Lithium manganese oxide spinel of anode materials of lithium ion batteries and method for manufacturing lithium manganese oxide spinel

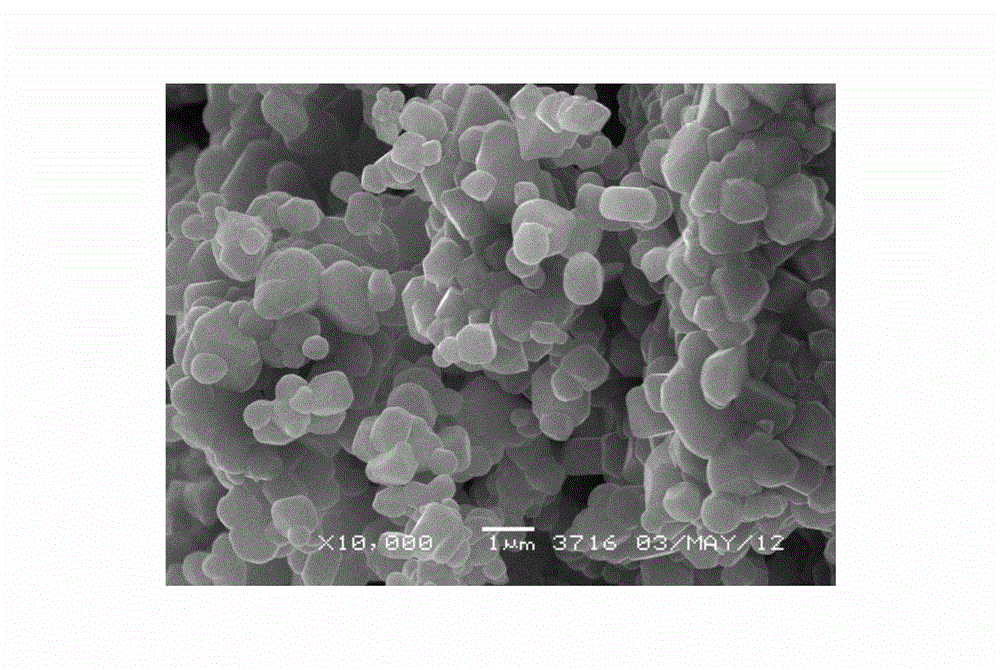

A technology of spinel lithium manganese oxide and lithium ion battery, which is applied in battery electrodes, manganate/permanganate, circuits, etc. It can solve the problem of low compaction density, restricting the development of lithium manganate, and primary particle size. Small and other problems, to achieve the maximum compaction density increase, promote the growth of primary particles, and achieve the effect of round and uniform primary particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

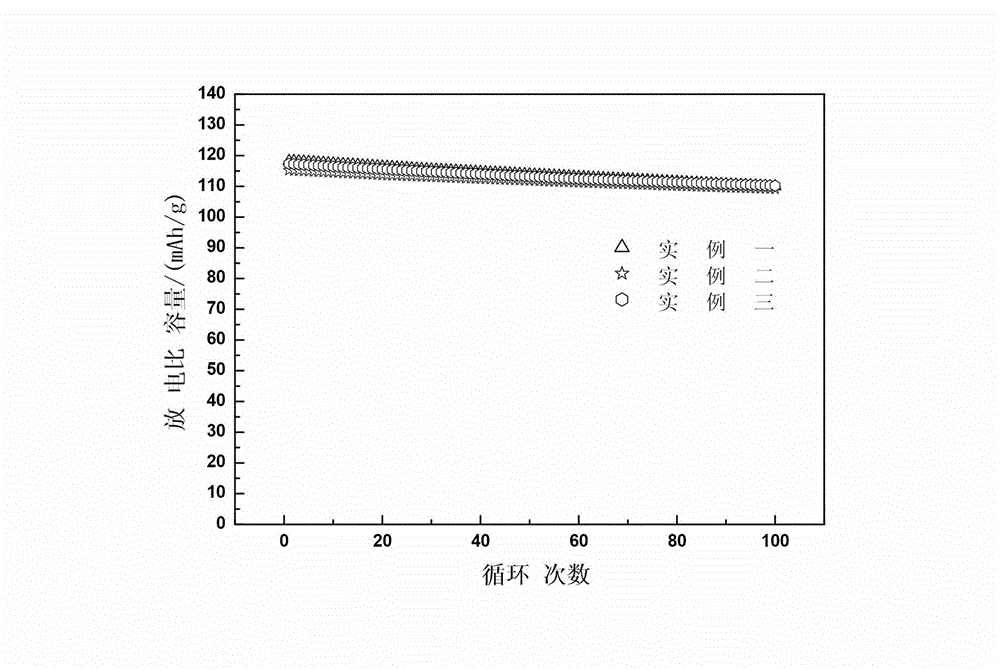

[0026] A kind of lithium ion battery cathode material spinel lithium manganate of the present invention, its molecular formula satisfies Li 1.00 mn 1.90 Al 0.04 co 0.03 La 0.03 o 4 , the specific surface area of the lithium manganate is 0.47m 2 / g, the total content of Na and K ion impurities is less than 800ppm, and the content of other impurities is less than 200ppm, and the maximum compacted density reaches 3.35g / cm 3 , The initial discharge capacity of the 0.1C button battery reaches 118.2mAh / g, and the 100-cycle cycle capacity decays by 7%.

[0027] The preparation method of the above-mentioned lithium ion battery cathode material spinel lithium manganese oxide in this embodiment comprises the following steps:

[0028] (1) Ingredients: lithium source Li 2 CO 3 , electrolytic manganese dioxide and doped metal additives are used as raw materials for batching, and the molar ratio of the total Li element, Mn element and doped metal element Me in the raw material is ...

Embodiment 2

[0036] A kind of lithium ion battery cathode material spinel lithium manganate of the present invention, its molecular formula satisfies Li 1.05 mn 1.85 al 0.07 Mg 0.05 Nb 0.03 o 4 , the specific surface area of the lithium manganate is 0.53m 2 / g, the total content of Na and K ion impurities is less than 800ppm, and the content of other impurities is less than 200ppm, and the maximum compacted density reaches 3.41g / cm 3 , The initial discharge capacity of the 0.1C button battery reaches 115.2mAh / g, and the 100-cycle cycle capacity decays by 5%.

[0037] The preparation method of the above-mentioned lithium ion battery cathode material spinel lithium manganese oxide in this embodiment comprises the following steps:

[0038] (1) Batching: Lithium source LiOH, electrolytic manganese dioxide and doped metal additives are used as raw materials for batching. When batching, the molar ratio of the total Li element, Mn element and doped metal element Me in the raw material sat...

Embodiment 3

[0046] A kind of lithium ion battery cathode material spinel lithium manganate of the present invention, its molecular formula satisfies Li 1.10 mn 1.80 Mg 0.07 al 0.06 Ti 0.05 Gd 0.02 o 4 , the specific surface area of the lithium manganate is 0.55m 2 / g, the total content of Na and K ion impurities is less than 800ppm, and the content of other impurities is less than 200ppm, and the maximum compacted density reaches 3.45g / cm 3 , The initial discharge capacity of the 0.1C button battery reaches 117.2mAh / g, and the 100-cycle cycle capacity decays by 6%.

[0047] The preparation method of the above-mentioned lithium ion battery cathode material spinel lithium manganese oxide in this embodiment comprises the following steps:

[0048] (1) Ingredients: lithium source Li 2 CO 3 , electrolytic manganese dioxide and doped metal additives are used as raw materials for batching, and the molar ratio of the total Li element, Mn element and doped metal element Me in the raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com