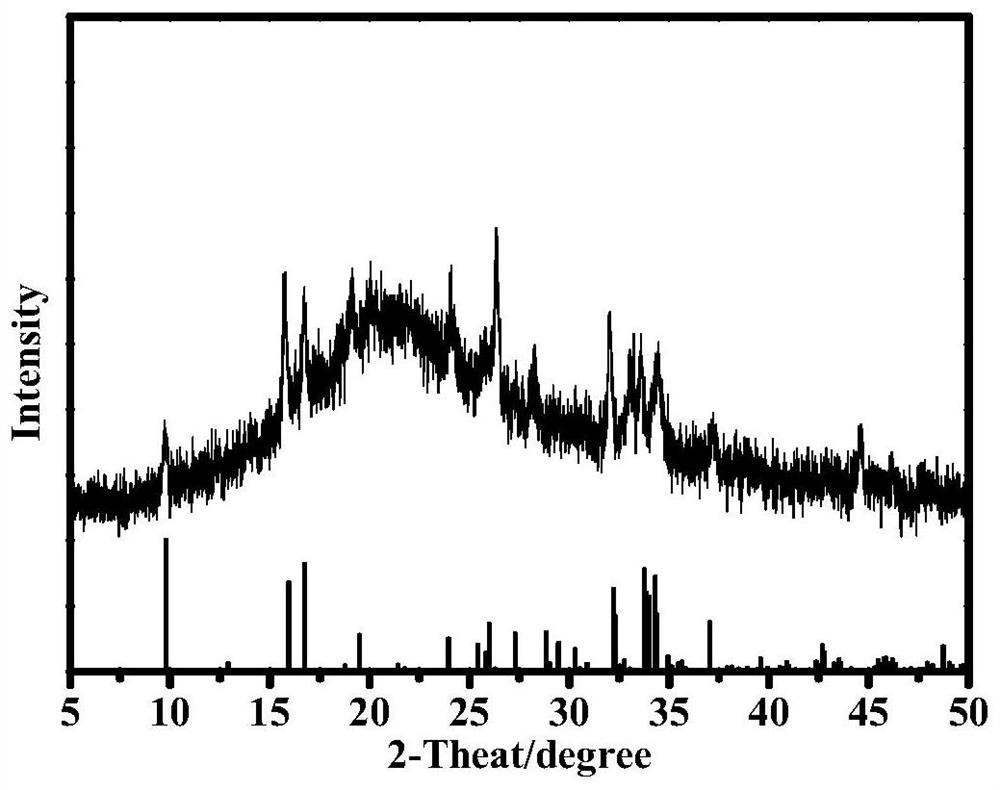

All-weather energy storage lamellar polyanionic compound positive electrode material and preparation method thereof

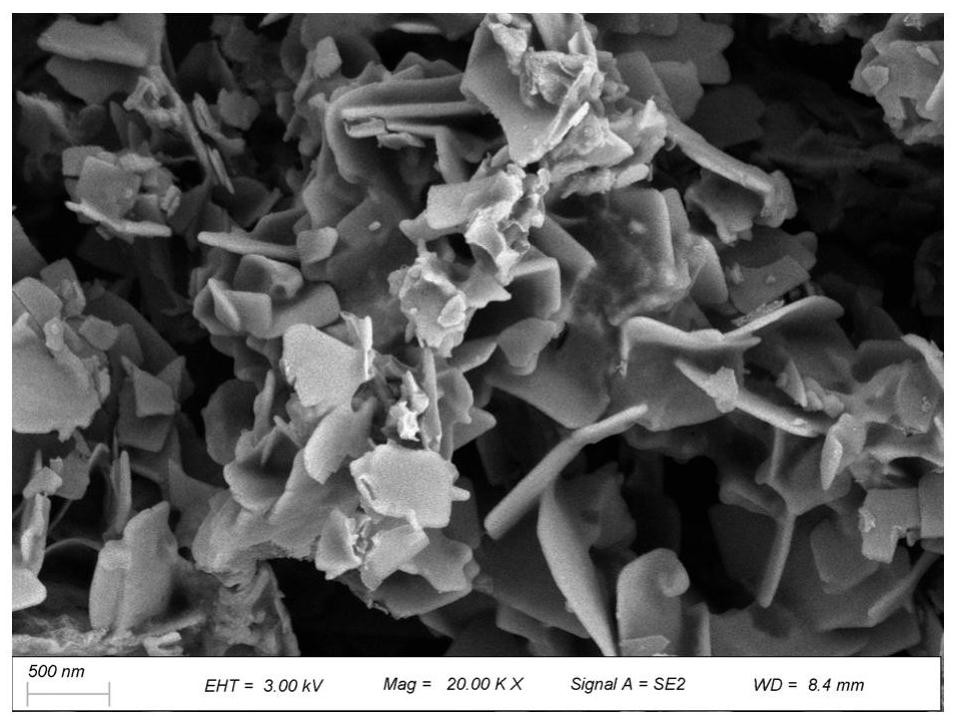

A polyanion and positive electrode material technology, applied in the direction of electrical components, battery electrodes, structural parts, etc., to achieve the effects of enhanced long-term cycle stability, large specific surface area, and short diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the all-weather energy storage sheet layered polyanion compound positive electrode material among the present invention comprises the following steps:

[0024] Step 1, adding diammonium hydrogen phosphate and oleic acid into a ball mill jar, and ball milling at a speed of 750 r / min for 20 minutes to obtain a first mixture. Among them, the excess of diammonium hydrogen phosphate is 2%-4% on the basis of theoretical materials used, which can be calculated according to the ratio of stoichiometric numbers.

[0025] Step 2, adding liquid paraffin or Span 80 to the first mixture and ball milling for 20 minutes to obtain the second mixture. Among them, the quality of liquid paraffin is twice that of oleic acid.

[0026] Step 3, adding ferric oxalate dihydrate into N-methylpyrrolidone for ultrasonic dispersion for 30 minutes to obtain a third mixture.

[0027] Step 4, adding the third mixture to the second mixture and ball milling for 20 minutes to o...

Embodiment 1

[0033] This embodiment prepares the all-weather energy storage sheet layered polyanion compound positive electrode material, and its specific preparation method includes the following steps:

[0034] Step 1: Add 2.3006g of diammonium hydrogen phosphate and 5.6429g of oleic acid into a ball mill jar, and ball mill for 20min at a speed of 750r / min to obtain the first mixture.

[0035] In step 2, 11.2984 g of liquid paraffin was added to the first mixture and ball milled for 20 minutes to obtain a second mixture.

[0036] Step 3, adding 2.6984 g of ferric oxalate dihydrate into 20 ml of N-methylpyrrolidone for ultrasonic dispersion for 30 min to obtain a third mixture.

[0037] Step 4, adding the third mixture to the second mixture and ball milling for 20 minutes to obtain the fourth mixture.

[0038] Step 5, adding 1.0599 g of anhydrous sodium carbonate to the fourth mixture and continuing ball milling for 12 hours to obtain a precursor.

[0039] Step 6: Put the precursor in a...

Embodiment 2

[0054] The preparation method of this example is basically the same as that of Example 1, except that the liquid paraffin in step 2 of Example 1 is replaced by Span 80 in the preparation method of this example.

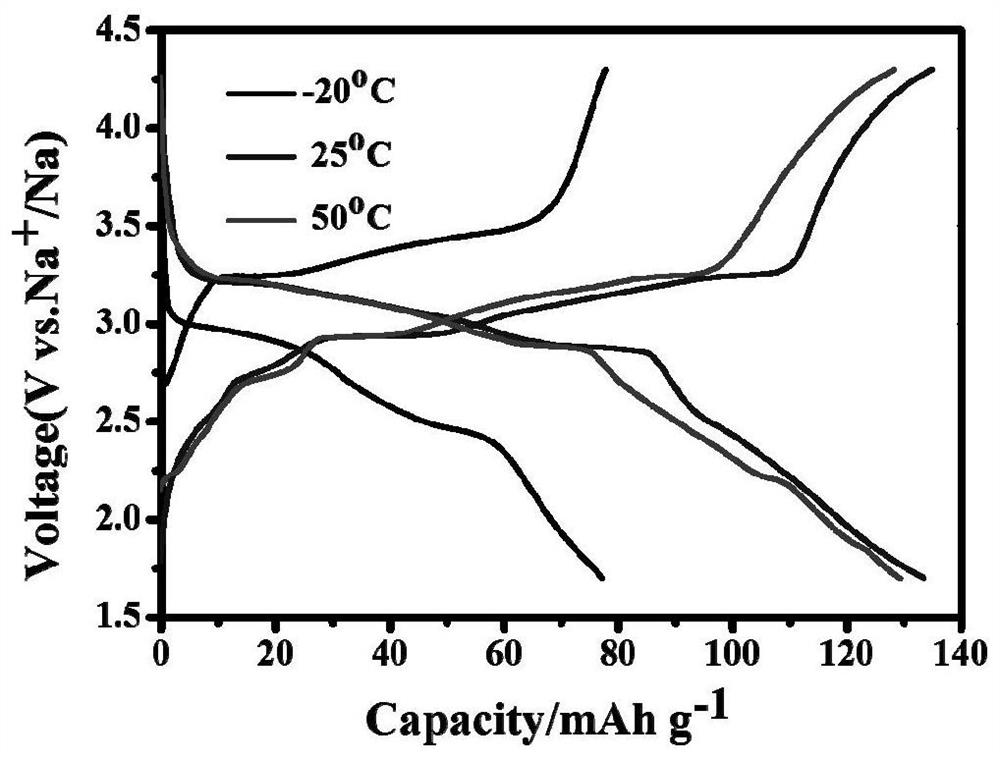

[0055] The modified sodium ion battery Na obtained in this embodiment 4 Fe 3 (PO 4 ) 2 (P 2 o 7 ) After the positive electrode material was directly packed into a button cell and carried out electrochemical tests, the same effect and effect as in Example 1 were achieved, and it had a higher reversible capacity under all weather conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com