Gradient doped type lithium-ion cathode material and method for preparing same

A gradient doping and positive electrode material technology, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of lithium manganese oxide capacity attenuation and other problems, and achieve the solution of manganese dissolution, avoid surface coating is not tight, and improve the average valence state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

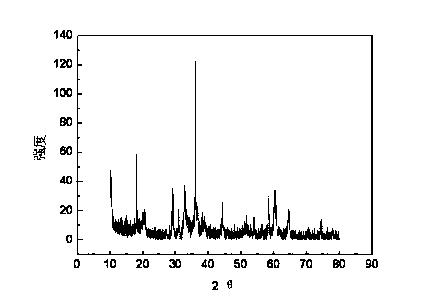

[0046] First prepare 20 L of 1 mol / L manganese sulfate solution and 10 L of 0.05 mol / L cobalt sulfate solution, and add the manganese sulfate solution into the reaction kettle at a flow rate of 1.5 L / h by using a peristaltic pump. At the same time, a peristaltic pump was used to add the cobalt sulfate solution to the manganese sulfate solution at a flow rate of 500ml / L. In the reactor, feed oxygen, and the oxygen flow rate is 25L / h. The reaction temperature was controlled at 60°C. During the oxidation process, 2mol / L ammonia water was used to control the pH of the reaction process to be 10.0. After the feeding is completed, oxygen is oxidized for 2 hours, and the filter residue obtained after filtering and washing is roasted at 450°C for 12 hours to obtain a cobalt-doped precursor. The chemical formula of the precursor is Mn 2.85 co 0.15 o 4 . From its XRD pattern ( figure 1 ) It can be seen that the structure of the spherical gradient doped precursor is similar to that...

Embodiment 2

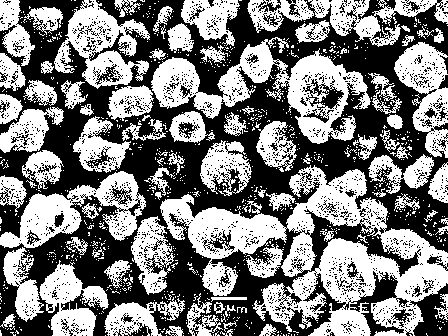

[0048] First prepare 20L of manganese sulfate of 2.5mol / L, 10L of 0.15mol / L nickel sulfate solution, adopt peristaltic pump to add manganese sulfate solution in the reaction kettle with the flow rate of 1.5L / h while adopting peristaltic pump with 500ml / L Nickel sulfate solution was added to manganese sulfate solution, air was passed through to oxidize, the oxidation temperature was controlled at 70°C, the oxygen flow rate was 30L / h, and 2mol / L ammonia water was used to control the pH of the reaction process to 9.0 during the oxidation process. After the feeding is completed, oxidize with oxygen for 2 hours, filter and wash the filter residue obtained by roasting at 650°C for 15 hours to obtain a nickel-doped precursor. The chemical formula of the precursor is Mn 2.85 Ni 0.15 o 4 . From the SEM image ( figure 2 ) It can be seen that the gradient doped nickel and cobalt precursors are spiral spherical, with uniform particle size distribution, and the particle size is 10-15 μ...

Embodiment 3

[0050] First prepare 20L of manganese sulfate of 3mol / L, cobalt sulfate and nickel sulfate molar ratio is 1:1, molar concentration is 0.2mol / L mixed solution 10L, adopts peristaltic pump to join manganese sulfate solution with the flow rate of 1L / h Adopt peristaltic pump to join in the manganese sulfate solution with 500ml / L cobalt sulfate and nickel sulfate mixed solution simultaneously in the reactor. Potassium permanganate was added into the reactor for oxidation, the oxidation temperature was controlled at 65°C, and the oxygen flow rate was 20L / h. During the oxidation process, 2mol / L ammonia water was used to control the pH of the reaction process to be 7.5. After the feeding is completed, oxygen is oxidized for 2 hours, and the filter residue obtained after filtering and washing is roasted at 900°C for 24 hours to obtain a nickel-doped and cobalt precursor. The chemical formula of the precursor is Mn 2.7 co 0.15 Ni 0.15 o 4 . Linear scanning of various elements of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com