Anode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of sewage discharge, long production process, and increased cost, and achieve no waste discharge, low raw material and production costs, The effect of increasing the operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

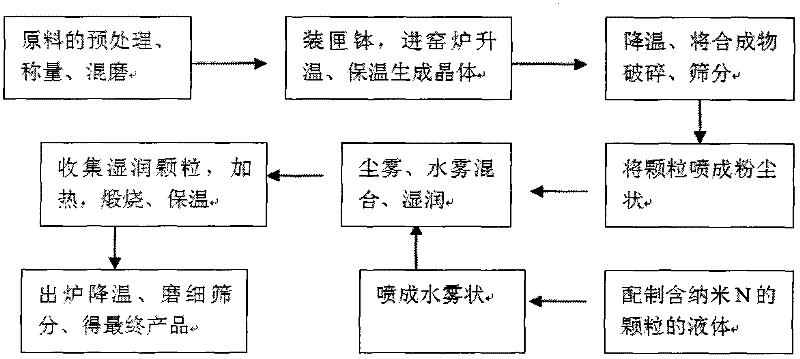

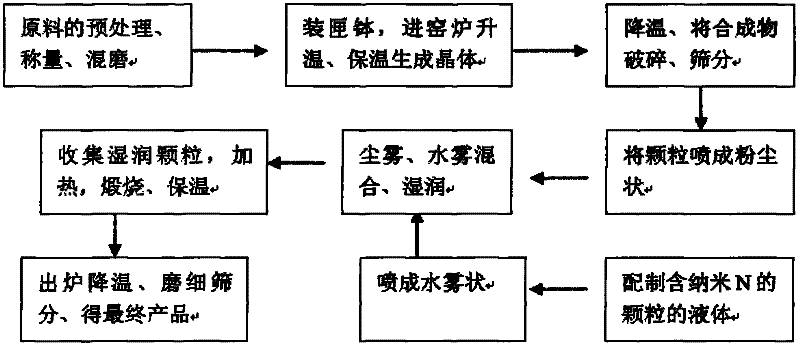

Method used

Image

Examples

Embodiment 1

[0035] (1) Take by weighing the reactant raw material lithium carbonate, manganese carbonate, aluminum hydroxide, magnesium carbonate with higher purity in the ratio of 1.01: 1.9: 0.1: 0.05 by the ratio of molar fractions of Li: Mn: Al: Mg, will weigh The measured lithium carbonate, manganese carbonate and aluminum hydroxide are mixed and milled; the weighed magnesium carbonate is used for later use;

[0036](2) Using the heating device of the electric heating tunnel heating furnace, put the mixed and ground mixture raw materials into a flat-bottomed ceramic bowl, and fill it with two-thirds of the capacity of the bowl, level the surface of the mixture, do not pile up the tip, and install the raw materials The ceramic flat-bottomed bowl is sent into the tunnel heating furnace for heating through the porcelain roller, and the air atmosphere is heated at a heating rate of 20°C / min. When the temperature reaches 800°C, it is kept for 15 hours;

[0037] (3) The ceramic flat-bottome...

Embodiment 2

[0045] (1) Take by weighing the higher reactant raw material lithium carbonate, manganese carbonate, aluminum hydroxide, zinc nitrate with the ratio of 1.03: 1.85: 0.15: 0.05 by the mole fraction ratio of Li: Mn: Al: Zn, will weigh The measured lithium carbonate, manganese carbonate and aluminum hydroxide are mixed and mixed; the weighed zinc nitrate is set aside;

[0046] (2) Using the heating device of the electric heating tunnel heating furnace, put the mixed and ground mixture raw materials into a flat-bottomed ceramic bowl, and fill it with two-thirds of the capacity of the bowl, level the surface of the mixture, do not pile up the tip, and install the raw materials The ceramic flat-bottomed bowl is sent into the tunnel heating furnace for heating through the porcelain roller, and the air atmosphere is heated at a heating rate of 20°C / min. When the temperature reaches 800°C, it is kept for 18 hours;

[0047] (3) The ceramic flat-bottomed bowl in step (2) is withdrawn from...

Embodiment 3

[0055] (1) Take by weighing the higher purity reactant raw materials lithium carbonate, manganese dioxide, dichromium trioxide, aluminum hydroxide in the ratio of 1.02: 1.9: 0.1: 0.06 by the molar ratio of Li: Mn: Cr: Al 1. Mix and grind the weighed lithium carbonate, manganese dioxide, and chromium trioxide, and weigh the aluminum hydroxide for subsequent use;

[0056] (2) Using the heating device of the electric heating tunnel heating furnace, put the mixed and ground mixture raw materials into a flat-bottomed ceramic bowl, and fill it with two-thirds of the capacity of the bowl, level the surface of the mixture, do not pile up the tip, and install the raw materials The ceramic flat-bottomed bowl is sent into the tunnel heating furnace for heating through the porcelain roller, and the air atmosphere is heated at a heating rate of 5°C / min. When the temperature reaches 800°C, it is kept for 18 hours;

[0057] (3) The ceramic flat-bottomed bowl in step (2) is withdrawn from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com