Lithium secondary battery and preparation method thereof

A lithium secondary battery and lithium salt technology, applied in the field of lithium secondary batteries with good high-temperature performance and its preparation, can solve the problems of poor thermal stability and chemical stability, insufficient high-temperature performance of lithium secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

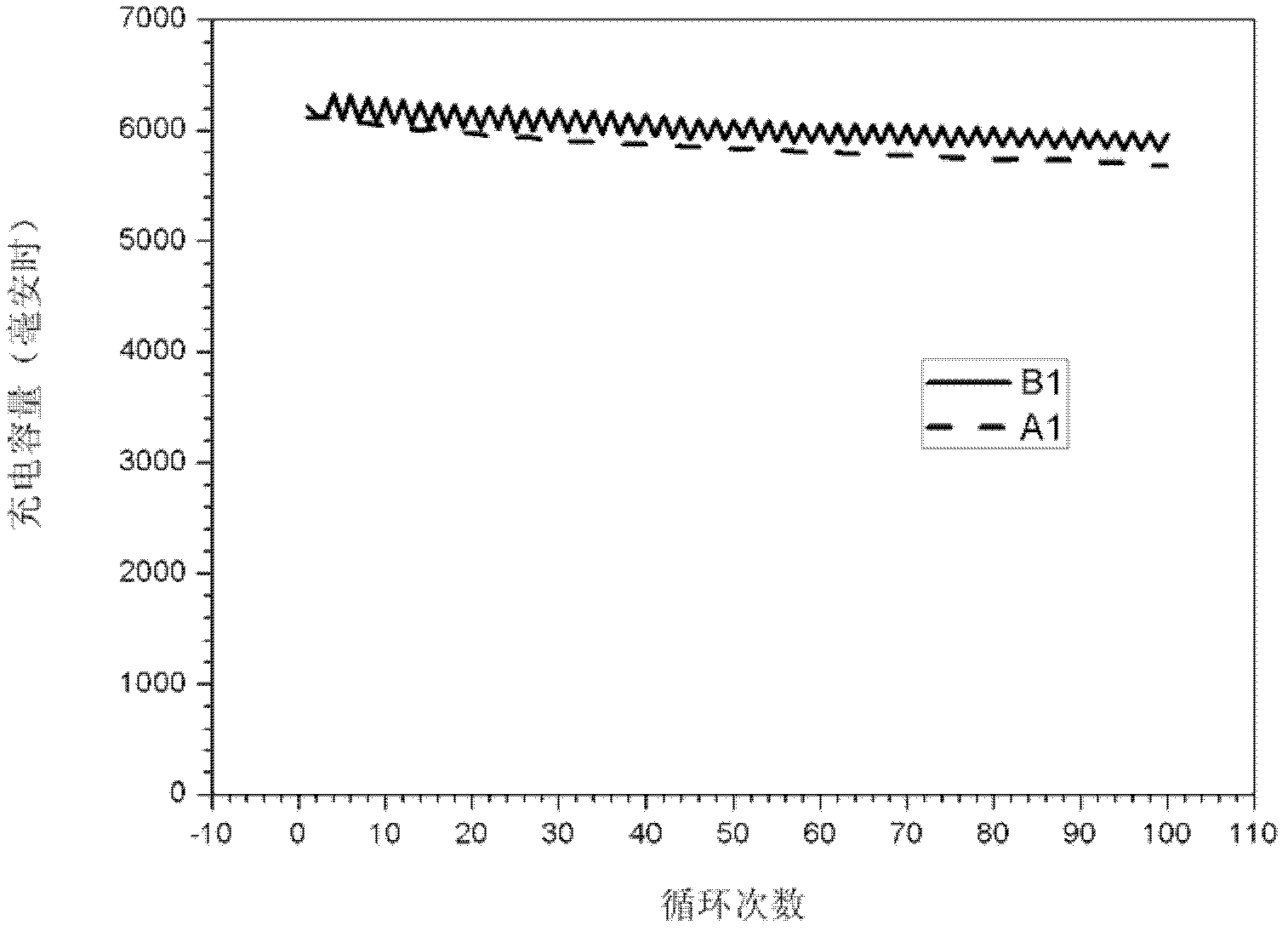

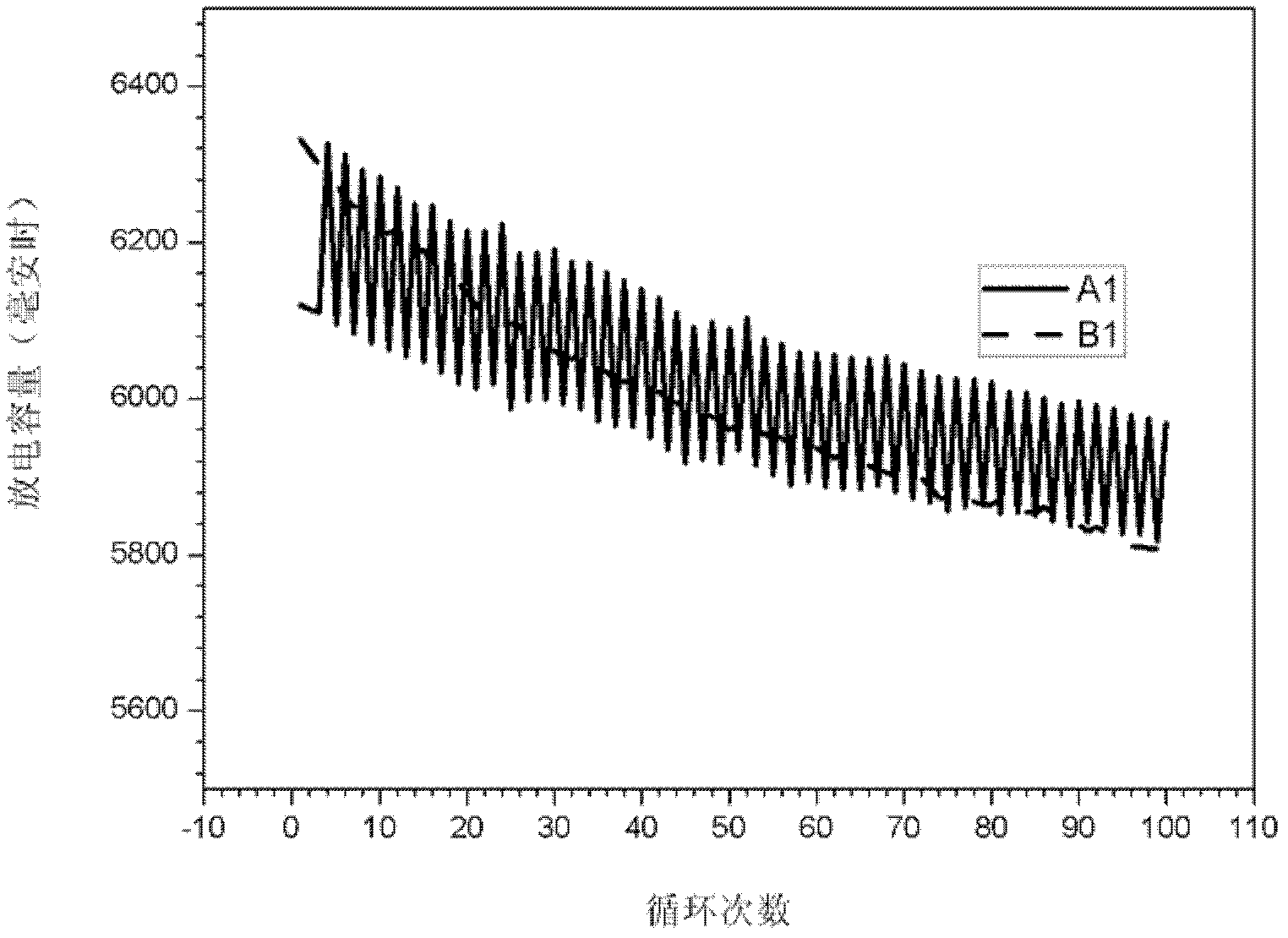

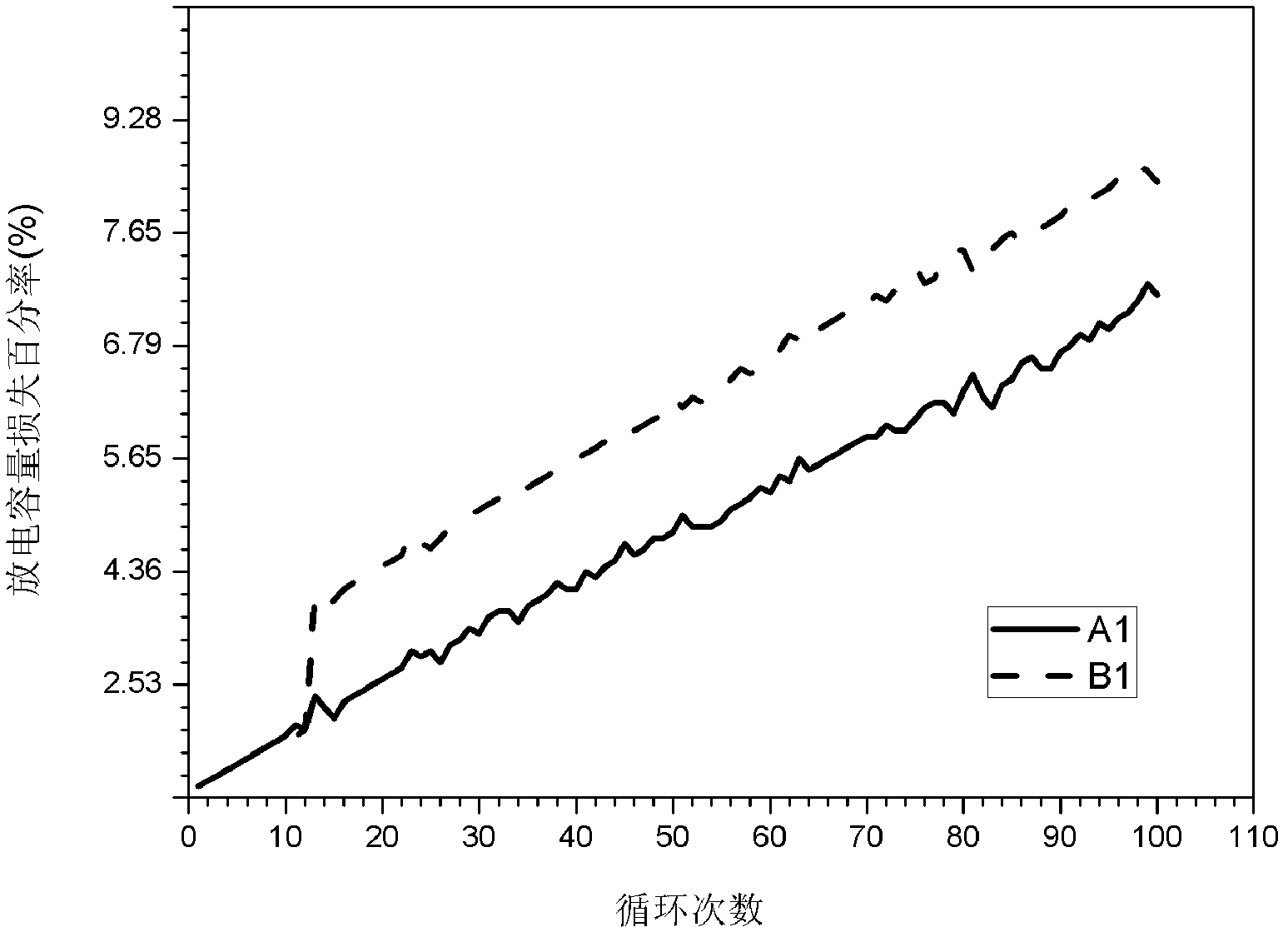

Embodiment 1

[0047] This embodiment is used to illustrate the non-aqueous electrolyte solution of the lithium secondary battery of the present invention and its preparation method.

[0048] At room temperature, in a glove box, dimethyl carbonate (DMC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) were mixed in a volume ratio of 5:2:3, and (fluorosulfonate Acyl)(perfluorobutylsulfonyl)imide lithium (LiFNFSI) (purchased from Suzhou Fluorite Battery Material Co., Ltd.), stir evenly, and configure the concentration of (fluorosulfonyl)(perfluorobutylsulfonyl)imide lithium A solution of 1 mol / L is the non-aqueous electrolyte of the lithium secondary battery of the present invention. For convenience of description, this non-aqueous electrolytic solution is referred to as A1. The same below.

Embodiment 2、3

[0050] This embodiment is used to illustrate the non-aqueous electrolyte solution of the lithium secondary battery of the present invention and its preparation method.

[0051] The preparation steps of Examples 2 and 3 are the same as in Example 1, except that the content of lithium (fluorosulfonyl) (perfluorobutylsulfonyl)imide accounts for 0.01wt% and 50wt% of the total weight of the non-aqueous electrolyte, respectively %, and the prepared non-aqueous electrolytic solutions are denoted as A2 and A3 respectively.

Embodiment 4

[0053] This embodiment is used to illustrate the non-aqueous electrolyte solution of the lithium secondary battery of the present invention and its preparation method.

[0054]The preparation steps of this example are the same as those of Example 1, except that an SEI film-forming accelerator vinylene carbonate (VC) is added to the non-aqueous electrolyte A1, and the content of VC accounts for 1 wt% of the total weight of the electrolyte. The non-aqueous electrolytic solution of this example is referred to as A4. It should be noted that other feasible SEI film-forming accelerators can be used here, and other functional additives, such as anti-overcharge additives, flame retardants or stabilizers, can also be added at the same time to achieve corresponding improvement purposes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com