Cathode material for boracic lithium ion battery and preparation method thereof

A cathode material, ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the gram capacity and discharge voltage platform of the cathode material, and the improvement effect is limited, and achieve good battery electrochemical performance and capacity retention performance. , to avoid the effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

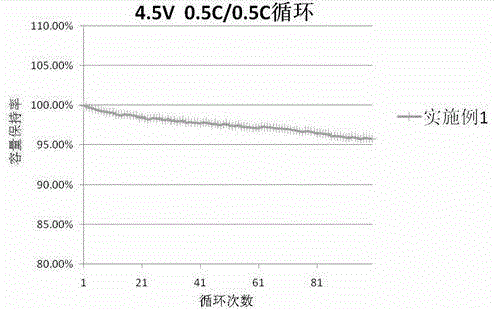

Embodiment 1

[0042] First, 5.0g of boric acid was dissolved in 250ml of water and added to the coating kettle; secondly, doped lithium cobaltate (molecular formula: LiCo 0.949 Zr 0.001 Mg 0.05 o 2 ) 1200g was added to the coating kettle, the stirring speed was 600r / min, and the stirring was even. Finally, 2.0 g of cerium nitrate was dissolved in 50 ml of water and added to the coating kettle. Turn on the heat and dry while stirring. Place the dried lithium cobaltate powder in a box furnace at a rate of 5°C / min to 700°C and keep it for 6 hours, then pass through a 300-mesh sieve after cooling down to room temperature in the furnace, and then the boron-containing inorganic high Molecular polymer coated lithium cobalt oxide powder. After the powder is mixed, pulped, coated, dried and rolled, assembled, liquid injected, statically formed and aged, the 4.5V half-cell 0.5C charge and discharge test is carried out to test the cycle performance of the material under high voltage; Conduct 1C ...

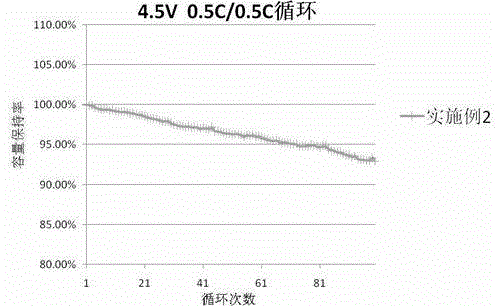

Embodiment 2

[0044] First, dissolve 15.0g of aluminum borate in 250ml of water and add it to the coating kettle; secondly, the ternary material with an average particle size of 12μm (molecular formula: LiNi 0.5 co 0.2 mn 0.3 o 2 ) 1000g was added to the coating kettle, the stirring speed was 500r / min, and the stirring was even. Finally, 2.0 g of lanthanum nitrate was dissolved in 80 ml of water and added to the coating kettle. Turn on the heat and dry while stirring. Put the dried ternary material powder in a box furnace at a rate of 5°C / min to 800°C and keep it for 6 hours, then pass through a 300-mesh sieve after cooling to room temperature with the furnace, and then the boron-containing inorganic high Molecular polymer coated lithium cobalt oxide powder. After the powder is mixed, pulped, coated, dried and rolled, assembled, liquid injected, statically formed and aged, the 4.5V half-cell 0.5C charge and discharge test is carried out to test the cycle performance of the material und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com