Automatic loading-unloading line for workpiece machine tool machining

A technology of automatic loading and unloading and machine tools, which is applied in metal processing and other directions, can solve problems such as the impact on the output of the entire line, and achieve the effects of increasing daily output, saving production costs, and reducing man-hour requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

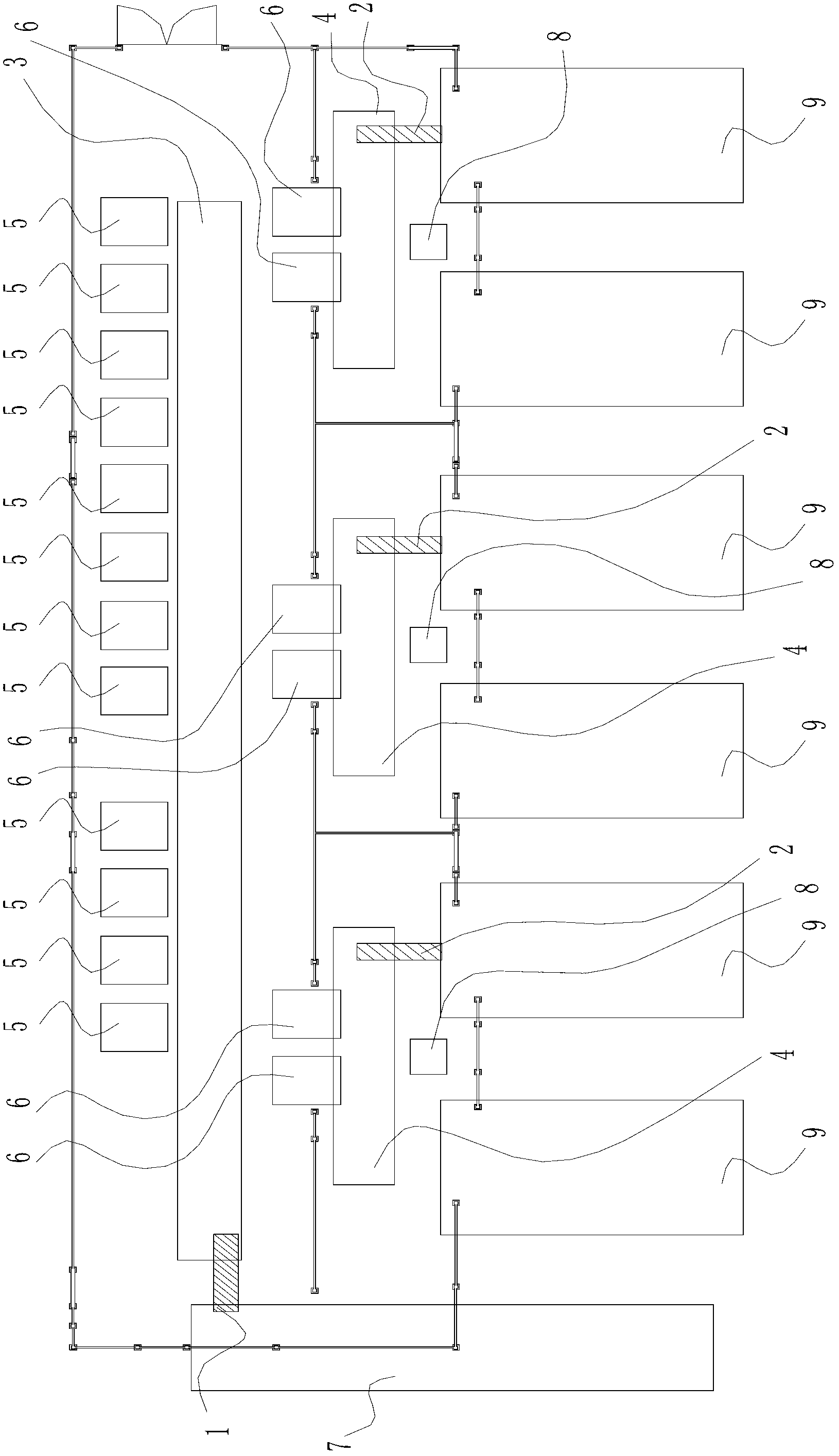

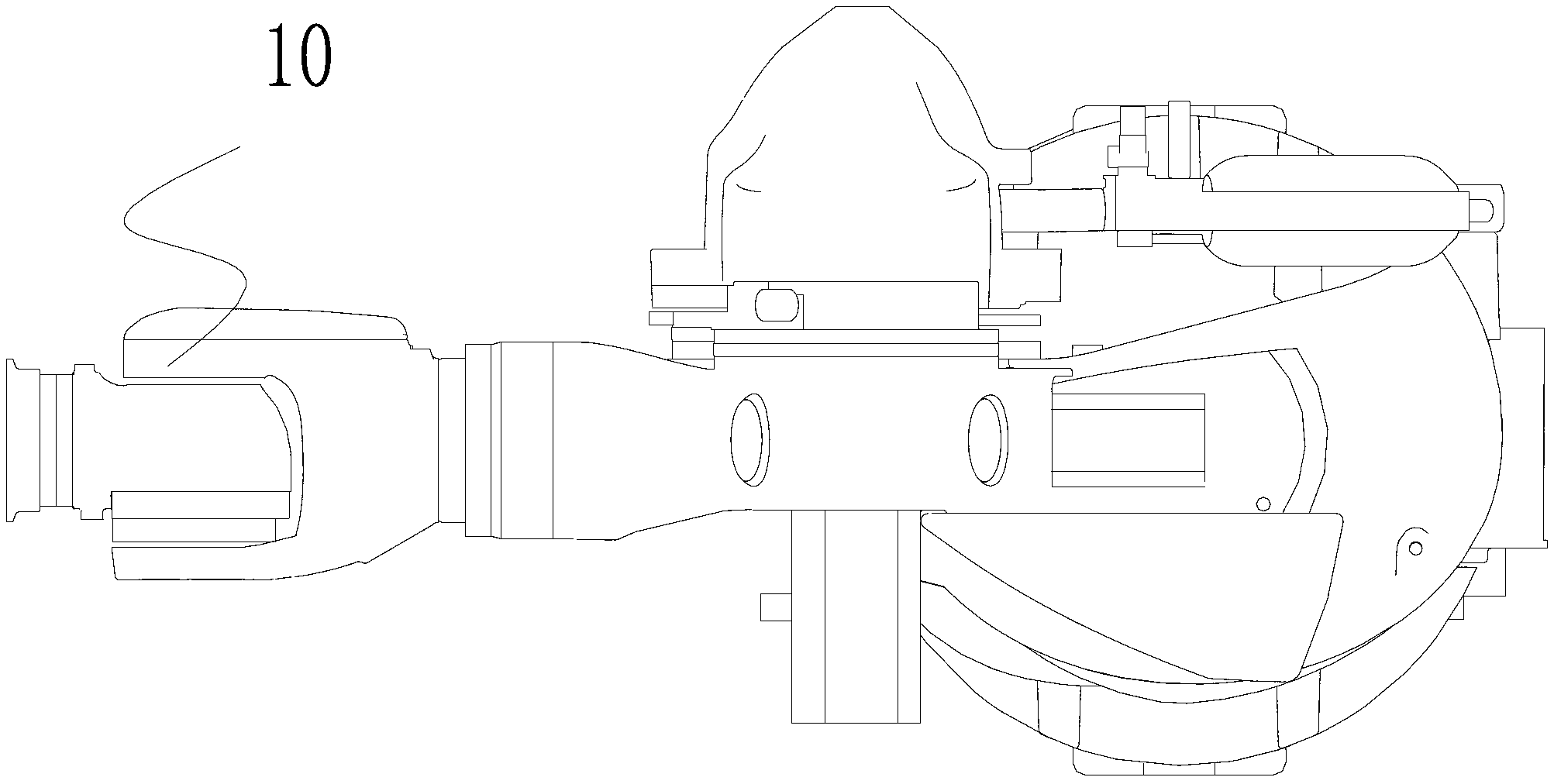

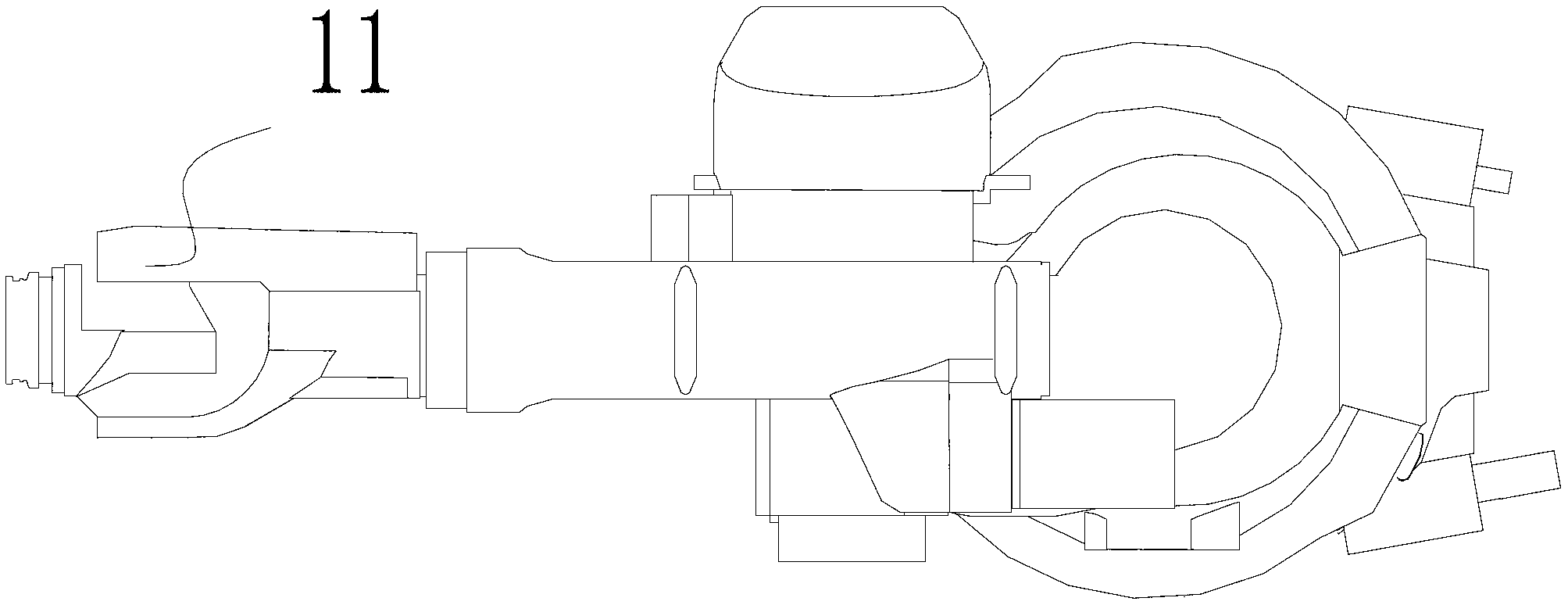

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , an automatic loading and unloading line for workpiece machine tool processing in the present invention, comprising a first robot 1, a second robot 2, a first transfer mechanism 3, a second transfer mechanism 4, a logistics buffer area 5, a robot loading and unloading area 6, and a manual The loading and unloading area 7, the chamfering equipment 8, the machine tool 9 and the electric control system, the first robot 1 is provided with a gripper 10, the second robot 2 is provided with a gripper 11, the manual loading and unloading area 7 is provided with a conveying device, the electric control system Including PLC safety module 14 and touch screen HMI13.

[0031] The first robot 1 is installed on the first transfer mechanism 3, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com