Preparation of spinel type Li-Mn-oxide lithium ion screening materials by hydrothermal method

A technology of lithium manganese oxide and lithium ions, which is applied in the direction of manganese compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of expensive metal organics, unfavorable large-scale production, harsh process conditions, etc., and achieve high selectivity, Uniform composition and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

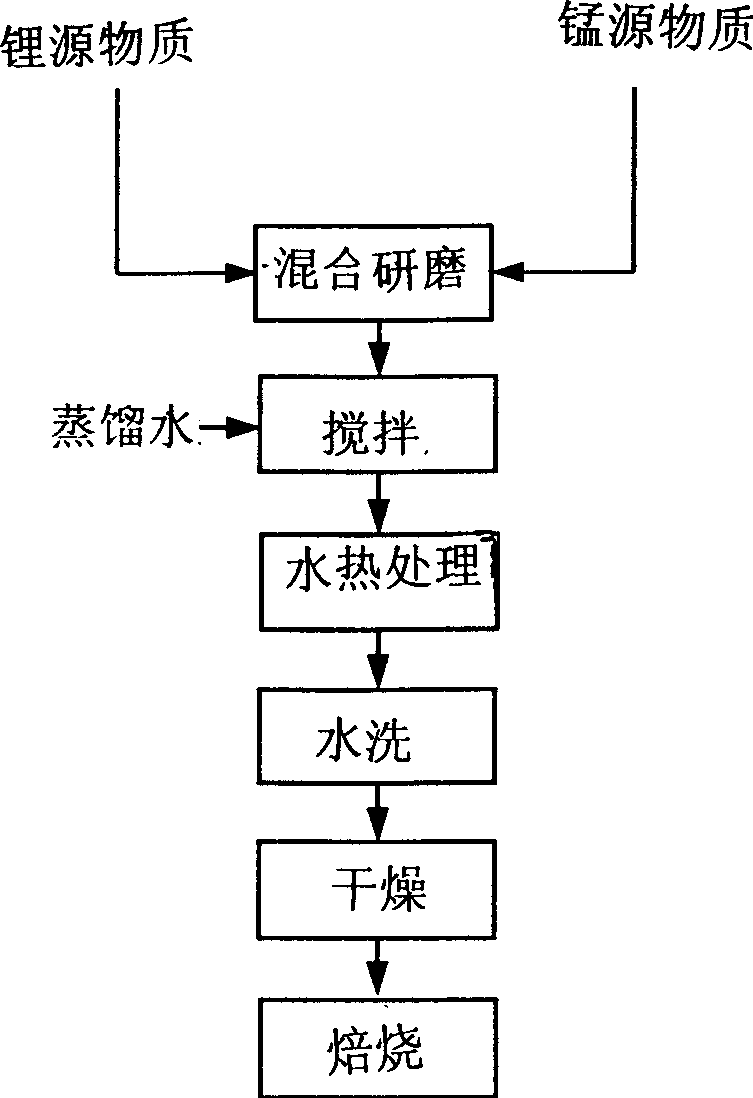

Method used

Image

Examples

Embodiment 1

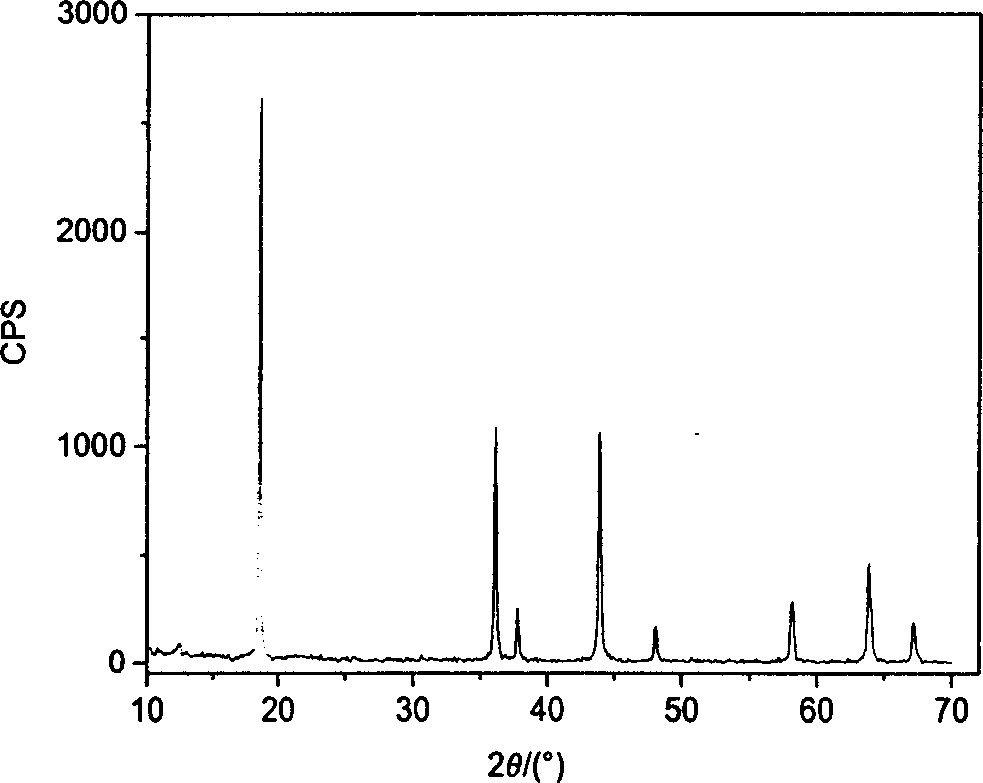

[0021] Embodiment 1: Accurately weigh analytically pure (CMD) MnO2 8.6940g, analytically pure LiOH·H 2 O 4.1960g, after mixing the two, grind them with agate at room temperature and transfer them to a 50mL hydrothermal reaction kettle, add 25mL of distilled water, seal the hydrothermal reaction kettle after stirring vigorously for 5min, put it into a constant temperature oven at 160°C for 48h, take it out and cool it naturally After filtering, wash with distilled water until the filtrate PH=8, the obtained solid is dried at 100°C and sent to a high-temperature furnace for pre-calcination in an air atmosphere at 300°C for 2 hours, and then roasted in an air atmosphere at 600°C for 12 hours. Furnace cooling, the resulting product has uniform particle size, detected by XRD, its characteristic diffraction peak (see attached figure 2 ) and LiMn with spinel structure on the JCPDS diffraction card 2 o 4 The characteristic diffraction peaks are completely consistent and the peak in...

Embodiment 2

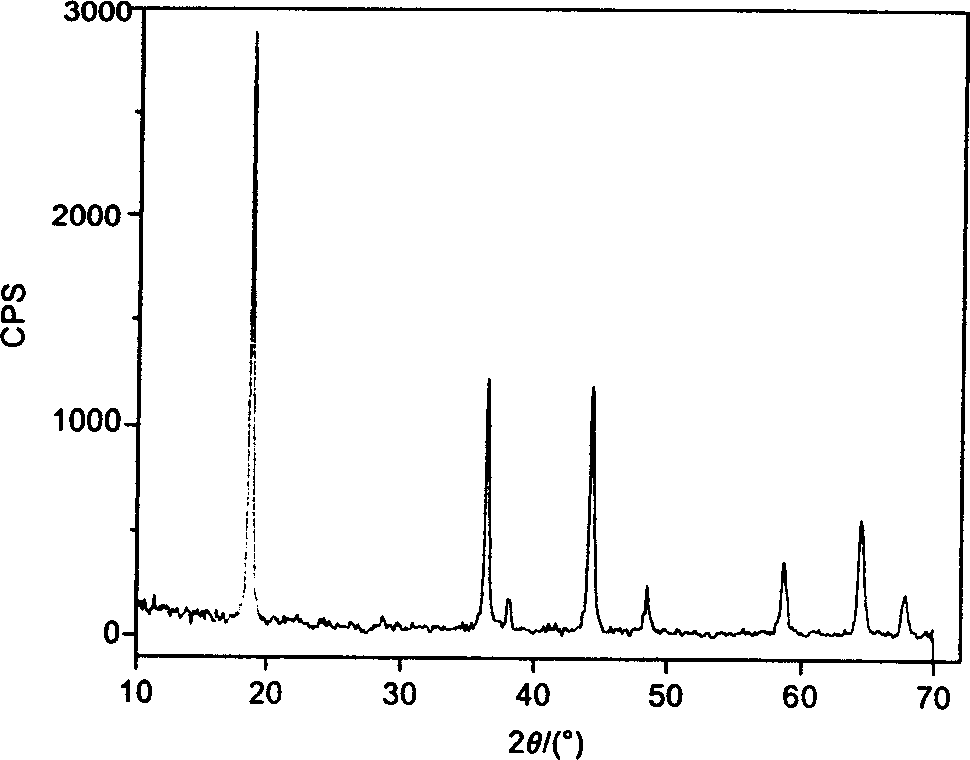

[0022] Embodiment 2: Accurately weigh analytically pure Mn 2 o 3 7.8940g, analytically pure LiOH·H 2 O 5.0352g, after the two are mixed, grind with agate at room temperature and then transfer to a 50mL hydrothermal reaction kettle, add 30mL of distilled water and stir vigorously for 5min, then seal the hydrothermal reaction kettle, and then send it to 140°C for 3

[0023] Insulate in a warm oven for 72 hours, take it out to cool naturally, filter, wash with distilled water until the filtrate pH = 7.5, dry the obtained solid at 105°C, send it to a high-temperature furnace for pre-calcination in an air atmosphere at 300°C for 2 hours, and then heat it at 700°C After roasting in the air atmosphere for 12 hours, the sample was cooled with the furnace, and the obtained product had a uniform particle size. The characteristic diffraction peaks (see attached image 3 ) and LiMn with spinel structure on the JCPDS diffraction card 2 o 4 The characteristic diffraction peaks are comp...

Embodiment 3

[0024] Example 3: Accurately weigh 8.7940 g of analytically pure γ-MnOOH, analytically pure LiOH·H 2 O 12.5880g, after mixing the two, grind them with agate at room temperature and transfer them to a 100mL hydrothermal reaction kettle, add 60mL of distilled water, seal the hydrothermal reaction kettle after stirring vigorously for 5min, put it into a constant temperature oven at 120°C for 24h, take it out and cool it naturally After filtration, wash with distilled water until the filtrate PH=8, the obtained solid is dried at 80°C and sent to a high-temperature furnace for pre-calcination in an air atmosphere at 300°C for 2 hours, and then roasted in an air atmosphere at 500°C for 8 hours. Furnace cooling, the resulting product has a uniform particle size, detected by XRD, characteristic diffraction peaks (see attached Figure 4 ) and LiMn with spinel structure on the JCPDS diffraction card 2 o 4 The characteristic diffraction peaks are completely consistent and the peak inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com