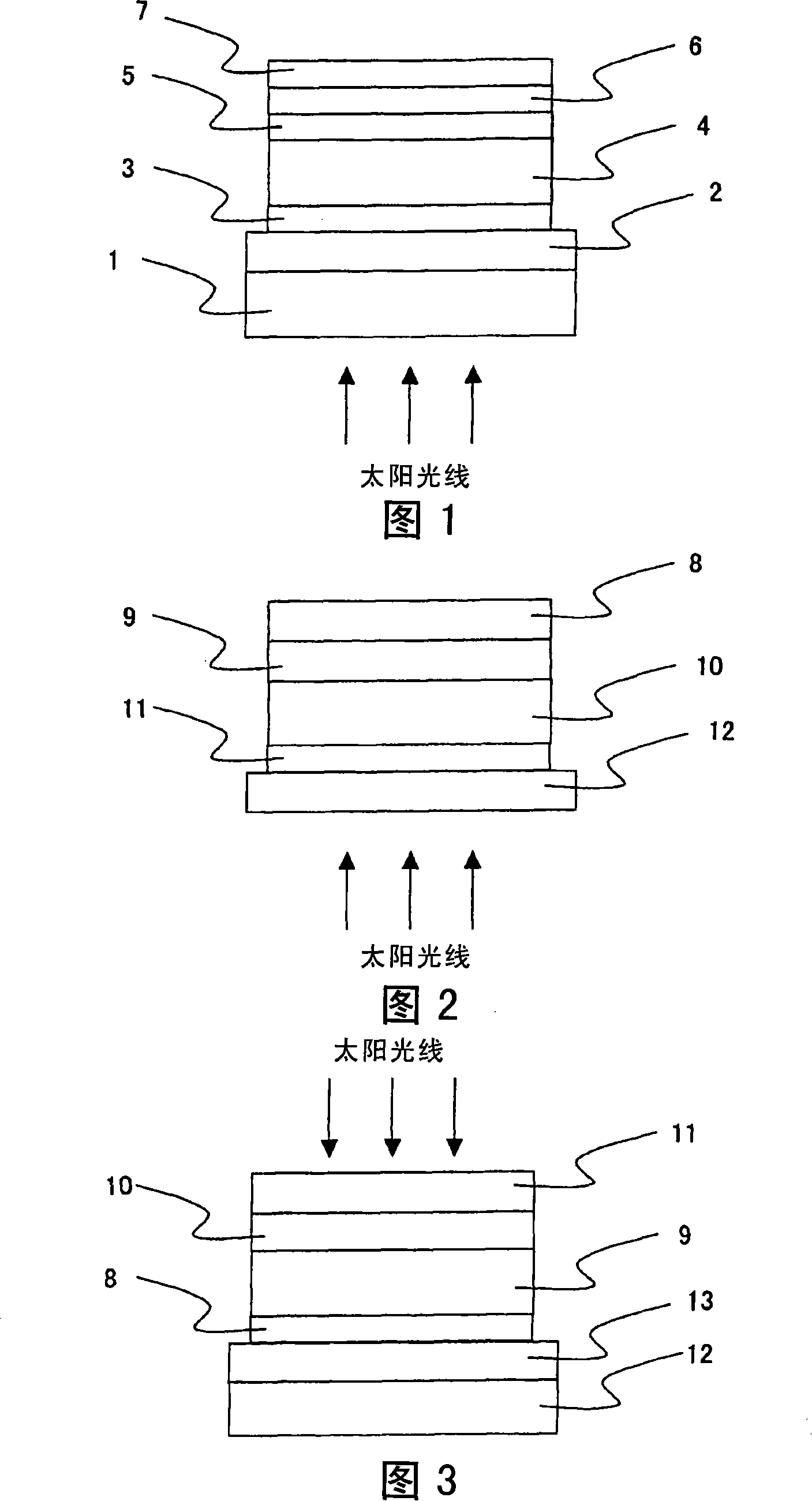

Oxide sintering body, its manufacturing method, transparent conductive film, and solar energy cell obtained by using the same

A transparent conductive film and solar cell technology, applied to the conductive layer on the insulating carrier, circuit, photovoltaic power generation, etc., can solve the problems of abnormal discharge disappearance, etc., and achieve high productivity, high energy conversion efficiency, and high transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

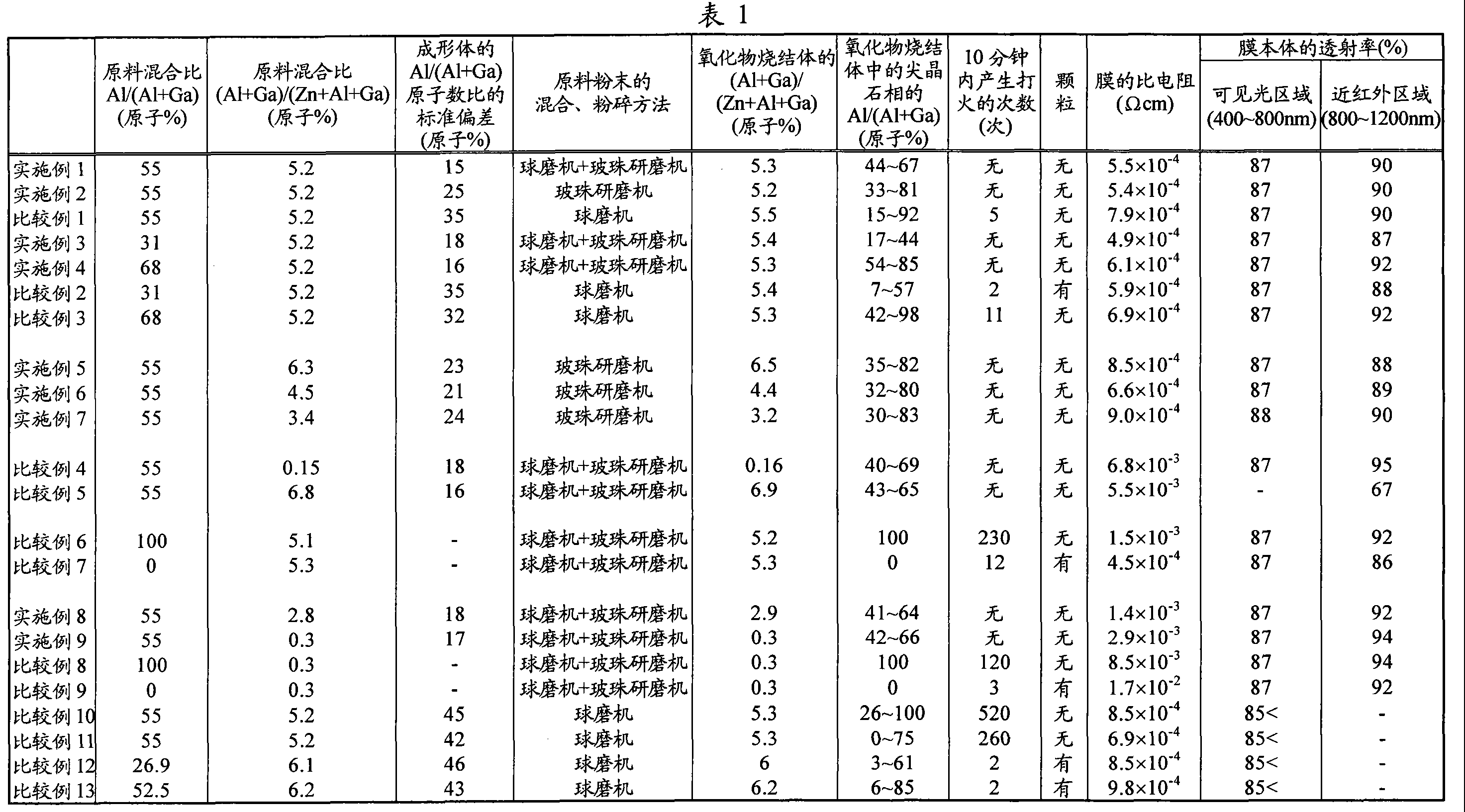

Embodiment 1

[0154]

[0155] An oxide sintered body containing zinc, aluminum, and gallium was produced as follows. As the starting material, use the respective average particle diameter of zinc oxide powder below 1 μm, and the average particle diameter of aluminum oxide powder below 1 μm, and the average particle diameter of gallium oxide powder below 1 μm, the proportion of raw materials according to Al / ( Al+Ga) was mixed so that the atomic ratio was 55 atomic %, and the (Al+Ga) / (Zn+Al+Ga) atomic ratio was 5.2 atomic %. The raw material powder is put into a resin tank together with water, and mixed by wet ball milling. At this time, using hard ZrO 2 balls with a mixing time of 18 hours. After ball milling and mixing, the slurry was taken out, and a dispersant and a binder of polyvinyl alcohol were added. The slurry was placed in a bead mill equipped with zirconia beads having a diameter of 3 mm for a double-pass treatment. The total processing time was 6 hours. The slurry was filt...

Embodiment 2

[0165] An oxide sintered body containing zinc, aluminum, and gallium was produced in the same manner and under the same conditions as in Example 1, except that the mixing pulverization treatment by ball milling of the raw material powder was not performed, and only the bead milling treatment was performed. That is, the types and proportions of raw material powders, bead grinding conditions, molding conditions, and firing conditions were the same as those in Example 1.

[0166] Using the molded body before firing in the same manner as in Example 1, the uniformity of the Al / (Al+Ga) atomic ratio of the mixed raw material powder was evaluated. As a result, the standard deviation σ was 25 atomic %, which was higher before firing. uniformity.

[0167] In addition, after firing, the obtained oxide sintered body was evaluated in the same manner as in Example 1. The end material of the obtained oxide sintered body was pulverized, powder X-ray diffraction measurement was carried out, a...

Embodiment 3

[0178] Except that the ratio of zinc oxide, aluminum oxide, and gallium oxide in the raw material powder is 31 atomic percent according to the Al / (Al+Ga) atomic number ratio, and the (Al+Ga) / (Zn+Al+Ga) atomic number ratio is 5.2 Except for setting the method of atomic %, in accordance with the same procedure and conditions as in Example 1, mixed pulverization treatment by ball milling and glass bead milling, molding and firing were performed to produce an oxide sintered body.

[0179] Using the molded body before firing in the same manner as in Example 1, the uniformity of the Al / (Al+Ga) atomic ratio of the mixed raw material powder was evaluated. As a result, the standard deviation σ was 18 atomic %, which was higher before firing. uniformity.

[0180] In addition, after firing, the obtained oxide sintered body was evaluated in the same manner as in Example 1. The end material of the obtained oxide sintered body was pulverized, powder X-ray diffraction measurement was carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com