A kind of harmless treatment method of cyanide tailings

A technology of harmless treatment and cyanidation of tailings, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as high anti-corrosion ability, pollution, and large land occupation, and achieve Good effect of removing cyanide and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

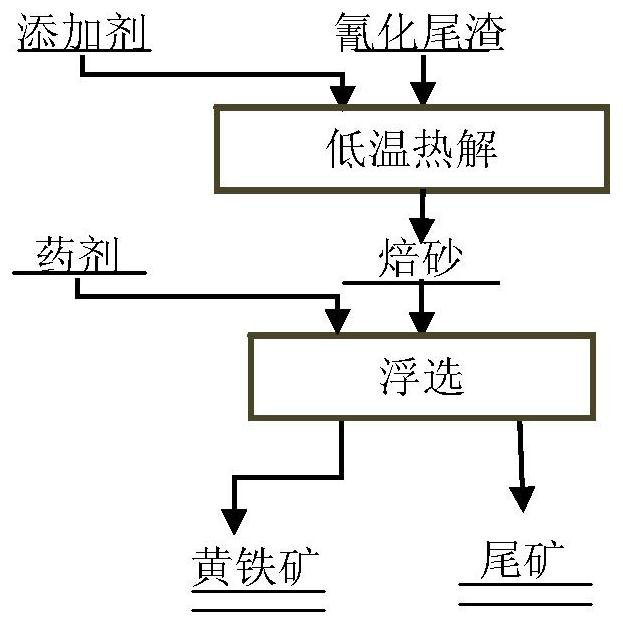

Method used

Image

Examples

Embodiment 1

[0027] The cyanide tailings are cyanide tailings produced by a company in Shandong, the mass percentage of water is 12.4%, and the solid content contains Fe 41.41%, S 48.40%, SiO 2 5.72%, Al 2 o 3 1.48%, CaO 0.47%, CN — Content 340mg / kg;

[0028] Prepare cyanide tailings as raw material;

[0029] Heat the raw material to 250°C for pyrolysis, and heat it for 90 minutes after reaching 250°C to complete the pyrolysis to remove cyanide and obtain calcined sand;

[0030] Use calcined sand directly for backfill treatment;

[0031] After testing, it was found that the total cyanide in the cyanide tailings (in CN — Count) gradually decreases, and at the end of pyrolysis, the pyrolysis material basically does not contain cyanide, CN — It is almost 0, and the cyanide removal rate reaches more than 99%.

Embodiment 2

[0033] Method is with embodiment 1, and difference is:

[0034] (1) The mass percentage of water in the cyanidation tailings is 16.9%, and the solid content contains Fe 29.92%, S 33.30%, SiO by mass percentage 2 24.95%, Al 2 o 3 5.25%, CaO 1.15%, CN — Content 500mg / kg;

[0035] (2) Heat the raw material to 350°C for pyrolysis, and heat it for 15 minutes after reaching 350°C to complete the pyrolysis;

[0036] (3) Add water to the calcined sand to make a pulp with a mass concentration of 35%; add flotation agent xanthate, foaming agent and inhibitor to the pulp, and then carry out flotation; wherein the amount of xanthate added is based on the amount of xanthate in the pulp The concentration is 0.5×10 -5 mol / L, the addition of foaming agent is 100mg / L by the concentration of foaming agent in the ore pulp, and the addition of suppressor is 100g / t calcine; Described foaming agent is 2# oil, and described The inhibitor is water glass; the flotation temperature is 15° C. an...

Embodiment 3

[0038] Method is with embodiment 1, and difference is:

[0039] (1) The mass percentage of water in the cyanidation tailings is 23.7%, and the solid content contains Fe 29.92%, S 33.30%, SiO by mass percentage 2 24.95%, Al 2 o 3 5.25%, CaO 1.15%, CN — Content 1160mg / kg;

[0040] (2) Heat the raw material to 450°C for pyrolysis, and complete the pyrolysis after reaching 450°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com